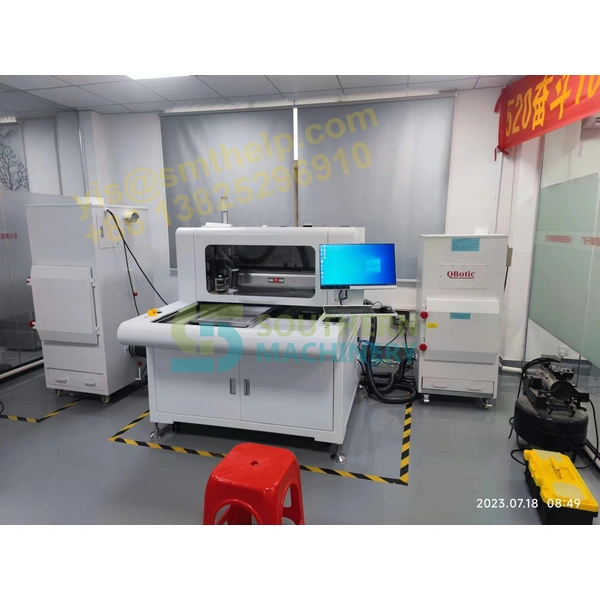

Contact: yis@smthelp.com Whatsapp: +8613825296910

Video: https://youtu.be/NAjTcjuL7-U

Desc:

1. When splitting with a milling cutter automatic splitter, the splitting stress is small, which is 1% of the hand splitting type and 0.1% of the punching type, which greatly reduces the hidden damage to the pcb board, which in turn allows The service life of the pcb board is improved.

2. The milling cutter automatic splitting machine can cut arcs, curves, straight lines and oblique lines. Compared with the aluminum substrate splitting machine, light strip splitting machine, and knife splitting machine, the milling cutter splitting machine has greater flexibility Wider applicability. As long as the board is divided, the cutting route must be programmed in advance according to the situation of the products to be cut.

3. The automatic splitting machine with milling cutter replaces manual breaking, PUSH or V-CUT splitting defects, which greatly improves the quality of pcbA board products and reduces the defective rate of pcbA boards. Because the quality of manual breaking is uncontrollable, the quality is prone to problems, and at the same time, the safety of the operator cannot be guaranteed. When the manual breaking is uneven, the pcb board is easily damaged, and the pcb electrical circuit and related parts , The destruction of the tin road, the shedding of components, the deformation of the pcb board, etc. lead to the shortening of the service life of the pcb board.

4. The milling cutter automatic board splitting machine uses a high-speed milling cutter for cutting, with high splitting accuracy, and the cross-section of the cut pcb board is smooth and burr-free, which is very suitable for customers with high product requirements.

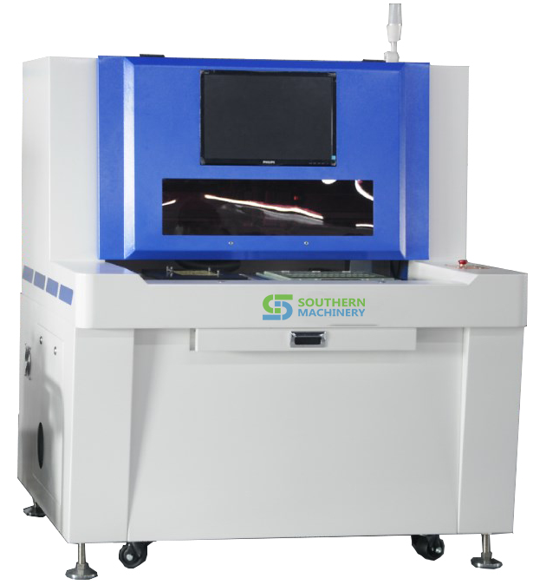

Features:

Daul-table uninterrupted working, with safety grating

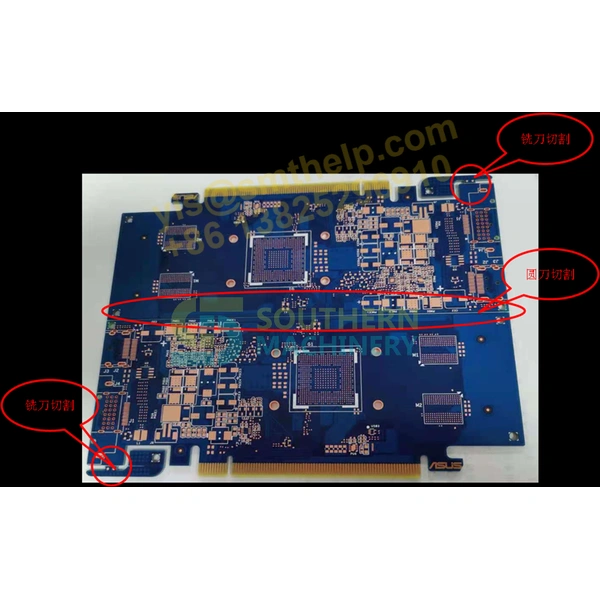

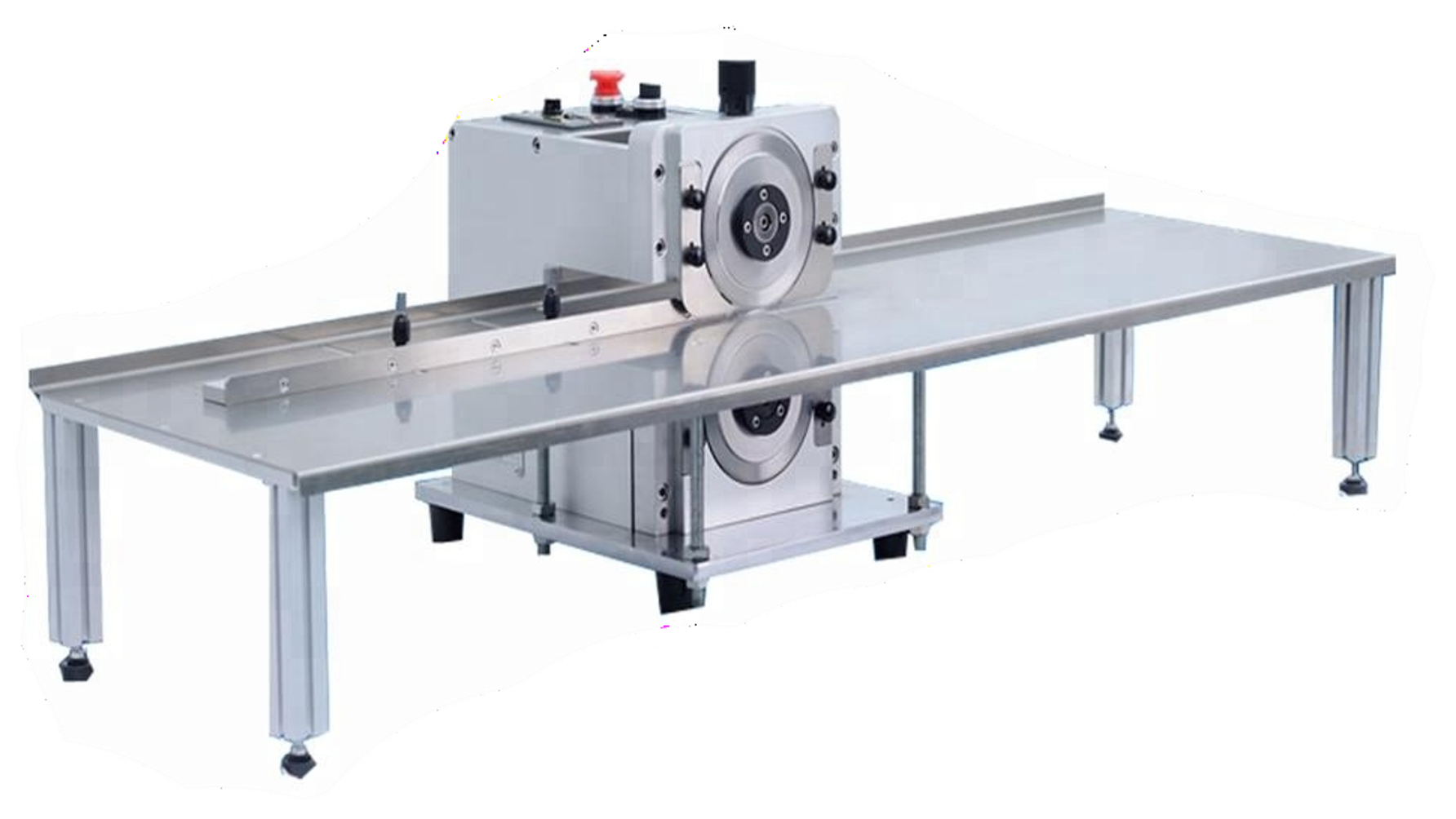

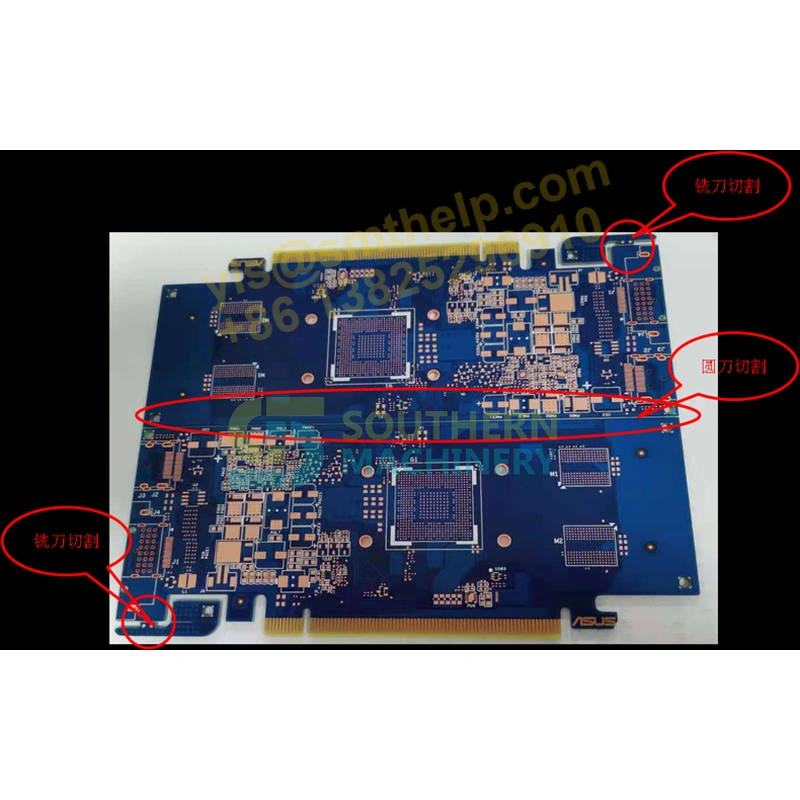

Circular Blade for V Groove

Milling Cutter for Stamp →Hole

Automatic cutter changing over and breaking detection

Accurate and fast positioning of the MARK point and cutting line

Faster and smarter programming

With lower/upper dust collector

Specifictions:

Effective cutting size 350*550MM

Cutting capacity Ability to cut straight lines, arcs, circles, L-shaped, U-shaped, stamp-hole models, and V-slot models Required items

Working area (machinable stroke) V groove, stamp hole, bridge and circle, etc.

