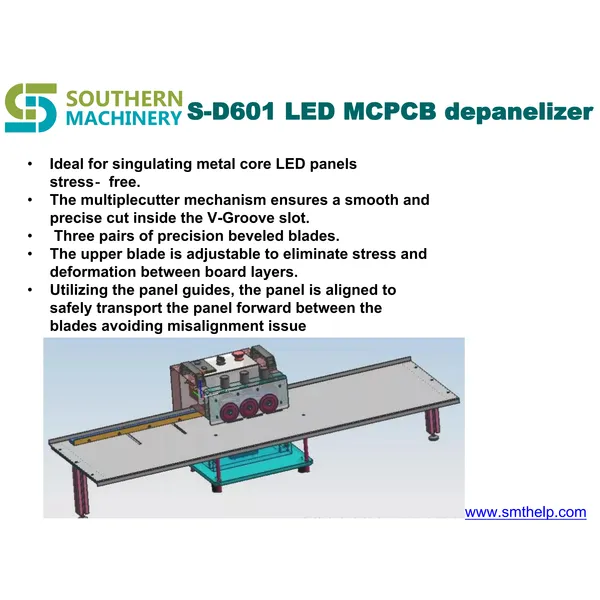

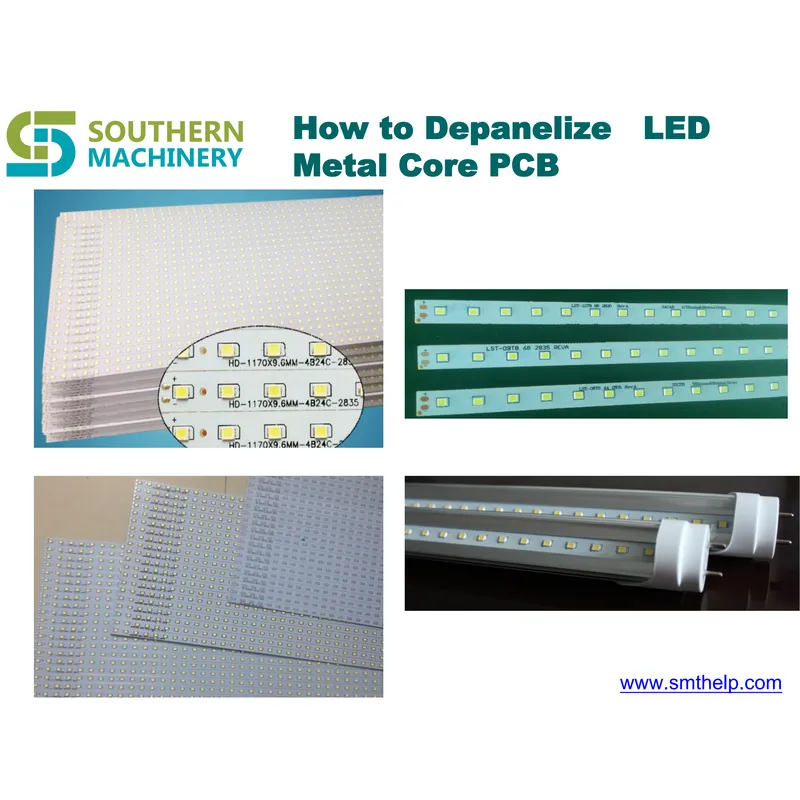

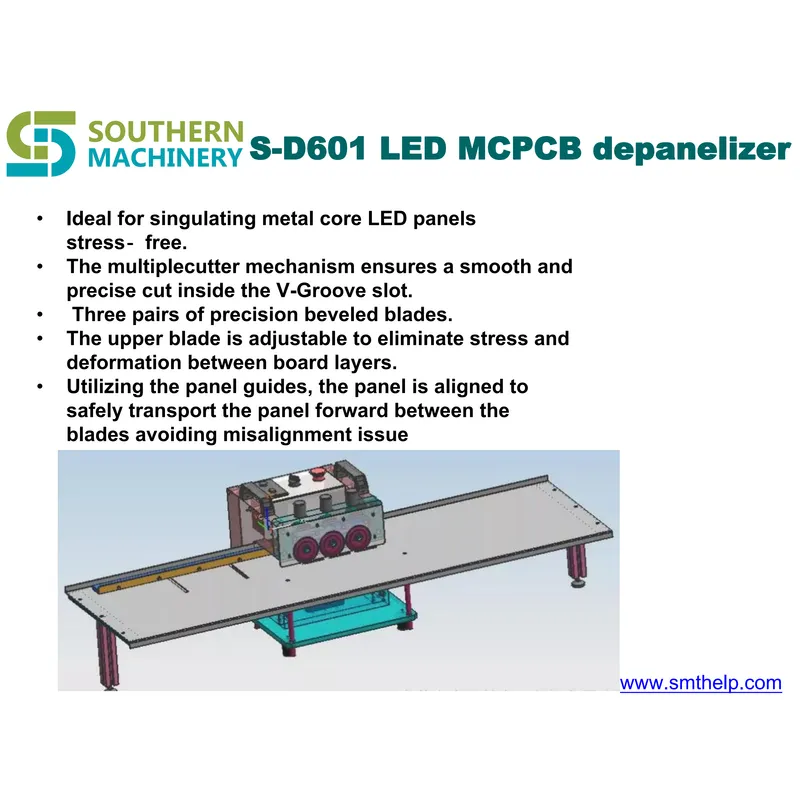

Ideal for singulating metal core LED panels stress‐free.

