Features:

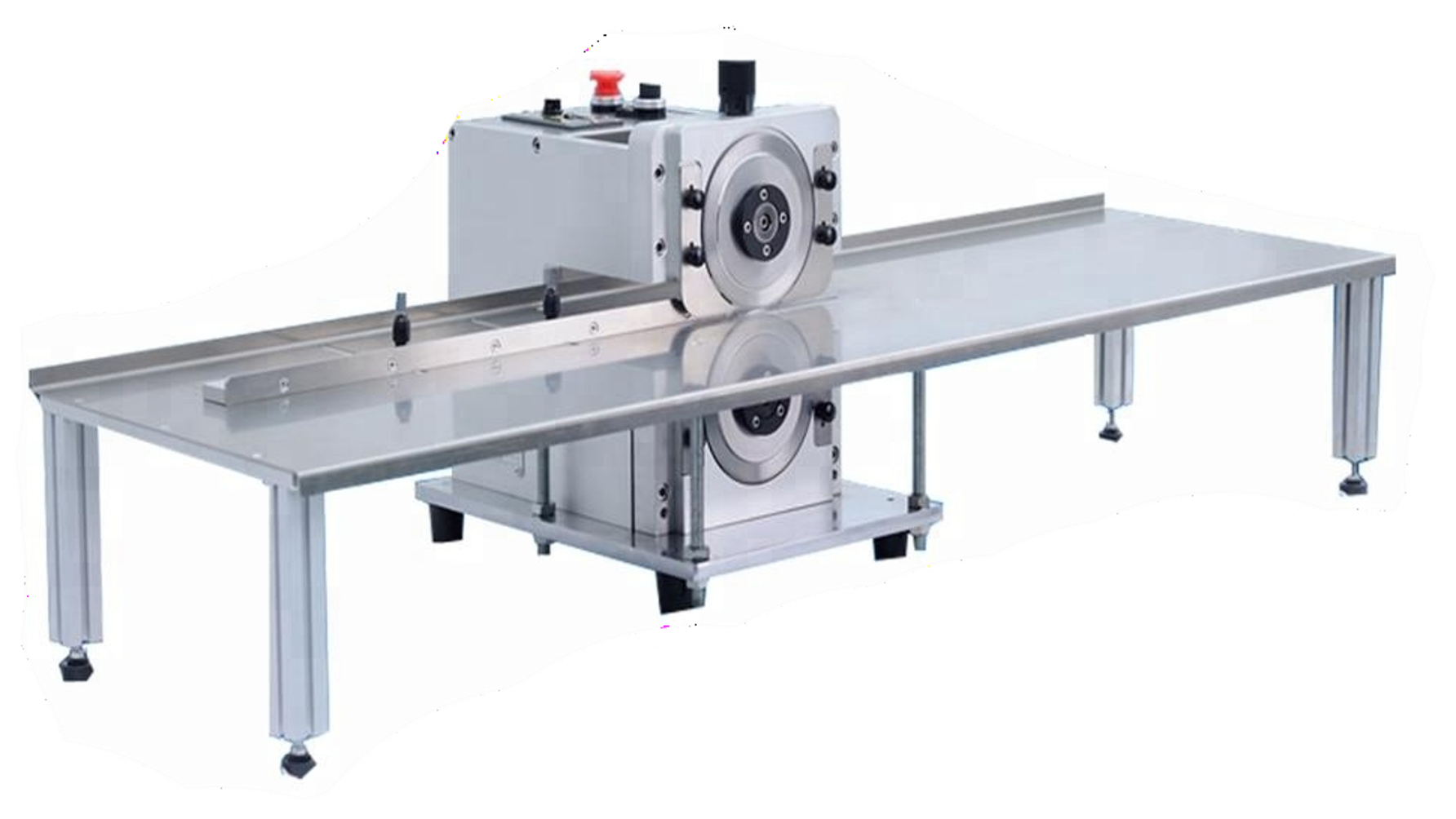

Dual worktables, high efficiency.

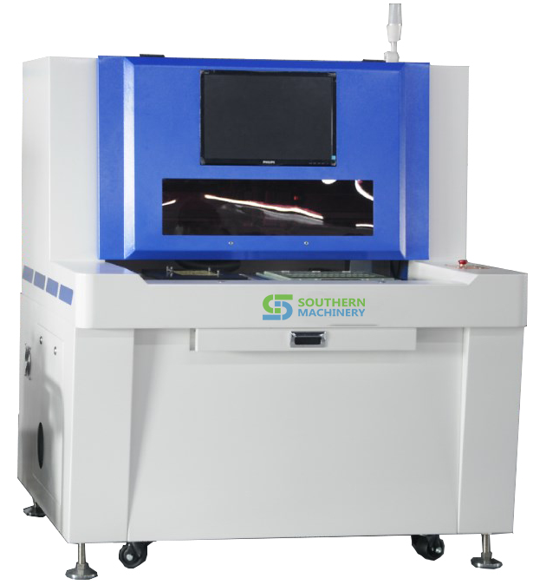

Automatic MARK point correction.

Automatic QR code scanning, MES interface.

Upper and lower dust suction mode, good dust collection effect.

Production records collected in real time.

The PCB is more firmly fixed during cutting to avoid cutting accuracy errors caused by poor PCB positioning.

Whole board image scanning and stitching.

Special fixture for easy fixing of products to be cut to ensure high precision cutting requirements.

Anti-static generator attached to the front of the main shaft during cutting to continuously blow air, reduce static electricity generated during high-speed main shaft cutting, and avoid damage to parts caused by static electricity.

Using safety doors, reducing noise and dust, and improving safety. The dust collector comes with a dust box.

Contact details:

Welcome to contact and get more information:

Email: jack@smthelp.com

Skype:+86 15622888481

Whatsapp/WeChat: +86 15622888481