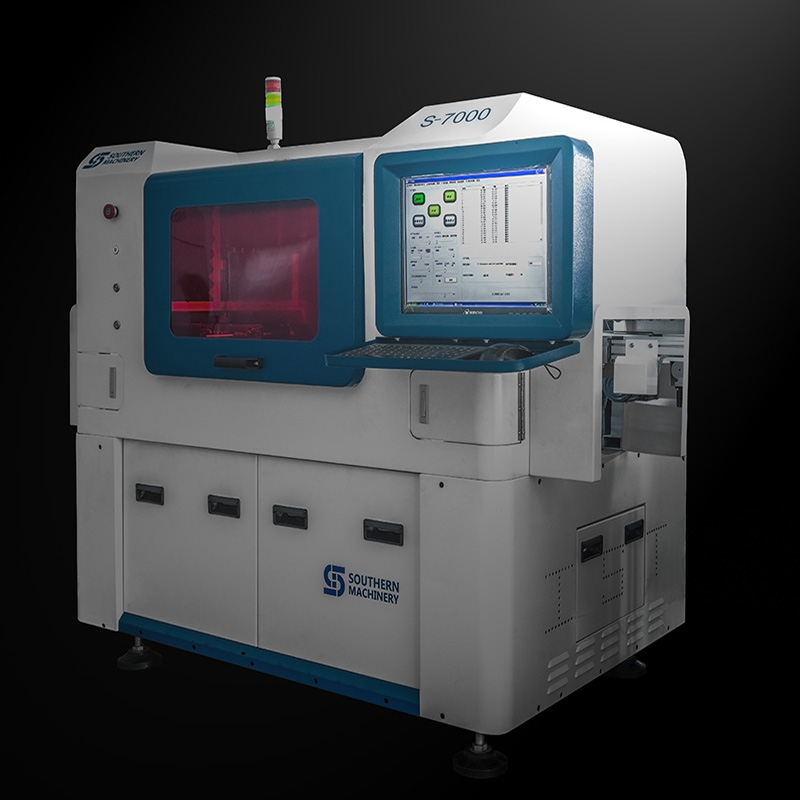

Perfect Solution for EMS PCB assembly Automatic Insertion Solutions for Axial Components & Jumper Wire—S4000 Axial Auto Insertion Machine

Machine Overview:

Up to 22,000 cph

Off-line/In-line operation availability

Using imported precision ball-screw & AC Servo system, positioning accuracy <0.001mm

Vision system for positioning and insertion alignment

Insertion angle in 0º, 90º, 180º, 270º

Integral forming cast iron machine frame

Component lead span from 5-22mm

Can handle the axial components and jumper Simultaneously

Capable of jumper insertion independently

Second level component centering mechanism(Option)

USB port for data transfer & Excel format compatible

Clinch lead angle is adjustable in a range (0°- 45°). Clinch lead length is adjustable from 1.28mm (0.050") to 1.80mm (0.071") and is measured from the center of the insertion hole to the end of the lead.

Significant feature:

Make EMS PCB assembly easier,especially Axial Components+Jumper Wire at the same time.

•Can be automatically inserted into the different kinds of braid PCB components, all kinds of electronic components and jumper wire, etc., with poor detection and plugin a leakage detection

•Can direct the orchestration of the tubular again jump line without directly inserted into the PCB, can save a third of the jump line

•Both can separate jumpers, and can separate horizontal electronic components, can also jump line and the horizontal components mixed interpolation.

•A machine, only need one operator, to complete the production capacity of forty people manual plug-in.

•Effective protection system program, to avoid plug-in USB data transmission errors and damage to the PCB

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist