Technical Parameters

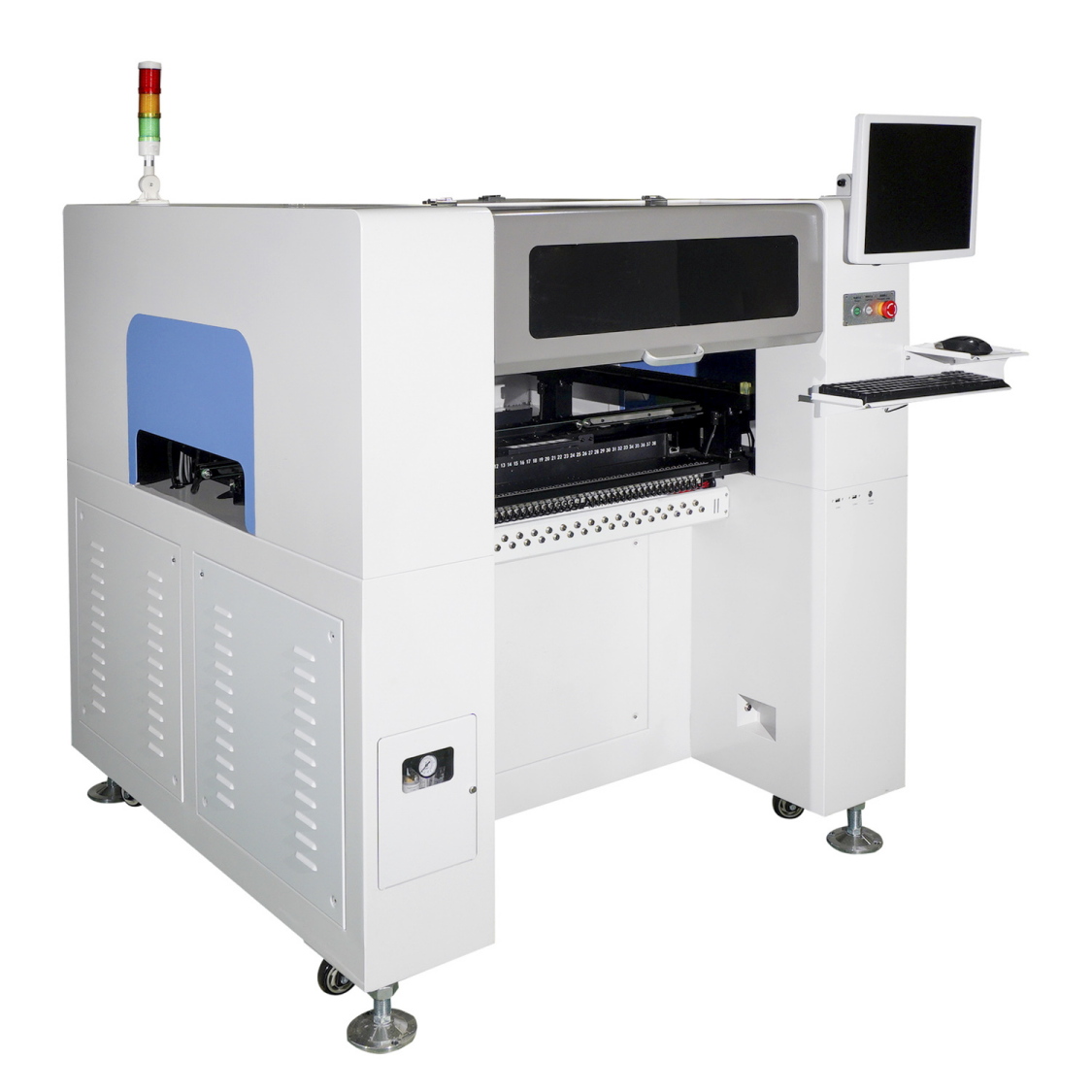

Model: S-530SV

Alignment: Flying Vision Alignment System

Number of Spindles: 8 Spindles x 1 Gantry

Rated Placement Speed/ Vision Alignment: LED 2835/45,000 CPH (Optimum)

Placement Accuracy: ±0.05mm (Based on the standard chips)

Mechanical Precision: ±0.02mm

Component Range: Vision Alignment-0603(inch)~5050~7474(mm), high-power LED, IC<10mm; Max Height-H=10mm (can handle max. 16mm without vision

alignment)

Board Dimension(mm): Maximum 1,500(L) x 400(W)

Board Handling Method: Magnetic Fixture Worktable

Tape Feeder: Feeder Type-Electric Feeder; Feeder Capacity-20 (12mm); Optional-8mm, 12mm, 16mm, 24mm

Utility: Power AC 220V/240V 50/60Hz, Single phase, Max 2.8KW; Air Supply-Built-in Vacuum Pump

Mass: Approx. 1560kg

External Dimension(mm) 2,000(L) x 1,250(D) x 1,400(H)

Product Features

* High-accuracy: Each of the eight pick-up heads is equipped with a FLYING vision alignment camera to guarantee high accuracy.

* High-speed: Maximum placement speed reaching 0.086s/chip.

* Each mounting head has its own Z – direction closed-lo

op stepper motor, which is designed for vertical motion.

* Places SMD components from 0603 to 7474, including resistors, capacitors, standard and irregularly shaped LEDs.

* Suitable for all LED lighting products, including flexible PCB strips, circular LED light bulb boards and even irregularly shaped boards. Assembles LED PCBs up to 1.5 meters long in a single pass.

* Provide non-stop circulating production for small size PCBs.

* Built-in vacuum pump, no outside air source needed.

* Heavy marble platform support to ensure long-service life.

* Excellent quality hardware support by using international famous brands ensure placement repeatability and precision.

* Self-developed software simplifies production, easy operating and programming.

Excellent Quality Hardware Support

Ball Screws: KURODA / THK / NSK (Japan)

Linear Guide: HIWIN (Taiwan)

Servo Motors & Drivers: PANASONIC (Japan) / HCFA (China)

Stepper Motors & Drivers: MOONS (China)

Cables & Tank Chain: IGUS (Germany)

Solenoid Value: CKD (Japan) / MAC (America)

IPC: Independent Research & Development

Our advantages:

1. Professional automated electronic manufacturing equipment for more than 20 years.

2. Own brand, own patents, customized design and solutions, provide after-sales service such as installation training worldwide.

3. Quick respond, 1 day parts delivery, 1 month machine lead-time.

4. Competetive price, the same performance price is lower than half of foreign brands.

Contact:

WhatsApp/Skype:+8619898193772

Email:marie@smthelp.com