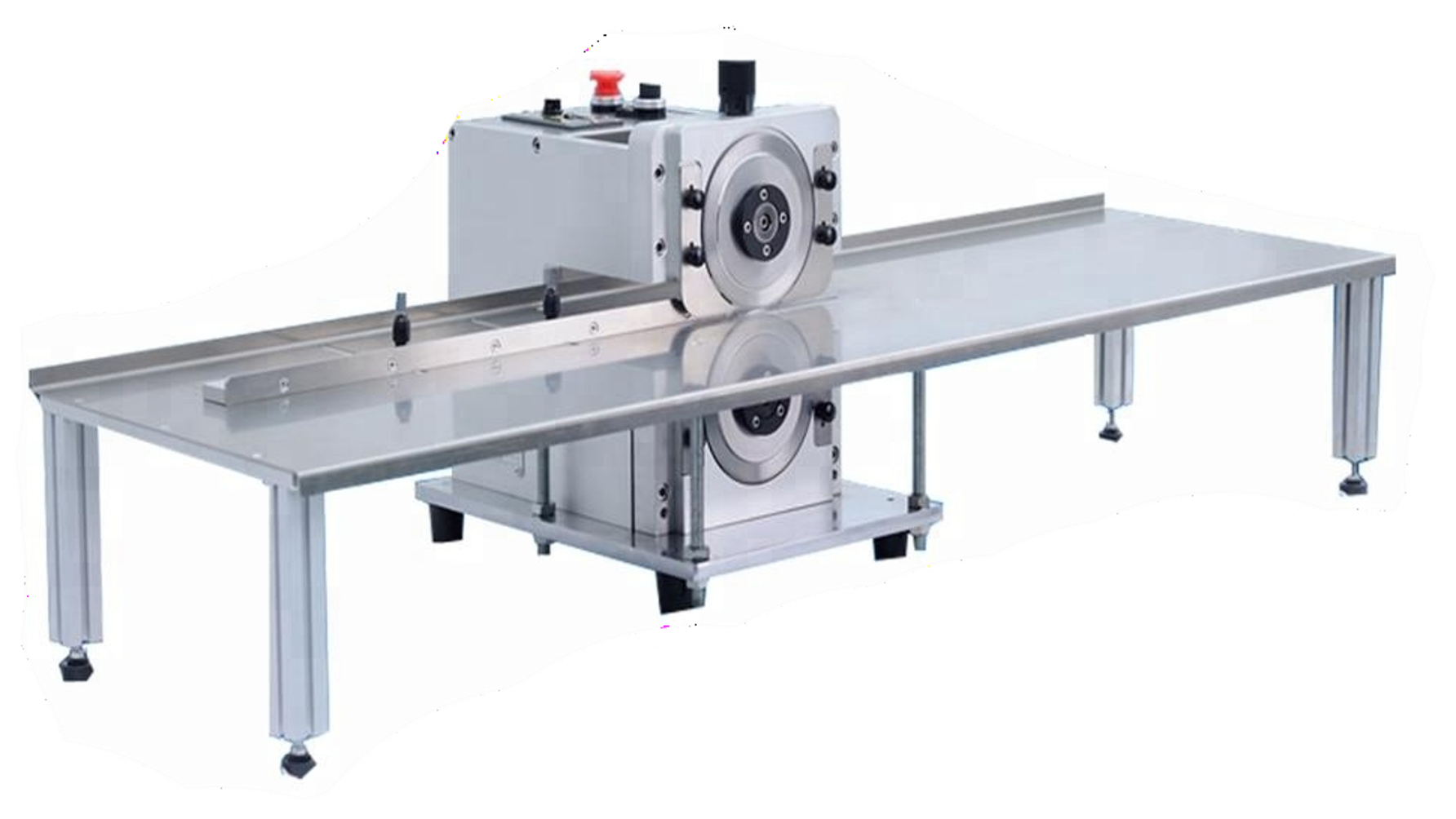

Description

It is suitable for all SMT with V-CUT. PC board (base plate).

Features:

1) The imported linear slide way, the upper round knife and the lower straight knife are used to segment the V-CUT base plate, so as to reduce the cracks of SMT solder joints;

2) The highest component on PCB near V-CUT is 10-20mm, with unlimited width;

3) Can be adjusted according to different thickness of PC board;

4) Especially suitable for the segmentation of thin PCB.

5) It does not need power, has environmental protection function, easy to operate.

6) Blade is made by professional factory of tai-wan, the material is the high speed steel from Japan.

Specifications:

| Model | S-D510 |

| Machine Size(L*W*H) | 820 x 390 x 360mm |

| Max cutting length | Max 350mm |

| Cutting Speed | 0 to 400mm/s |

| Cutting thickness | 1.0 to 3.5mm |

| Operation Type | Manual |

| Machine Weight | 50kg |

Tool Material: SKD61 imports of high-speed steel, the round knife: diameter 125mm, the next straight knife length: 350mm

Customers FAQ About PCB Separator SC-510:

Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.Q:What is warranty of the machine?

A:1 year.Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe transportation.Q:What is life time of machine blades?

A:About 6-12 months.Q:What is material of blades?

A:Japan high speed steel SKH-9Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client if needs.Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who are using our machines.

Contact details:

Welcome to contact and get more information:

Email: wayne@smthelp.com

Skype:waynesmt@outlook.com

Whatsapp/WeChat: +86 15817498429