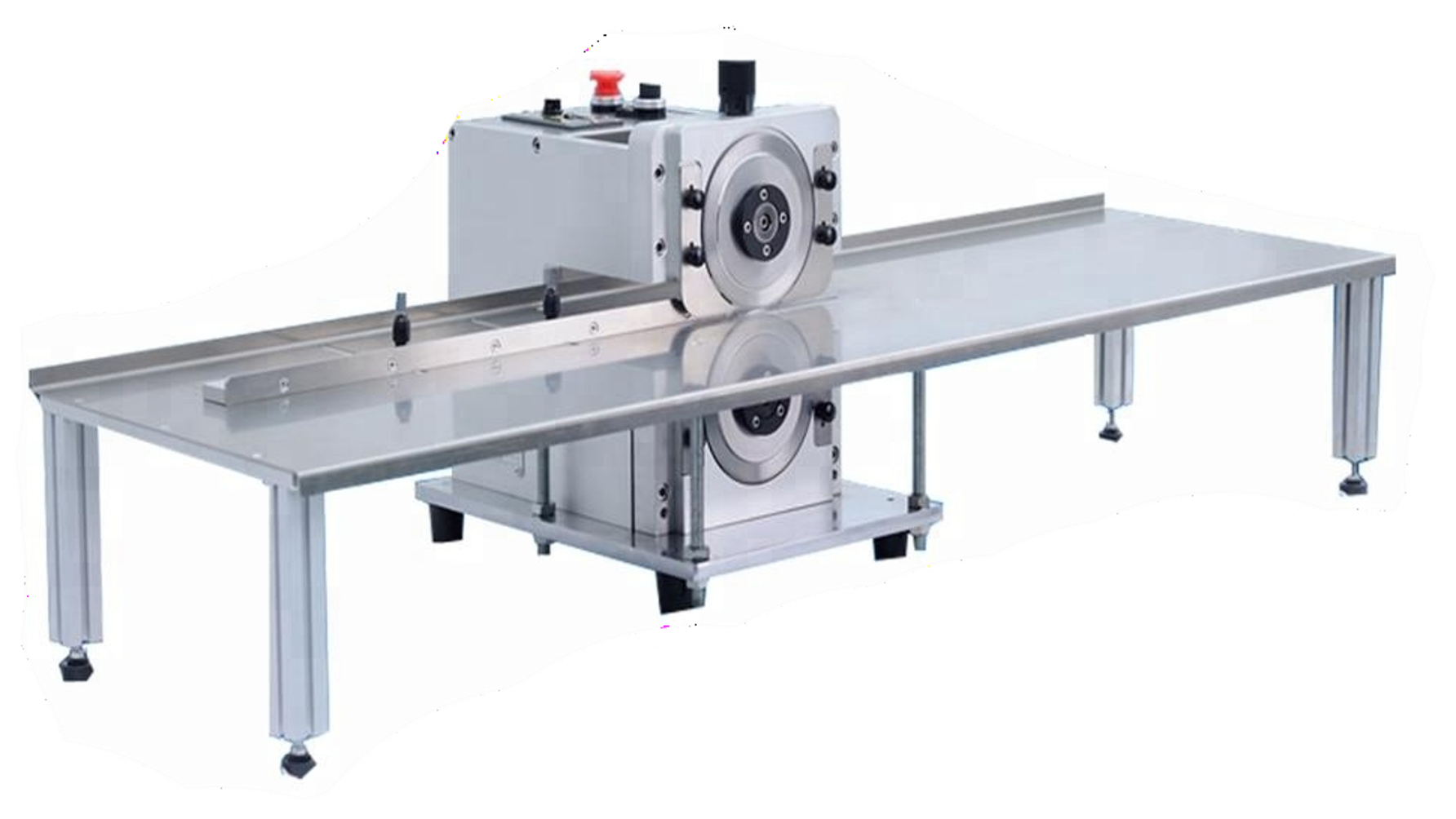

It is suitable for all kinds of V-cut PCB, which mainly solves the bad situation of products produced by manual breaking off.

Auto PCB Depaneling machine V-Cut Separator is workable for LED stripes, it can separate up to 20 PCBs simultaneously that mainly uses for the PCB assembly in the large mass production with the high efficiency and saves a lot of labor for the manufacturer.

Features:

Depaneling speed is adjustable by manual

Depaneling by circular blades, dust or residue generates; drive by motor, less pollution.

The blade is made by a professional factory in Taiwan, the material is high-speed steel from Japan.

House of PCB Depaneling machine is made by Al-alloy and finishes in one time, simple and swift operation

Up & Down Blade of PCB Depaneling machine is able to be adjusted accurately,

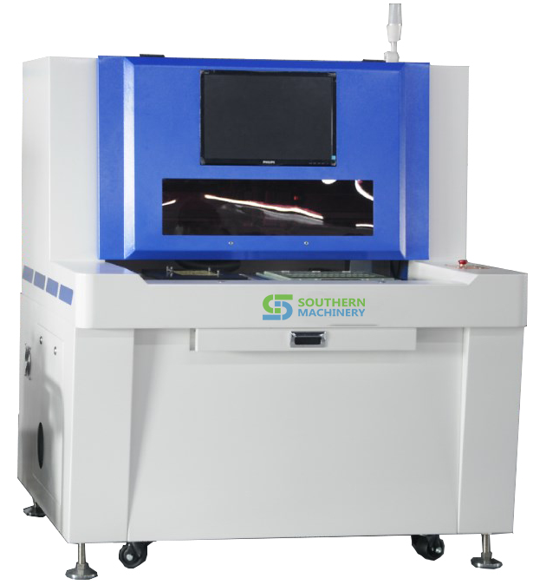

Specialized Automatic V-cut PCB Depaneling Machine for LED Boards with long Platform.

Specifications:

| Model | S-D505 | S-D506 |

| Machine Size(L*W*H) | 1100x730x630 mm | 1400x550x1105 mm |

| Max cutting length | 0~360mm | 0~360mm |

| Cutting Speed | 80~500mm/S | 80~500mm/S |

| Cutting thickness | 0.2-5mm | 0.2-5mm |

| Working Voltage | 230V/50H(110V/60Hz) | 230V/50H(110V/60Hz) |

| Machine Weight | 137 kg | 137 kg |

Customers FAQ About PCB Separator S-D505 :

Q: Do you have any certification for this machine?

A: YES, We have CE ISO FCC ROHS, etc.Q: What is the warranty on the machine?

A:1 year for Auto PCB Depaneling machine.Q: How do you pack the machine?

A: We fix the machine on the plywood base with screws to ensure safe transportation.Q: What is a lifetime of machine blades?

A: About 6-12 months.Q: What is the material of blades?

A: Japan high-speed steel SKH-9Q: Can the blades be sharpened?

A: Yes, the Auto PCB Depaneling machine could be re-sharpened 2-3 times.Q: How do you offer overseas service?

A: We could send an engineer to do installation and training for clients if needs.Q: Can we see your machine in our country?

A: Yes, we would like to offer the contact details of our clients who are using our Auto PCB Depaneling machine.

Contact details:

Welcome to contact and get more information:

Email: wayne@smthelp.com

Skype:waynesmt@outlook.com

Whatsapp/WeChat: +86 15817498429