Feature

It is suitable for all kinds of electronic industry, which mainly solves the bad situation of products produced by manual breaking off.

1, PCB could be taken off automatically after work is finished, this machine could communicate directly with the front machine, such as SMT Magazine Loader.

2, PCB would be put on the machine for working by professional fixture, to avoid the error caused by the wrong position.

3, Self-correction on the error of PCB installation, make sure it matches request of high accuracy.

4, Static eliminator applicated to clear static generated during high-speed shear of the main bearing, which is able to avoid damage and dust piled up by static.

5, Safe door for isolation from noise and dust.

6, Touch screen to display, set, and control, simple operation.

7, Able to connect with feeding equipment, and divide them onto a plate.

8, Professional Automatic Curve PCB Cutter for Stamp PCB.

Specification

| Function Items | Hardware Demand |

| Model | S-D3500S(with belt) |

| Dimension | (with belt)L1750*W1100*H1850mm;(without belt)L1450*W1100*H1850mm |

| Power | 220V/50HZ |

| Machine Wattage | 5.5KW |

| Weight | About1000KG |

| Gas consumption / per hour | 0.000016*3.14*25*3600=4.5216 |

| Power consumption / per hour | 5.5KW/H |

| Cleaner Dimension | (built-in)/L450*W450*H450mm |

| Cleaner Wattage | 2.2KW |

| Table Dimension | 350mm*350mm |

| Cutting Speed | 0-100mm/s |

| X,Y,Z axis Driving Speed | X、Y axis 1000mm/s(min),Z axis750mm/s(min),driven by servo motor |

| Repeatability Accuracy | ±0.02mm |

| Mechanical hand X, Z stroke | X:420mm、I:60mm |

| Manipulator X, Z running speed | 200mm/s |

| Mechanical hand grasp mode | by vacuum |

| Precision of repeated positioning of manipulator | ±0.04mm |

| Mechanical hand grab products (PCB) dimensions | 350mm*350mm |

| PCB feeding track | By belt;W:60~360mm |

| Split plate product | By belt;W:420mm |

| Working Area | X:300mm,Y:350mm,Z:0-50mm |

| PCB Thickness | 0.5-2mm(or thicker) |

| Router Bit Diameter | 0.8-2.0mm |

| Cutting Precision | ±0.01mm |

| Cutting Ability | Linear, Circular, U-curve, Arc, L-curve |

| Cutter Change | Automatic tool changing system |

| Cutter Attrition System | Smart to set the no. of knife section(0-3) |

| Break Detection function | YES |

| Cutter Life Control | controlled by Program |

| Product testing function | YES |

| Table Number | 1 |

| Table Function | 1 table run in parallel |

| Spindle Speed | 60000rpm |

| Spindle Cooling System | air cooling |

| Cleaner Mode | collect dust in downside |

| Working Power | 220V ,50HZ |

| Air press | 0.5Mpa以上(above) |

| Safety Device | security door with sensor |

| Mode | online,auto load and unload PCBA |

| Auto failure test and repair mode | Self-diagnosis,display failure information in real time, query IO state visually, easy for troubleshooting |

| Computer & Operation system | PIC、Windows 7 or more advanced version |

| Program Backup | USB |

| Software access control | Password protection,the operator enter corresponding interface according to authority to protect important parameters |

| Programming | Visual interface, the cutting point capacity for a single program should be over 400, dynamic simulation of cutting schedule |

| Auto correction of the mark point | Yes |

| Fixture | special fixture |

| Voice control | ≦78 dB(measured in 1Meter ) |

| Maintenance Period | Over 1 year for the whole machine, and over 2 years for the spindle, and the spindle enjoys 3000 hours’ maintenance during the period |

| Technology Support | Offer service of operation, programming, hardware caring and maintenance training; free upgrade of application |

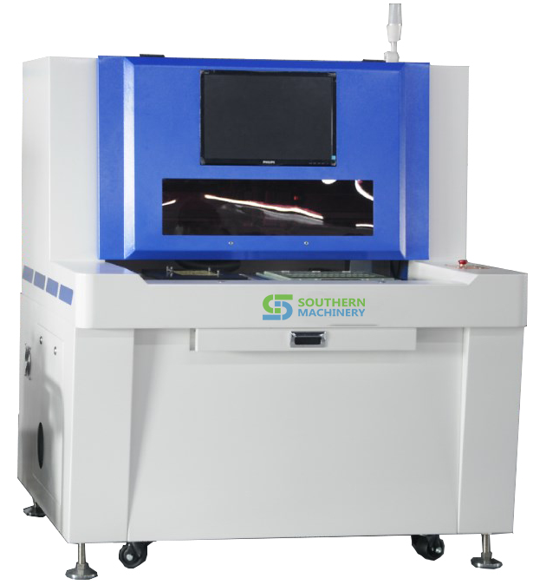

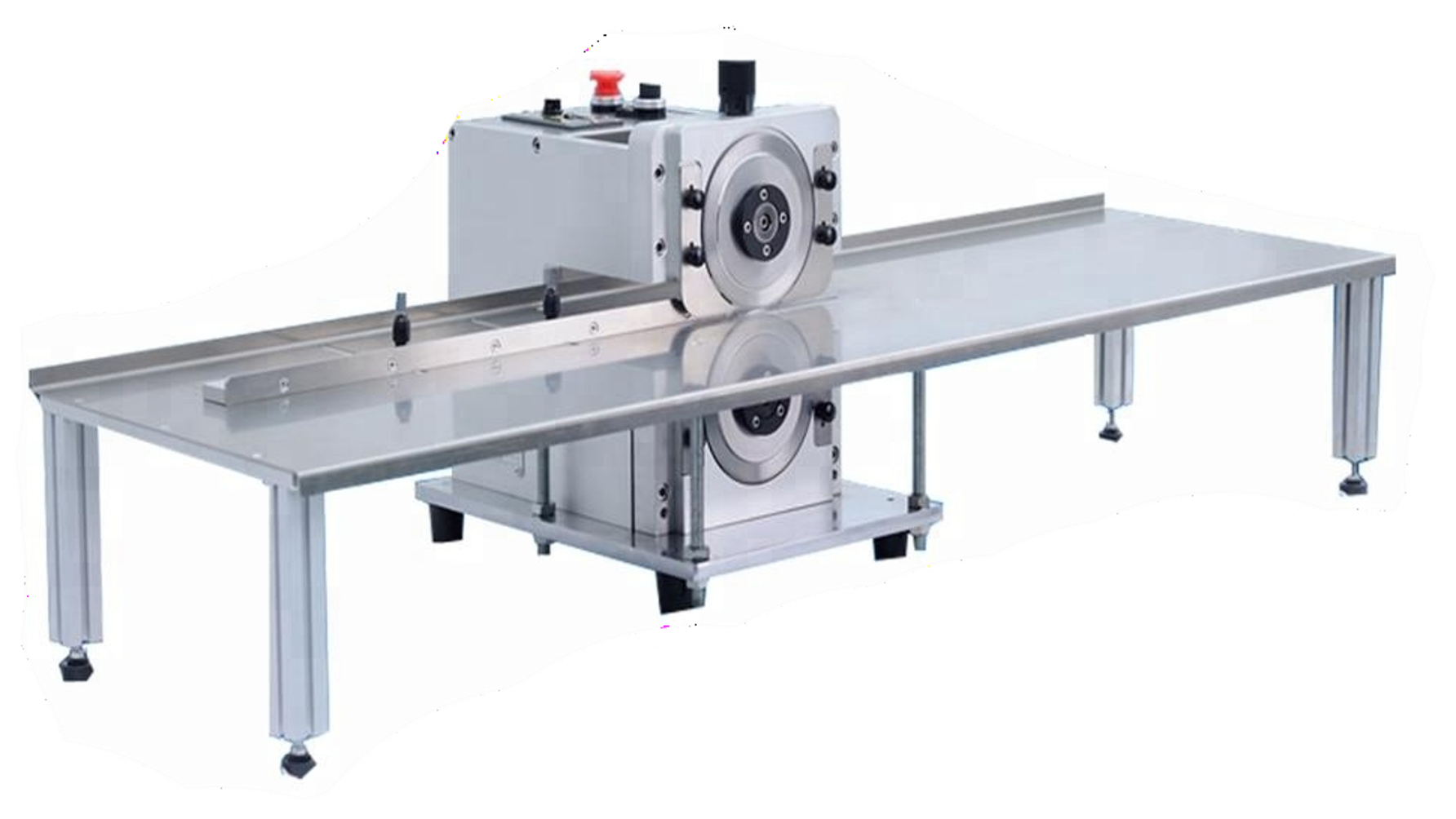

S-D3500S Online Routing PCB Separator

S-D3500S Online Routing PCB Separator

S-D3500S Online Routing PCB Separator

S-D3500S Online Routing PCB Separator S-D3500S Online Routing PCB Separator

S-D3500S Online Routing PCB Separator