Description

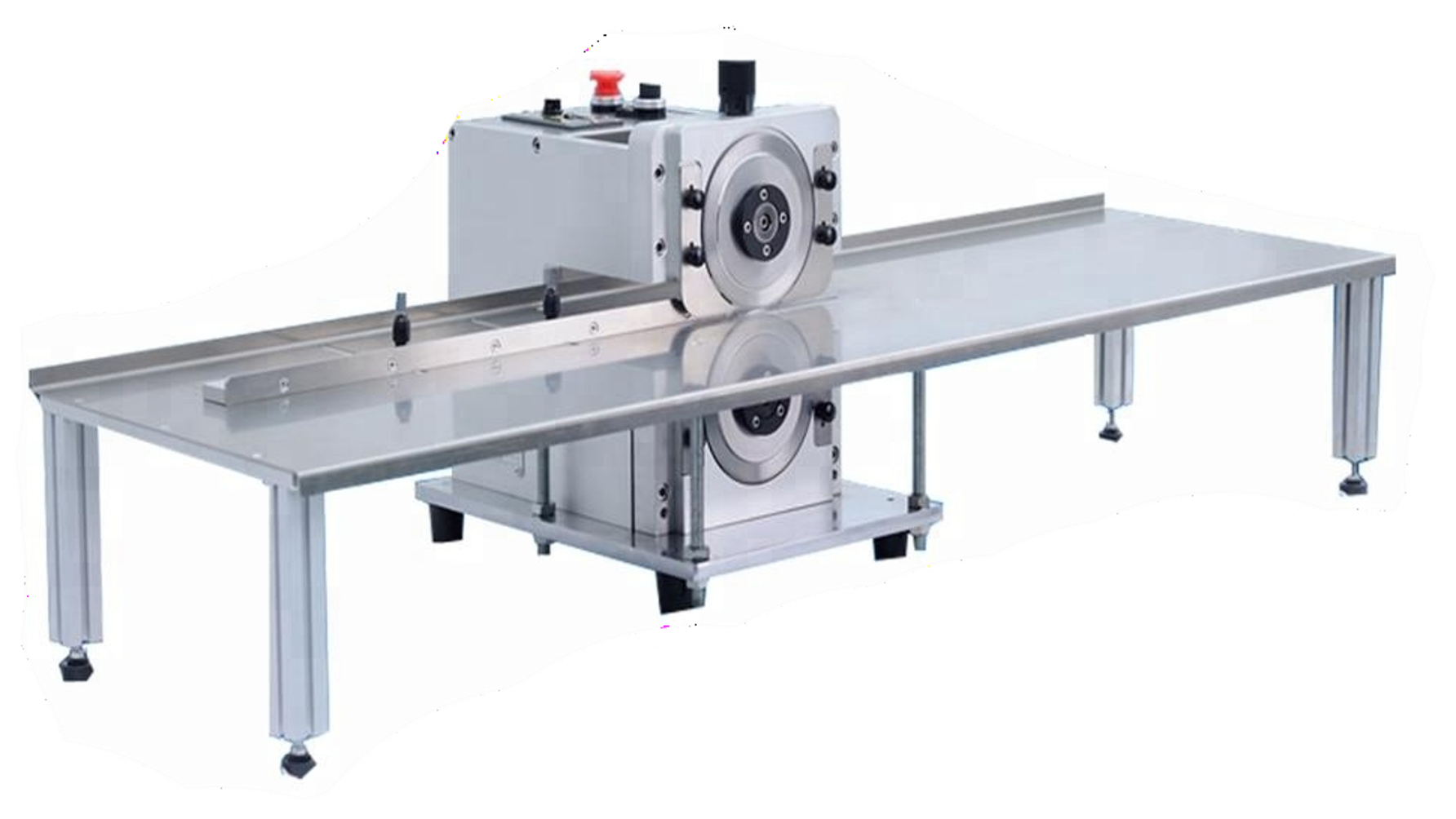

It is suitable for all kinds of electronic industry, which mainly solves the bad situation of products produced by manual breaking off.

