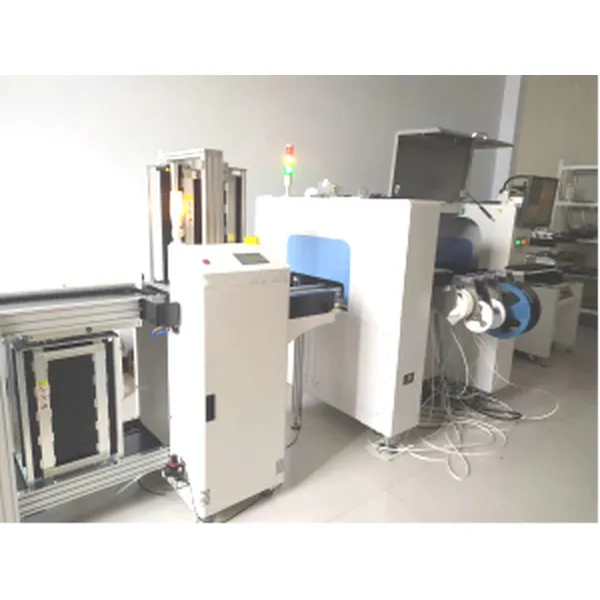

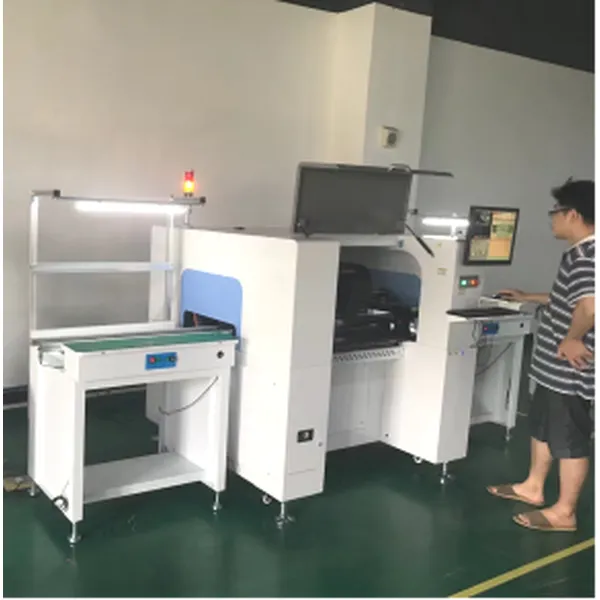

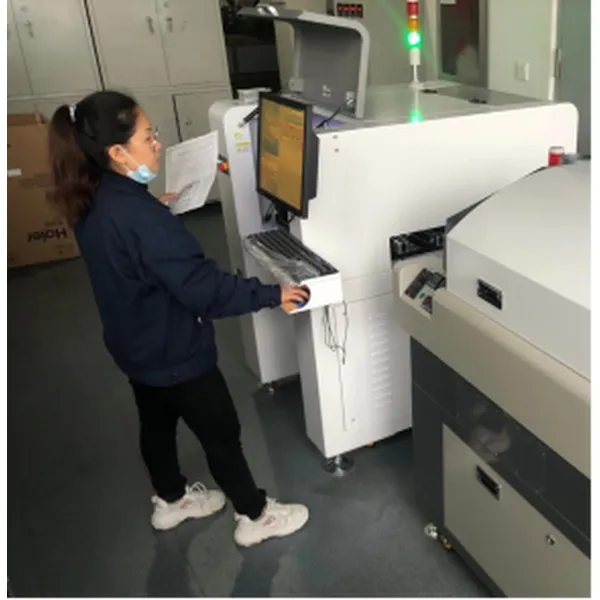

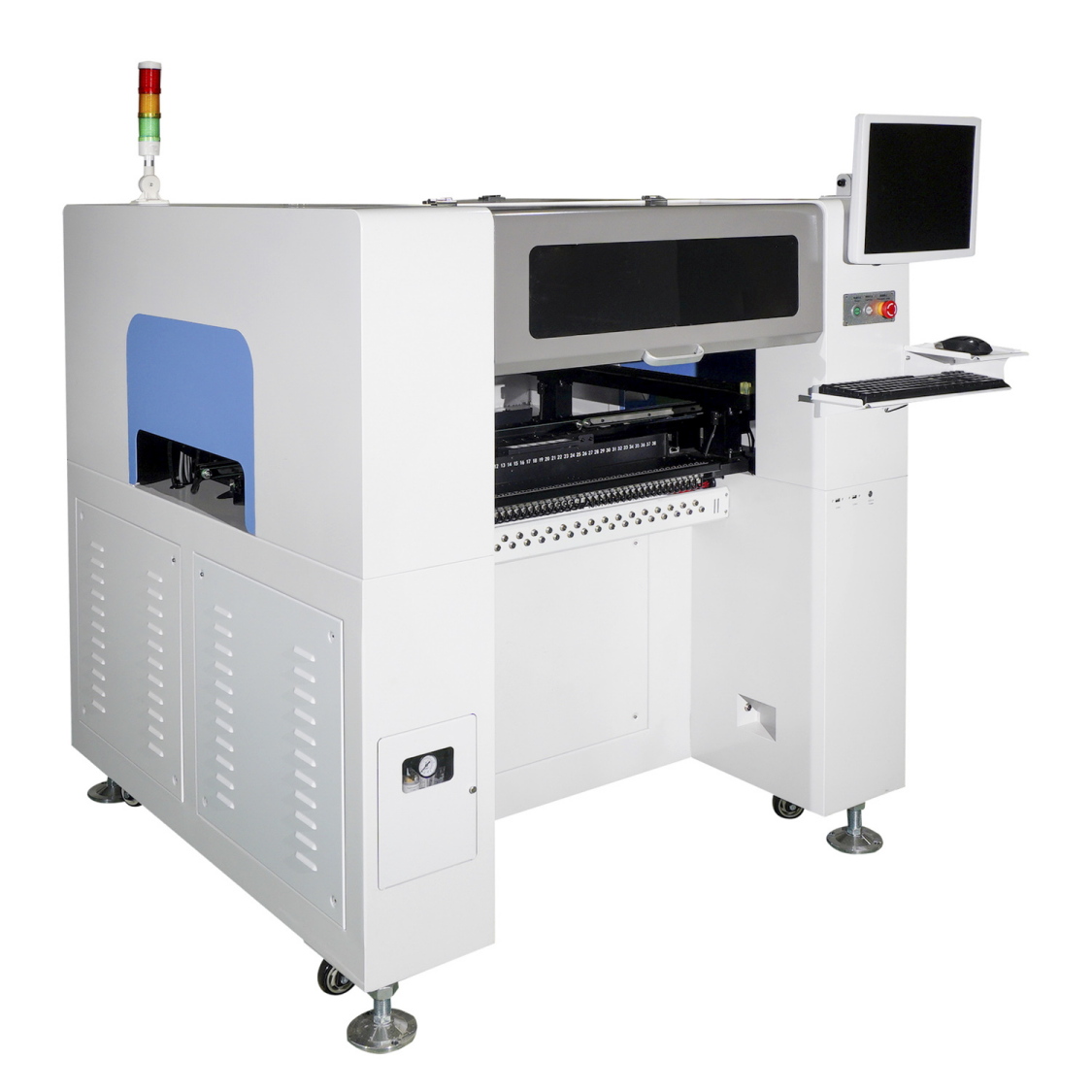

Machine Features

FAQ about pick and place machine:

1. What is a pick and place machine?

A pick and place machine is an automated system that picks up components or objects and places them precisely onto a target location.

2. How does a pick and place machine work?

A pick and place machine uses a robotic arm fitted with a specialized end-of-arm tooling to grasp components from a source location and place them accurately onto a target location. Precision motion control and computer vision are used to accurately control the robotic arm.

3. What is the end-of-arm tooling?

The end-of-arm tooling refers to the customized gripper or vacuum tool attached to the end of the robotic arm to grasp and hold components. It is designed specifically for the components that need to be handled.

4. How fast can a pick and place machine operate?

Modern high-speed pick and place machines can place tens of thousands of components per hour with a precision of 0.2mm or better. The speed depends on the complexity of the components and process.

5. What types of components can a pick and place machine handle?

Pick and place machines are used to accurately handle a wide range of components from small electronic chips, connectors and capacitors to large automotive parts. They are used extensively in electronics assembly, automotive manufacturing, medical device assembly, etc.

6. How much does an average pick and place machine cost?

The cost of a pick and place machine can range from $20,000 up to $500,000 or more depending on its speed, precision, payload, and complexity. High-end machines used for advanced manufacturing can cost $2 million or higher.

7. What is the maintenance required for a pick and place machine?

Regular maintenance like lubricating moving parts and tightening connections may be required daily or weekly. Software and firmware may also need to be updated periodically. Larger maintenance tasks like replacing worn parts may be required every few months. An annual maintenance contract with the equipment vendor is common.

8. What is the lifespan of a typical pick and place machine?

A well-maintained modern pick and place machine can typically operate for 7-10 years. However, technological improvements mean that newer models with better capabilities are frequently introduced. Many manufacturers provide upgrade options to extend the lifespan.

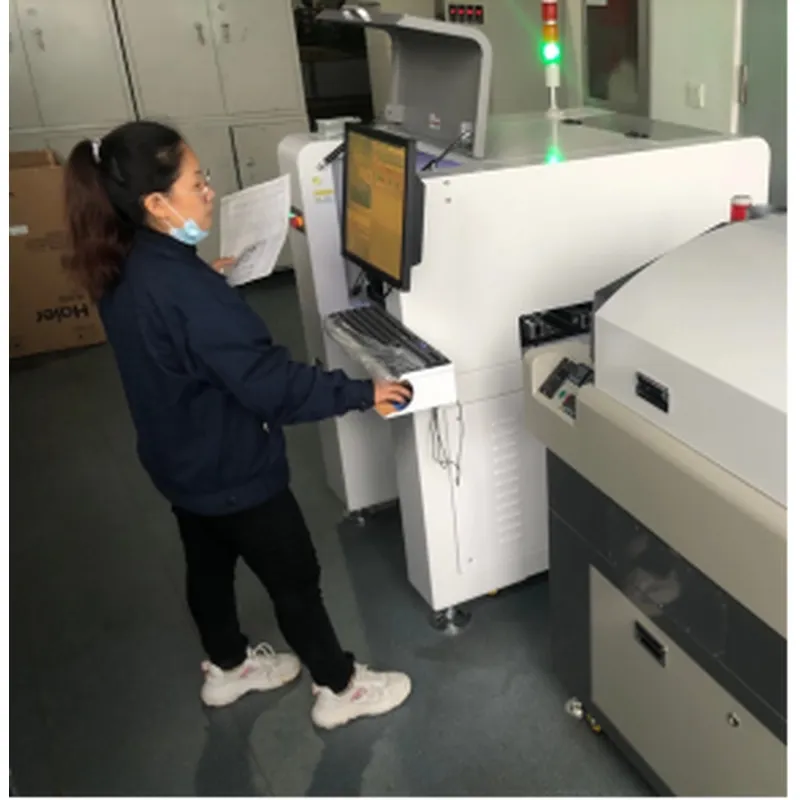

9. Are pick and place machines easy to program?

Most pick and place machines are programmable, allowing the user to specify the precise sequence of pick and place operations. While basic programming is relatively straightforward, developing optimal and synchronized motion sequences can take substantial time and expertise. Many manufacturers provide software tools to assist with programming.

10. Are pick and place machines in high demand?

Yes, pick and place machines are a crucial piece of automation equipment used extensively in modern advanced manufacturing. Demand for faster, more precise and higher-payload machines continues to grow to support emerging technologies like advanced electronics, electric vehicles, medical devices, and smart production lines.

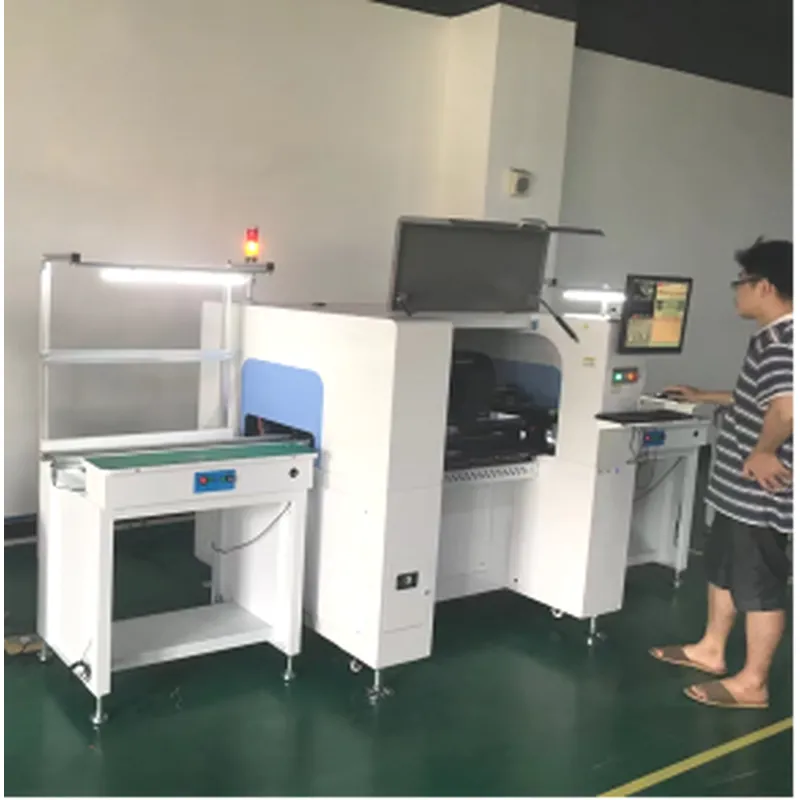

Our Advantages

1. Professional automated electronic manufacturing equipment for more than 20 years.

2. Own brand, own patents, customized design and solutions, provide after-sales service such as installation training worldwide.

3. Quick respond, 1 day parts delivery, 1 month machine lead-time.

4. Competetive price, the same performance price is lower than half of foreign brands.

Contact

WhatsApp/Skype:+8615622888481

Email:jack@smthelp.com