Cutting PCB thickness range 0.3-3mm

Repeat positioning accuracy ± 0.01mm

Tool monitoring Automatic tool sinking, tool breaking and sliding tool detection

Cutting speed 5~100mm/s adjustable

Spindle speed Max 60000 rev/min

Work table Dual Table

Applicable milling cutter size 0.8~3.0MM

Computers and Operating Systems Industrial computer, Windows 7 or above

X, Y1, Y2, Z axis Panasonic A6 series servo drive

Power Separator/Dust collector AC220V 50/60HZ 1 HP/AC380V 3 HP

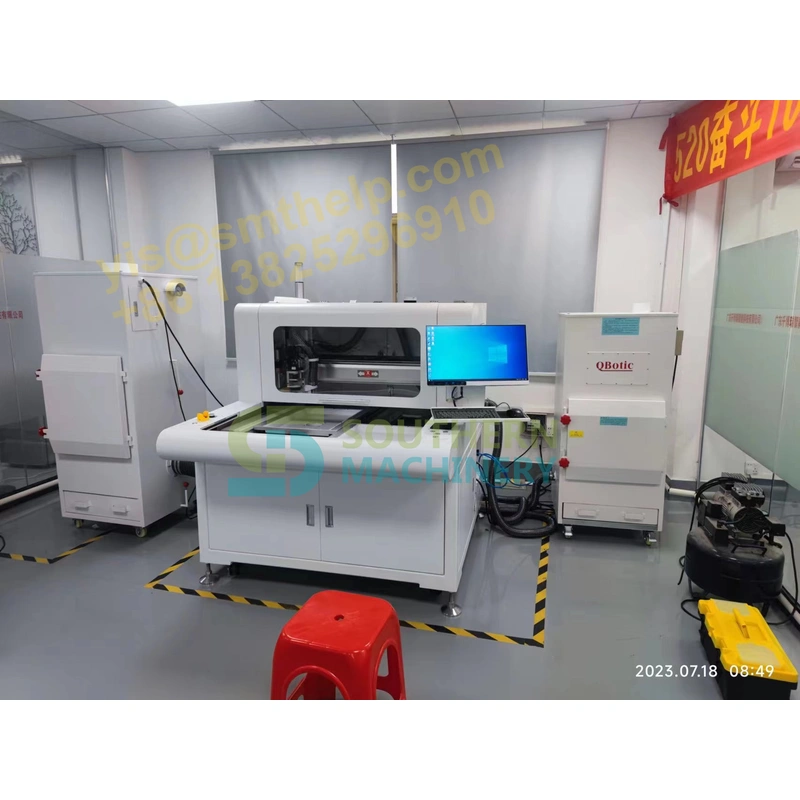

Separator Size/Weight 1180mm*1180mm*1350mm/800kg

Dust collector size/Weight 665mm*635mm*1610mm/155KG

Dust collection method bottom dust collection/top dust collection (optional)