Features

1,Using the upper / lower dust absorption mode, a reasonable plan can be customized according to the customer’s requirements, and the dust collection effect is good. (upper and lower vacuum can not be interchangeable).

2, the base plate is fixed more firmly in the cutting, avoiding the cutting accuracy error caused by the bad basic positioning.

3.The special tool is made. It is easy to fix the products to be cut, so as to ensure the high precision cutting requirements.

4, when cutting the main shaft of the main shaft with antistatic generator constantly blowing gas, reducing high speed spindle cutting to produce static electricity, can avoid the damage caused by static electricity.

5, use safety door, reduce noise and dust, improve safety. The vacuum cleaner is attached with a vacuum box (according to the capacity cutting demand or dust collection time for maintenance).

6,PCB could be taken off automatically after work is finished, this machine could communicate directly with front machine , such as SMT magazine Loader.

7,PCB would be put on machine for working by professional fixture, to avoid error caused by wrong position.

8,Self-correction on error of PCB installation, make sure it matches request of high accuracy.

9,Static eliminator applicated to clear static generated during high speed shear of main bearing, which is able to avoid damage and dust piled up by static.

10,Safe door for isolation from noise and dust.

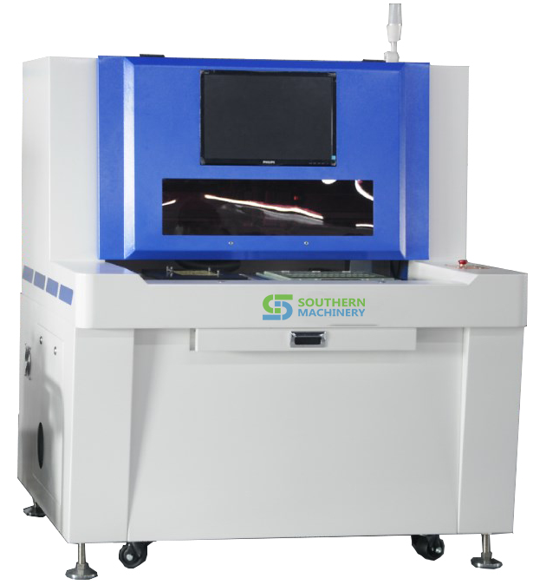

11,Touch screen to display, set and control, simple operation.

12,Able to connect with feeding equipment, and divide them onto plate.

13,Professional Automatic Curve PCB Cutter for Stamp PCB

Specifications

| Machine size | L1400mm*W1200mm*H1600mm |

| Shear Speed of X,Y axis | 0-100mm/s,max1000mm/s |

| Drive speed of X,Y,Z axis | X、Y axis at least 700mm/s,Z axis at least 300mm/s, by motor drive servo |

| Accuracy of Repeat | ±0.02mm |

| Work Area | X:350mm,Y1:330mm,Y2:330mmZ:0-50mm |

| PCB Thickness | 0.5-2mm,or specify |

| Shear Ability | capable of shear of straight line, arc, circle, L and U shape |

| Blade wear | set milling tool by intelligence |

| Table Fuction | SingleTable,left and right Table works alternantly, two Tables can work simultaneously |

| Main axis speed& cool down | 60000rpm & By cold wind |

| Dust collection and power | Built-in dust collector, 3.7kw 380v three phase motor |

| Power Supply | 380V ,50HZ |

| Pressure Supply | 0.45Mpa up |

| Security Device | apply safe door or inductor |

| Working Mode | PCBA off line, load and unload PCBA manually |

| Operation Inteface | Windows7, Online program |

| Visual System | CCD Visual alignment system |

| Weight | Approx 780kg |

| Max.PCB Thickness | 4mm |

| Power (included dust collector) | 5000w |

| Max Rotation Speed | 60000rpm/min |

| Milling | Milling by left rotation, DIA of 0.8-3.0mm optional |

| Error Record | automatic memory on all error |

| Shear Qty Counting | Counter on shear quantity and Time recording |

| Main axis life Tracking | Automatic Inspection on Life of main axis |