[embeddoc url=”//hk03-1251009151.file.myqcloud.com/smthelp.com/desc/2015/12/S7000-Odd-form-Insertion-machine-Operation-Manual-1.pdf” download=”all”]

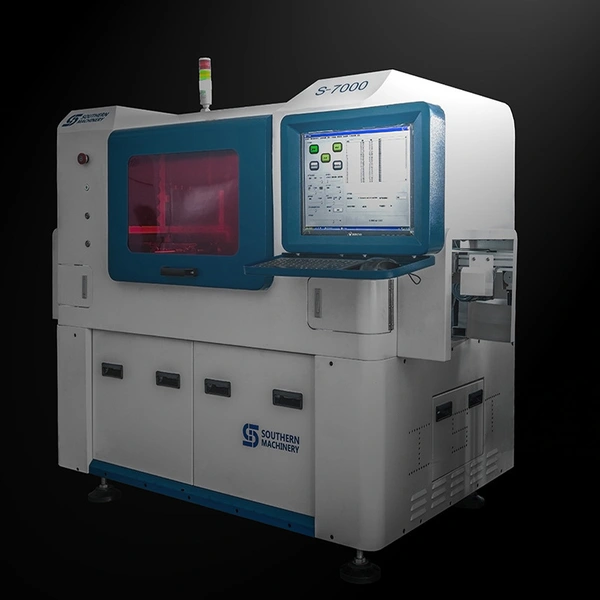

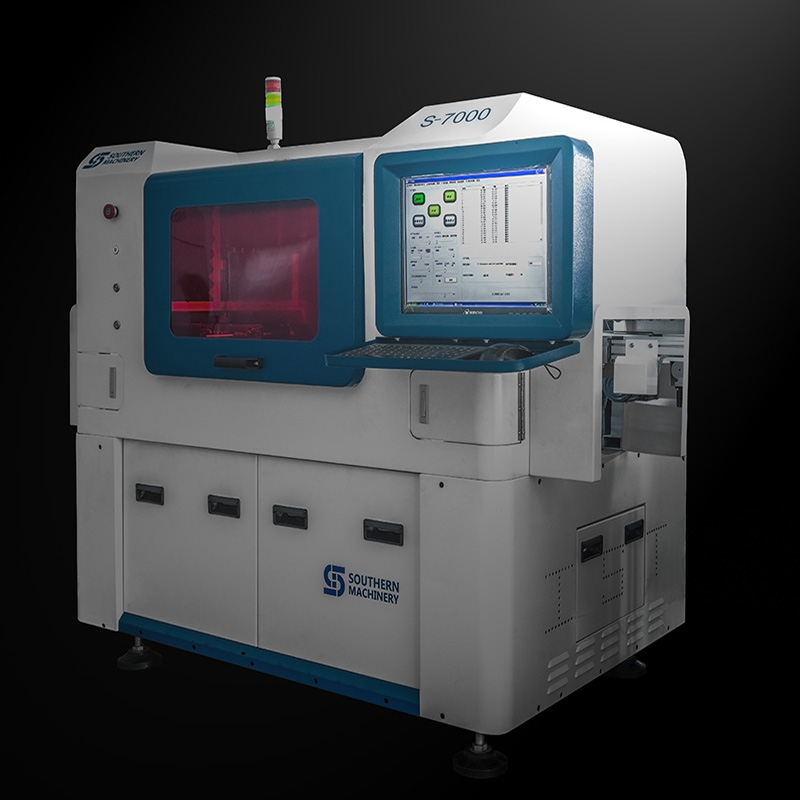

Product Description

Southern Machinery’s Odd Form Insertion Machine of S-7000 provides outgoing board quality levels of 500 ppm or better with high insertion speed, providing superior reliability and price-performance.

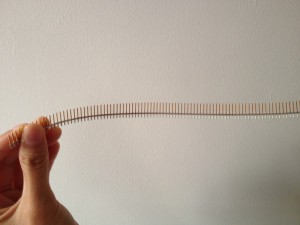

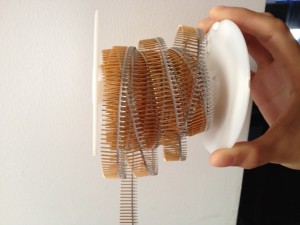

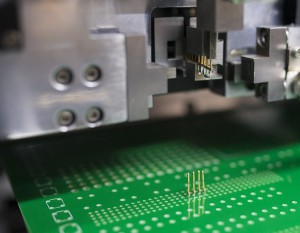

The equipment conveys rivets of various specifications (1.6 mm to 3.5 mm) sorted by the vibration plate to the clamp block, the insertion shaft accurately and quickly inserts rivets to holes on the PCB, and the base blooms rivets to various patterns and fastens them onto the PCB. The equipment can load and unload PCB automatically. It is equipped with one to four insertion shafts and can insert rivets of one to four models. One operator can operate several machines.

Based on Windows 2000, the simple-to-use, operator environment provides machine operation functionality, diagnostic support, management data, and a graphical product editor for easy pattern generation and maintenance.

Odd Form Definition

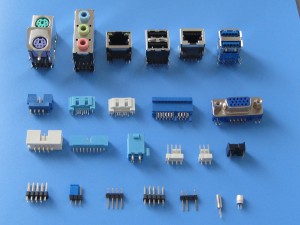

Odd Component:

Odd shape through-hole components that can not be automatically placed using standard through-hole insert machines due to the component’s height, shape or weight:

Trends Driving Odd-Form Automation:

- Drive to reduce defects

- Need to increase throughput

- Cost and availability of manual labor

– Availability of packaging

– Need for reduction in manufacturing costs

Market Challenges:

- Irregular packaging

- Conversion from hand assembly

- Competing in low-cost markets

- Lack of industry standards governing the assembly process

- Large and Heavy Components

- High force requirements

S7000 Odd-Form Solutions:

- Most flexible head available on the market

- Vision component inspection enables use for in Pin-in-Paste Applications

- Vision component inspection finds quality problems before insertion

- Data-driven programming and component database that bridges the gap between custom automation and Surface Mount Assembly Machines.

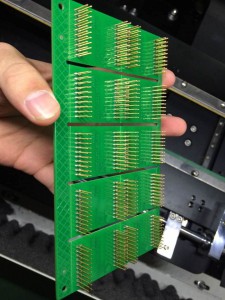

Bare PCB

Odd Form Components

Save