If you are looking for a reliable and efficient nozzle cleaning machine for your electronic products manufacturing factory, you should check out the S-6200 Nozzle Cleaning Machine from SMTHELP. It is a fully automatic machine that can clean your nozzles quickly, thoroughly and safely, using water or solvent. It can remove any solder paste residue, dust and dirt that may affect the quality and performance of your nozzles and PCBAs. It can also dry your nozzles with hot air circulation and moisture detection. It is suitable for different types of nozzles, such as Fuji, Panasonic, Yamaha, Samsung, Juki and more.

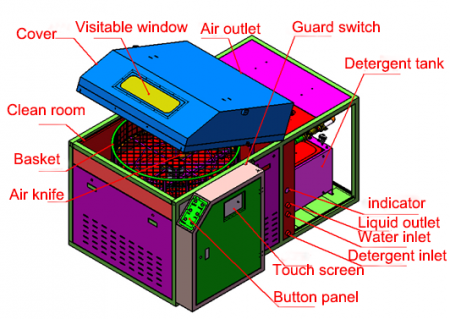

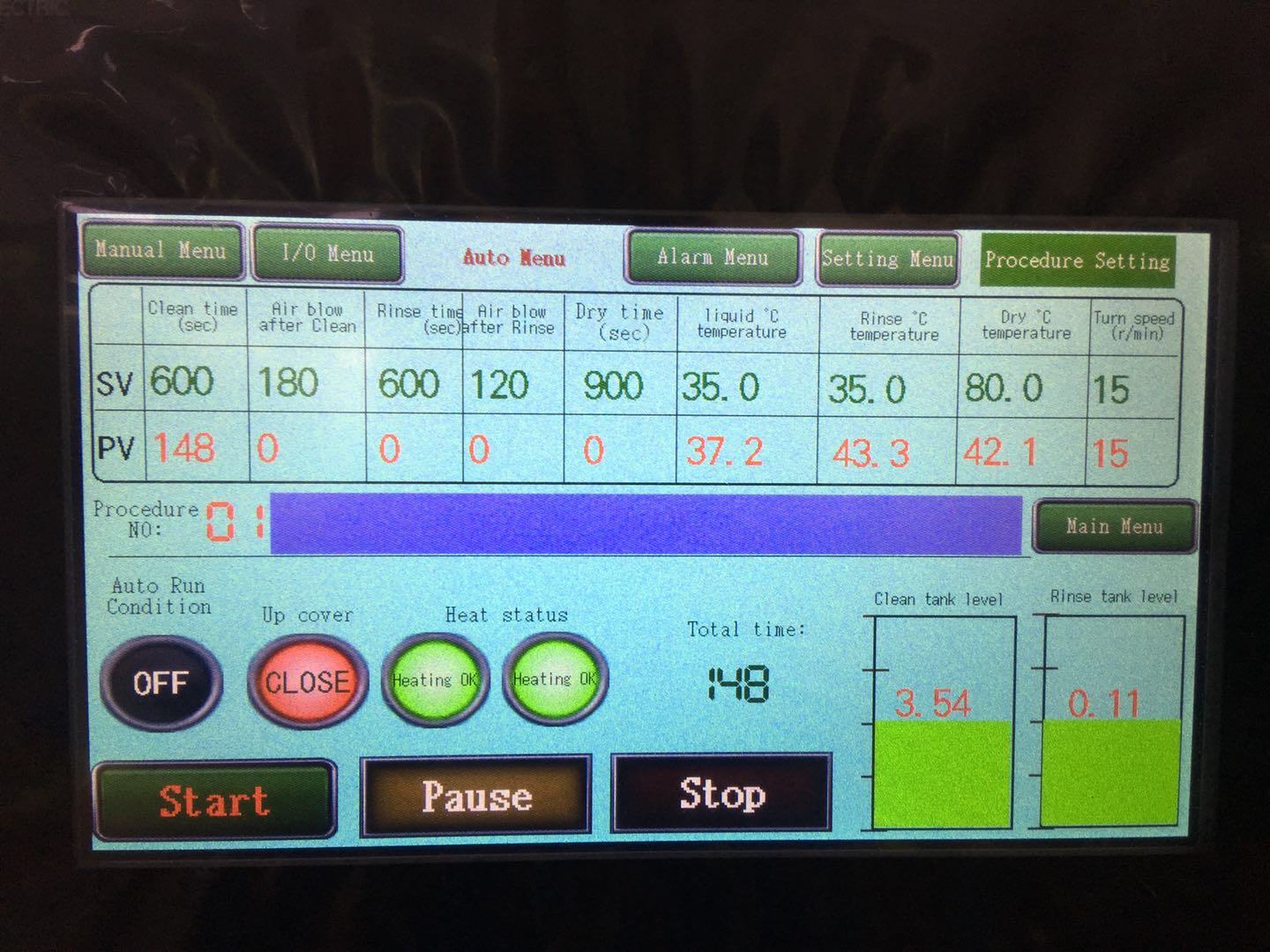

The S-6200 Nozzle Cleaning Machine has many features and advantages that make it the best choice for your SMT process. It has a PLC control and touch screen operation that makes it easy to use and monitor. It has a stainless steel structure that is corrosion-resistant and anti-static. It has an adjustable cleaning pressure, time and temperature that can meet your specific needs. It has a high-efficiency ultrasonic system that can generate multiple frequencies and power levels to clean your nozzles. It has an environmentally friendly cleaning solution that has low consumption and recycling function. It has safety features such as emergency stop, door lock, liquid level alarm and overheat protection.

By using the S-6200 Nozzle Cleaning Machine, you can enjoy many benefits for your SMT process. You can improve the quality and consistency of your nozzle placement and solder paste application by removing any unwanted materials that may cause clogging, wear and tear, and contamination. You can save time and labor costs by eliminating manual cleaning and drying. You can extend the lifespan and performance of your nozzles and feeders. You can enhance your environmental compliance and safety by reducing the impact of cleaning solution on the environment and workers.

The S-6200 Nozzle Cleaning Machine is the perfect solution for your electronic products manufacturing factory. Whether you are Foxconn, Flex, Jabil, Signify or any other global leader in SMT market, you will find this machine to be a valuable asset for your SMT process. Contact us today to get a quote and a free demo. You will not regret it.

Overview:

SCM-24 using the hydrodynamic water fragmentation,producing very fine water mist,with the speed of sound (V = 360m/s) to form a strong momentum jet to the nozzle, nozzle for cleaning at the top of the formation of a continuous field,crushing the internal surface of the dirt (the nozzle will not be damaged because of its independent device),during the cleaning process the used cleaning water (deionized water or distilled water) automatic direct emissions.

Functions:

1. Thoroughly clean the dirt on nozzles which ultrasonic cleaner can not clean. 2. Strong clean power for nozzles ,even the smallest nozzle hole. 3. Very good cleaning effectiveness, extend lifespan of the nozzles. 4. No damage to the coating layer of the nozzle and its reflector panel. 5. Only use DI water or distilled water . 6. Auto clean and dry. 7. Easy operation. 8. Right for all kind of mounter nozzles .

Multifunctional Humanized Functions:

1. With TP operation interface, PLC programme control;easy operation. 2. Pneumatic parts are Japan SMC ,this gurantee the stability and efficiency of the machine. 3. Main parts of the machine, like cleaning room; water tank; nozzle and jet head rotation mechanism and installation base are made of SUS304,special parts used SUS 316 from Japan,to ensure that the machine will not rust due to the water,to avoid other security risks and get longer life;

Cleaning Principle:

Withit special mechanical design,SCM-24 using the hydrodynamic water fragmentation,producing very fine water mist,with the speed of sound (V = 360m/s) to form a strong momentum jet to the nozzle, nozzle for cleaning at the top of the formation of a continuous field,crushing the internal surface of the dirt (the nozzle will not be damaged because of its independent device),during the cleaning process the used cleaning water (deionized water or distilled water) automatic direct emissions.

Specification

| ITEM | SME-24 SPEC |

| Air supply | 0.5~0.7Mpa |

| Power supply | AC220V,1A |

| Clean liquid | Purified water or DI water |

| Clean time | 3~6min |

| Dry time | 1~3min |

| Spray pressure | ≤0.55Mpa |

| Clean liquid consumption | ≤150cc/Hour |

| Nozzle range | Min01005~Max hole diameter¢2.0mm |

| Jig spec | 24holes |

| Machine size | L665*W555*H475(mm) |

| Machine weight | 30KG |

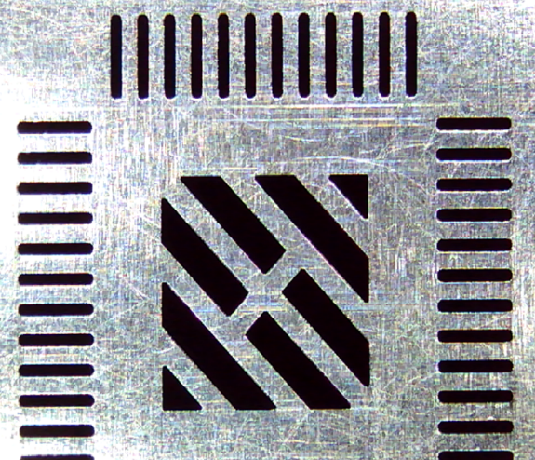

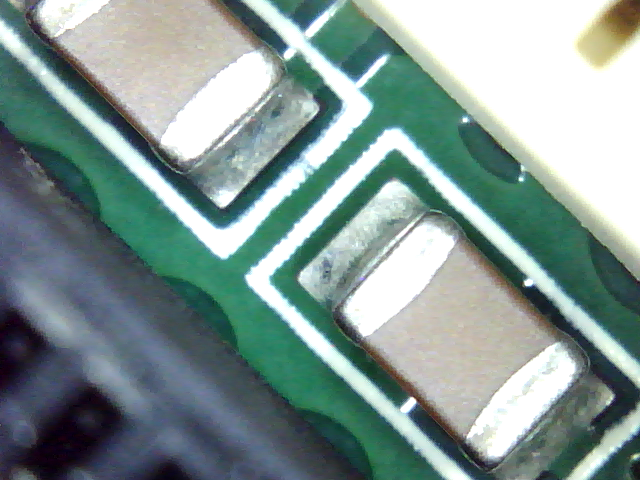

SCM24 cleaning result compare with Ultrasonic cleaner

SCM24 cleaning result compare with Ultrasonic cleaner

SCM24 cleaning result compare with Ultrasonic cleaner(2)

SCM24 cleaning result compare with Ultrasonic cleaner(2)

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist