Current situation of DIP Line in Electronic Machining

Operators tend to be younger, unstable and mobile, resulting in high labor costs and training costs;

l product quality can not be guaranteed, often appear: floating high, leakage, misinsertion, anti-interpolation and other adverse phenomena;

The output efficiency is low, the output is guaranteed completely by the personnel plug-in proficiency degree or the extension working hours,

the production scale cannot expand, the market competition ability does not have the superiority;

With the advance of industry 4.0 and factory intelligence, and the rising labor cost, the industry is pushing special-shaped plug-in machine instead of manual plug-in. In order to improve the market competitiveness, comprehensive profit level and the strong demand for product quality from the main internal and external customers, the companies must change the existing DIP production mode and realize the fine product management.

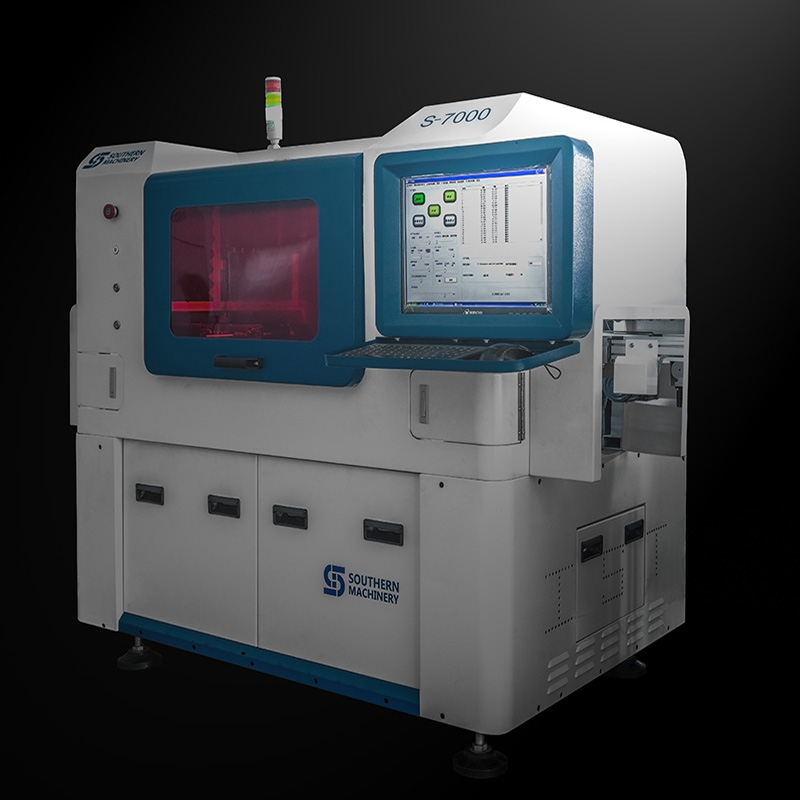

S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine S-70LD Odd Form Insertion Machine

S-70LD Odd Form Insertion Machine

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist