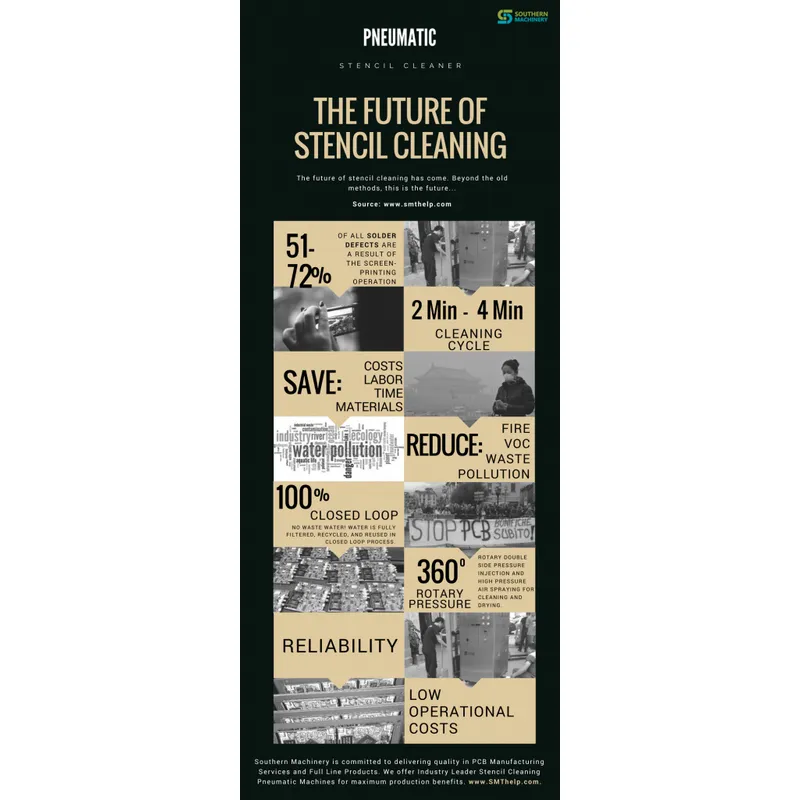

Overview:

S-168 series automatic PCBA washing machine; it is an online automatic PCBA board special cleaning machine, suitable for traditional washing water without manual contact with cleaning agent. This equipment uses PCB board transmission technology and brush cleaning technology. Combined, multi-channel brushing in all directions of front, back, left and right, cleaning without dead angle, to ensure that the PCBA board meets the cleanliness requirements. Suitable for cleaning single-sided PCBA board soldering surfaces without wetting the front components.

[pdf-embedder url=”//hk03-1251009151.file.myqcloud.com/smthelp.com/desc/2019/03/PCB-CLEARING-MACHINER-(SPT250).pdf” title=”PCB CLEARING MACHINER (SPT250)”]

Main features of this machine:

This machine has a unique body structure, stable performance and the highest cleaning effect in the industry;

Dedicated to the cleaning of tin beads, flux traces and scratches;

Imported brown hair brush, anti-static brush, will not generate static electricity, will not harm the PCB board.;

Applicable to PCB boards with a board edge (minimum distance of 1.5mm), width 10-500mm, thickened shrapnel claws to ensure that the PCB board will not be displaced during transportation;

Automatic coating system for cleaning agent: ensure that the welding surface of the PCB can be evenly coated with the washing water without affecting the surface of other parts;

Disc brush + two rollers: ensure that the PCB is cleaned in all directions, no dead angle;

Cleaning brush height, speed (stepless speed change) can be adjusted to meet different levels of cleaning needs;

The waste generated by the work is automatically collected in the filter box at the lower part of the machine for easy cleaning;

Using high-quality electronic speed-regulating motor drive, the motor speed is steplessly adjustable and durable.

Power supply of 220 volts. Easy to use;

Adopt brand electrical appliances and control systems to ensure the reliability and stability of the control system;

● Modular control.

