| Specifications | |

| PCB Size | Max.50~250mm |

| Conveyor height | 750±50mm |

| Conveyor speed | 0~1.8M/Min |

| Conveyor Angle | 3~7º (adjustable) |

| Conveyor direction | L->R |

| Component heigh | Max.100mm |

| Pre-heating zone | 600mm |

| Solder pot wave | 2 |

| Pre-heating power | 3kw |

| Pre-heating zone temp | room temperature–250°C |

| Cooling zone | 1Fan cooling |

| Solder pot power | 6kw |

| Solder pot capacity | Approx.200KG |

| Solder pot temperature | room temperature–300°C±1-2℃ |

| Control method | P.I.D+SSR |

| System Control | PLC + Touch Screen Control |

| Flux capacity | Max5﹒2L |

| Spray Fluxer | ST-6 Spray |

| Power Supply | 3P 380V AC |

| Total Power | max.9kw |

| Normal working power | Approx.1.5kw |

| Air Pressure | 4~7KG/CM2 |

| Overall Dimensions | L2100×W1200×H1400MM |

| Machine Weight | Approx.400kg |

Preparation before operation

1)Check the electric box has loose line and short circuit conditions or not;

2)check the transmission part if there is any Unidentified thing stuck;

3)check the preheating box have flammable objects and debris or not;

4)check the air pressure have 4 to 7 kg/cm or not

5)check whether the power supply three phase five wire, ground wire of resistance under 10R;

6)check whether the spray transverse cylinder flexible;

7) check the flux box if there is flux or not;

8)check whether the spray filter through content;

B The machine hardware installation and instructions

Install import board Conveyor

Take the import board conveyor to install docking, screw can be adjusted up and down the balance.

Note: 1.Conveyor guide high and low level adjustment

2.Conveyor guide vertical level adjustment

3.Conveyor guide right and left adjustment

Must let import conveyor chain plane into a straight line with claw.

Install the oil-water separator

a.Oil-water separator is installed on the side of board import hole where has a small hole (The above has two cross screws )

b.Plug in pipe ,installation is completed

Molten tin stove installation

a, the tin stove frame is installed in the position of tin stove in and out .

b.The tin should be distributed on the sides and bottom of the tin stove.(In order to avoid empty tin stove burning lead to deformation )

c.Open a tin furnace for heating temperature

d.In the process of heating, when tin melting on both sides of the tin stove,must continue to add tin. Until it is full .

e.Tin surface should be the plane in 5 mm different with tin stove . As the best state.

Following figure

Note: 1.The first wave control speeder

2.The second wave control speeder

3.Chain height adjustment

Note: 1.Adjust the size of air demand of rosin spraying

2.Adjust the size of air demand of rosin spraying moving orbit

Press the control switch on the operation panel

| Timer | Timing Switch |

| Preheating | Preheating Setting |

| Solder Machine | Tin Stove Tempreature Setting |

| Start | Power Switch |

| Lighting | Lamp Siwtch |

| Velocity | Chain Speed |

Monitoring menu: boot monitor will show as below

Touch screen display and flashing automatically ;

According to company name to the main menu. Any touch screen to enter the next menu.

This grapics for operating

a:In this picture is able to transport, spray, wave, washing, tin stove,manual/

automatically control one by one.

b:Tin stove is automatically start when turn on PC

c.Production counter starts counting from the first piece of PCB.

d:Transportation speed display 。”U” type optical eye not shown without

detection.(” U “light eyes in export of equipment )

e:”Settings”button to enter the next menu.

This menu is the main menu of setting spray distance, wave distance, peak time.

a: Spraying distance, setting value refers to the distance from light eyes into the sprayer.

b:wave distance, setting value refers to the distance from light eyes into the tin stove.

c:wave time, setting value refers to the automatic state the time of the wave crest.

(note: the value set are analog value, not as the actual distance and time.)

In the control panel of preheating and tin stove temperature control table

a: SV : Set value,

b: PV : easurements value.

c: OUT for SSR output signals

d: AT : PID automatic calculation indicator

e: ALM1 : Alarm 1 light

f: ALM2 : Alarm 2 lights

g: SET keys function keys.

h: Another three arrow button is used to set value.

Maintenence

1), Check whether the transmission has lubrication and smooth;

2), Check the transmission system fixed position whether there is loose;

3), Check whether the chain claw has a deformed shape;

4), Check whether the preheating box with debris, dust, and the stagnational flux ,clean them up;

5), Check the filter and remove flux cover and clean residue excess;

6), Check the sprayer spray atomization system is uniform or not, transverse cylinder smooth or not;

7), Check the tin oxide black powder, slag is too much or not;

8), Check whether the plane wave soldering tin is stable, thoroughly clean again per 400h.

Attention

1), Never put flux in a preheated box and tin stove

2), Never will drip flux on machinery and equipment with high temperature and electric box;

3), Absolutely can’t unlimited heating when without adding tin in tin stove;

4), Grounding line must be reliable;

5), Tin stove temperature optimal setting temperature to 260 ± 5 degrees;

6),The best transmission speed : 0.8-1.3 m/min.

7),Best preheating temperature, PCB welding side temperature :100±10 degrees.

<br /> &lt;br /&gt; &amp;lt;br /&amp;gt; &amp;amp;lt;br /&amp;amp;gt; &amp;amp;amp;lt;br /&amp;amp;amp;gt; &amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;gt;&amp;amp;amp;lt;br /&amp;amp;amp;gt;&amp;amp;lt;br /&amp;amp;gt;&amp;lt;br /&amp;gt;&lt;br /&gt;<br />

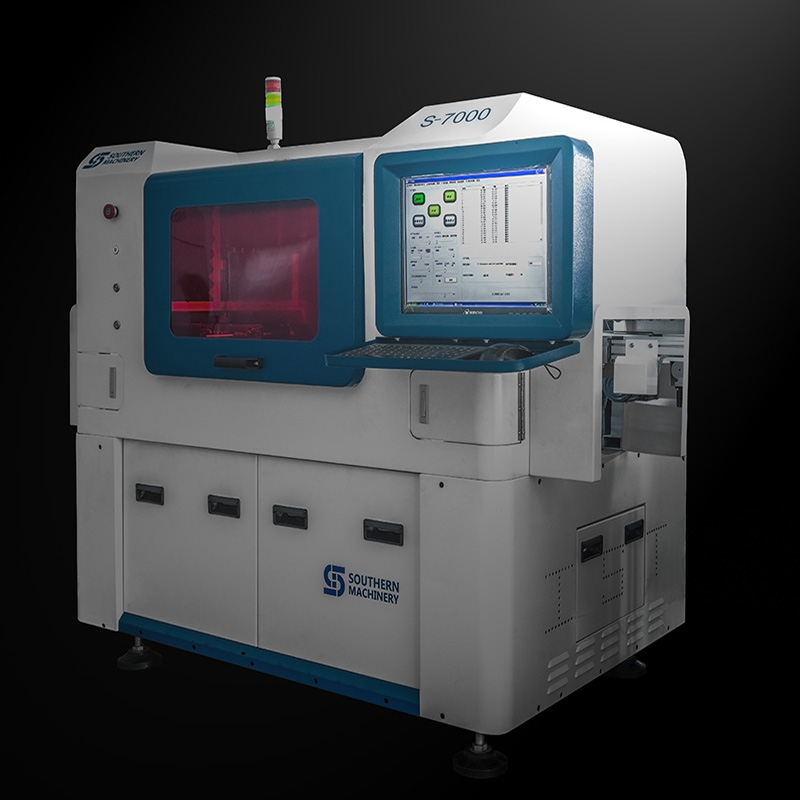

Improving PCBA wave soldering Quality from Shenzhen Southern Machinery Sales And Service Co., Ltd

<br /> &lt;br /&gt; &amp;lt;br /&amp;gt; &amp;amp;lt;br /&amp;amp;gt; &amp;amp;amp;lt;br /&amp;amp;amp;gt; &amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt; &amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;amp;gt;&amp;amp;amp;amp;lt;br /&amp;amp;amp;amp;gt;&amp;amp;amp;lt;br /&amp;amp;amp;gt;&amp;amp;lt;br /&amp;amp;gt;&amp;lt;br /&amp;gt;&lt;br /&gt;<br />

Improving PCBA wave soldering Quality from Shenzhen Southern Machinery Sales And Service Co., Ltd