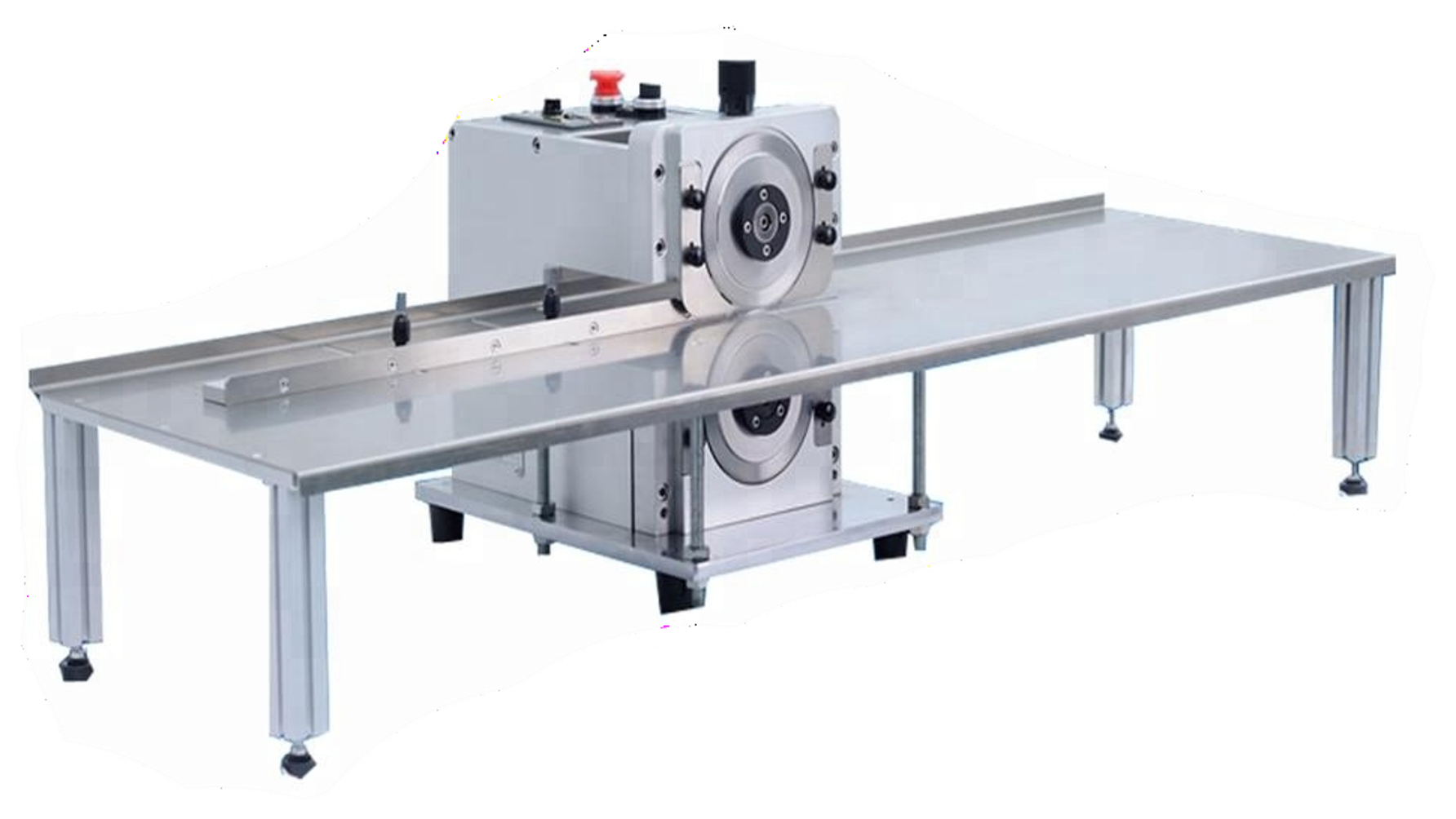

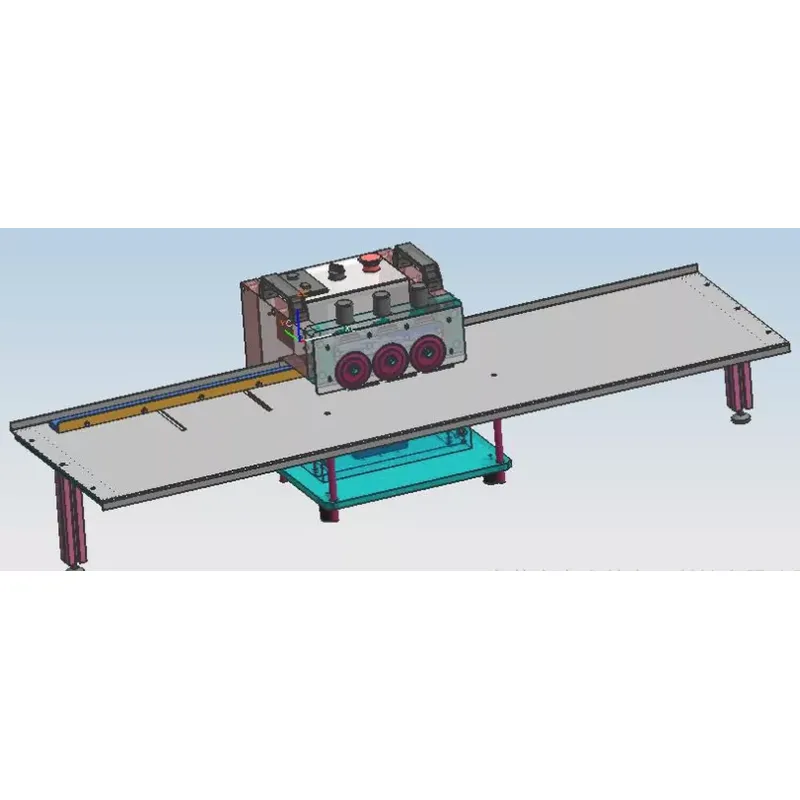

The multiplecutter mechanism ensures a smooth and precise cut inside the V-Groove slot. Three pairs of precision beveled blades.

The upper blade is adjustable to eliminate stress and deformation between board layers.

Utilizing the panel guides, the panel is aligned to safely transport the panel forward between the blades avoiding misalignment issue

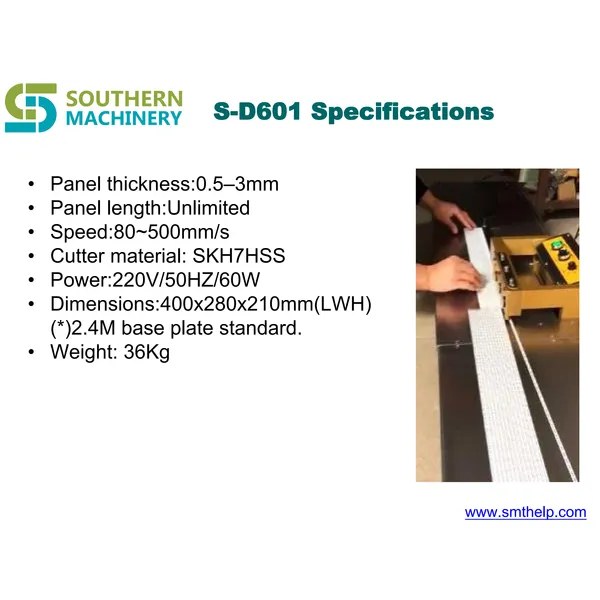

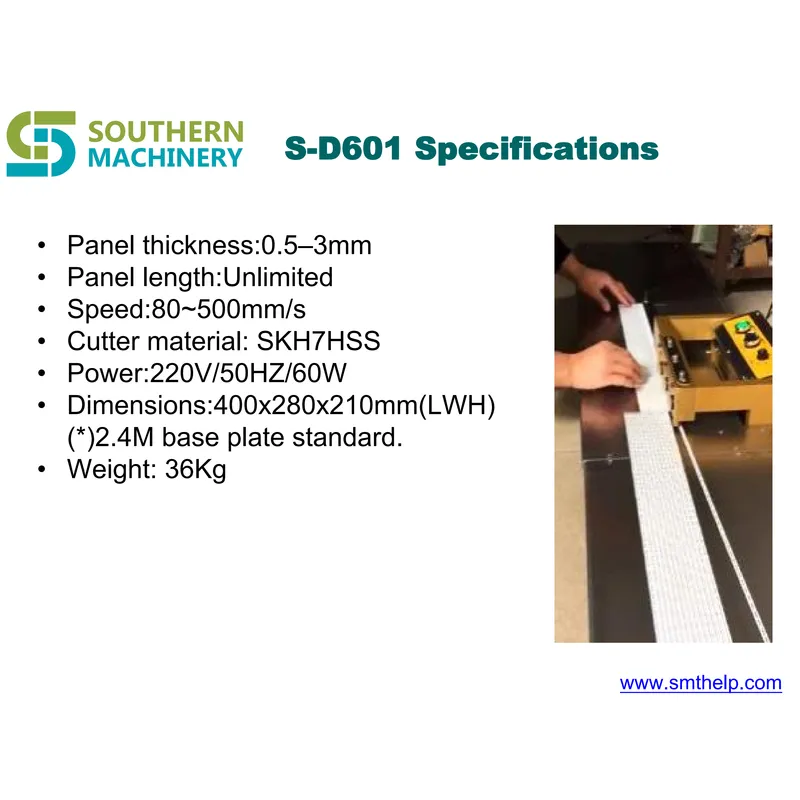

Panel thickness:0.5–3mm

Panel length:Unlimited

Speed:80~500mm/s

Cutter material: SKH7HSS

Power:220V/50HZ/60W

Dimensions:400x280x210mm(LWH)(*)2.4M base plate standard.

Weight: 36Kg