Machine technical parameters

S-168 MODEL

| Technical parameters (can be customized) | |

| PCB Max size: | 300mm(W) x 300mm(L) |

| Dimensions: | L1750*W770*H980±2mm |

| Coating drum size | L320mm |

| Disc brush size | φ 300 |

| Spindle speed | 0-500 R/min(Continuously variable speed) |

| power supply | 220V 50HZ |

| power | 0.5(KW) |

| Transmission speed | 0.05~1.8m/min(Continuously variable speed) |

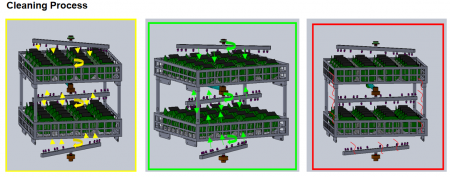

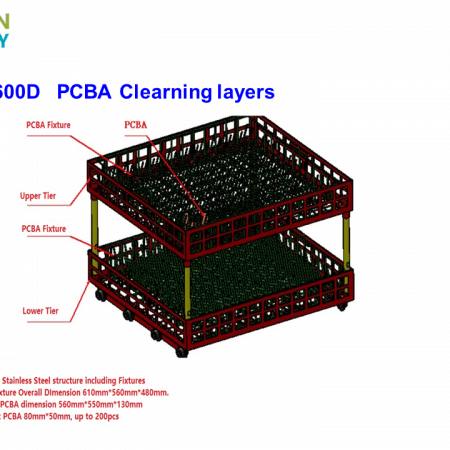

Cleaning process

| PCB in |

| Disc brushing |

| Disc brushing

|

| 2st brush cleaning

|

| 1st brush cleaning |

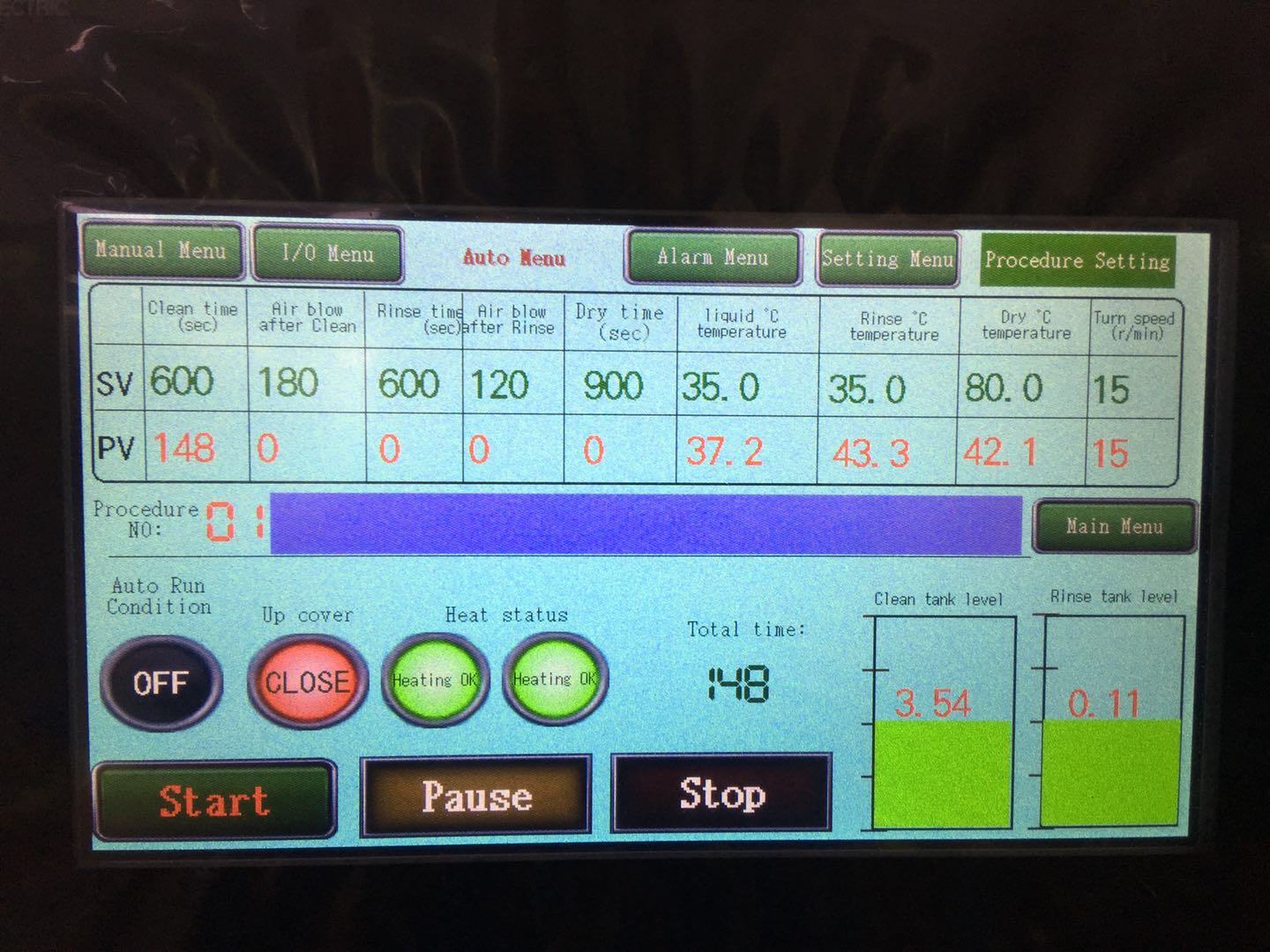

Process parameters

| item | Process name | Cleaning medium | Cleaning Time | cleaning method | Cleaning box | Remarks |

| 1 | 1st cleaning | detergent | on demand | Roller brush (abrasive) | Special SUS | |

| 3 | 2st cleaning | — | on demand | Disc brush (brown hair) | Special SUS | |

| 4 | 3st cleaning | detergent | on demand | Roller brush (abrasive) | Special SUS | |

| 5 | 4st cleaning | — | on demand | Disc brush (brown hair) | Special SUS |

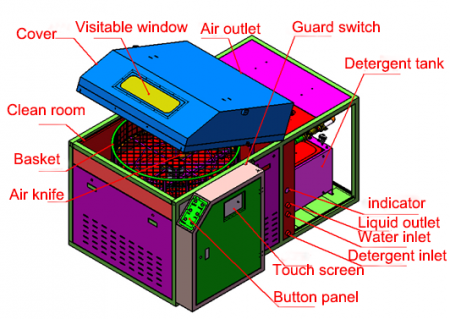

Cleaning structure and function

Equipment structure: including feeding connection mechanism, transportation mechanism, brush cleaning system, circulation filtration system, air drying system, PLC program controller, and other automatic control systems. Each system is designed as a separate module, which is easy to operate and easy to maintain.

The whole machine is automatically controlled by PLC, with complete functions, and has both automatic and manual operation modes. The automatic mode is (economy mode), which can greatly reduce the consumption of cleaning agents and electric energy;

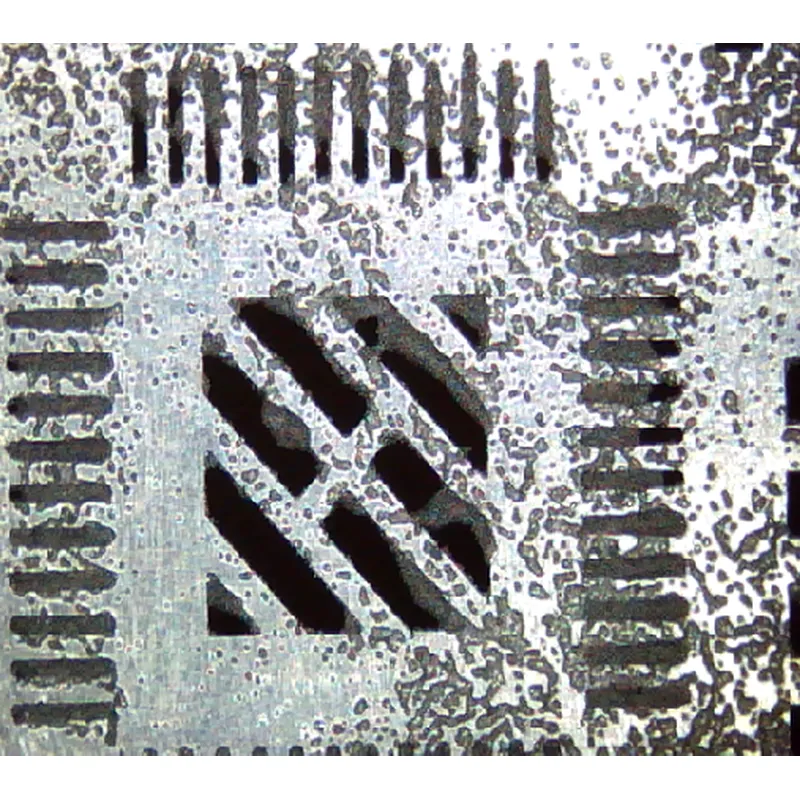

The disc brush and the roller brush simultaneously clean the bottom of the PCB board in front, back, left and right, and clean without dead angle;

Cleaning module Equipped with a fully enclosed three-stage automatic circulation filtration system, the filter is continuously filtered and cleaned, so that the cleaning liquid is always maintained at a high level of active state, and the cleaning liquid is recycled;

The cleaning liquid tank is equipped with low liquid level alarm and over limit liquid level alarm function;

Air drying device, which acts on the cleaned PCB board by a fan to make the surface dry quickly;

The wet cleaning module and the dry cleaning module are independent of the motor, and the speed can be adjusted independently. The height can be adjusted independently. Suitable for all kinds of PCB

Board cleaning process;

One-stage, second-level brush wet cleaning module: One-stage, second-level brush cleaning module, including two sets of abrasive brushes, two sets of spray pipes, reverse-rotating to brush the PCB, and the cleaning liquid is returned to the cycle system.

Level 1 dry cleaning module: Contains a set of disc brown brush, which is used to clean the PCBA board in reverse rotation.

Secondary wet cleaning module: It contains a set of roller abrasive brushes, a set of spray pipes, and the PCBA plate is brushed in reverse rotation, and the cleaning liquid is returned to the circulation system.

Secondary dry cleaning module: It contains a set of disc brown brush and cleans the PCBA board in forward rotation.

Liquid level control device:

When the liquid level in the cleaning tank drops to the low level warning line, the level controller will send an alarm signal to prompt manual rehydration.

Feed structure and transport transport system:

In-line device synchronized with the transport rail, easy to feed

The whole process of transportation is visualized, and the operation of the PCB inside the machine can be clearly observed.

Circulating filtration system:

Cleaning tank → liquid storage tank → primary filtration → sedimentation tank → liquid storage tank → circulation pump → return to the cleaning tank for repeated use.

Control system:

Control mode: divided into “manual operation / intelligent economic operation”

Manual operation mode: each system function can be completed manually one by one.

Intelligent economic operation mode: When there is no PCBA board in the machine, the system will automatically judge. At this time, the brush is cleaned and the pump enters the stop state. The cleaning fluid circulation system enters a fully enclosed state.

9 . Machine installation

Equipment installation reserved space: three manual stations on the unilateral side of the pipeline

Power supply requirements:

Power supply voltage: AC 220V/110V

Voltage fluctuation range: 220V ± 10%

Frequency and fluctuation range: 50Hz ± 1Hz10.

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist