Tape terminals that can be handled:

Zierick terminal P/N 1021/6021/1198/6198

TE Connectivity TAB, FASTON 6.35mm [.250in] or 4.75mm [.187in]

Tab Fit (mm [in]) = 6.35(±0.07mm) x 0.81(±0.03mm) [.250(±0.03 in) x .032(±0.001 in)

Pitch: 0.2 in (5.08 mm)

Insertion rates up to 2 per second at 0.2 in (5.08 mm) pitch.

Up to 4 different components can be applied in one machine Apply products at up to 4 different angles

insertion verification, and Inward clinching/Outward clinching/”N”. (Optional)

Windows-based operating system

Quick change head system, allow production flexibility. (Optional)

Able to process any manufacturer’s reeled through-hole

Visual system: Industrial specialized high definition camera and the development of automatic visual correction software of vision system, automatic correction, insertion accurately

Operating system: Industrial computer + motion control card. Windows environment to run the operation of the software, the production data, management data, equipment parameters, all I/O signal diagnosis, etc. can be finished on the host.

PCB board handling equipment(loader+unloader machine) ready for Industrial 4.0.

Pass the IPC-9704 stress-test standard to ensure that the stress value of each insertion is within ±400ue

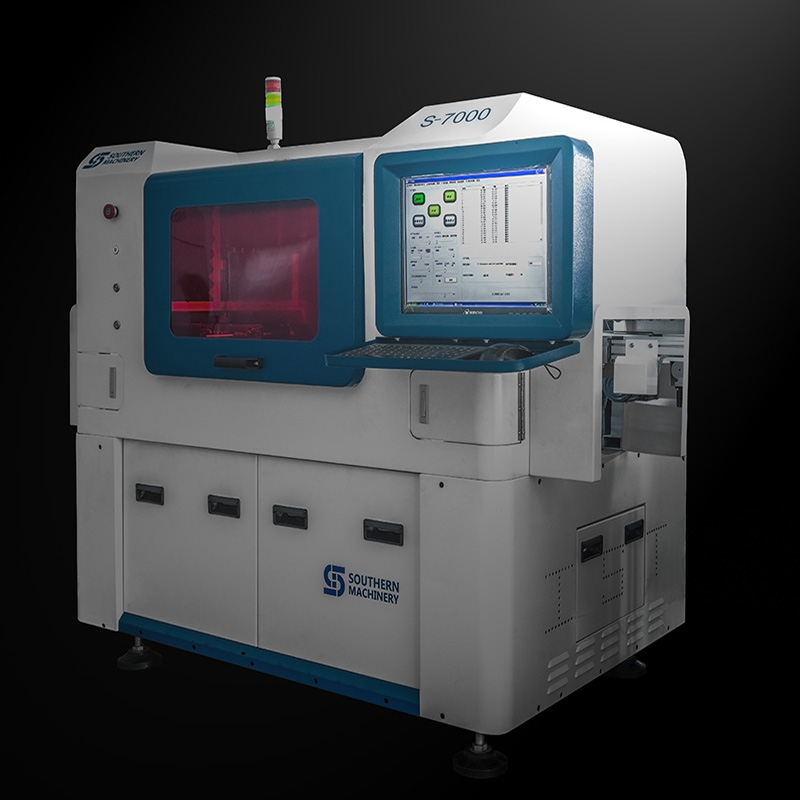

Machine specifications

| Equipment size | 1700mm*1300mm*1600mm (2 heads) |

| Packaging | Tape terminal, bulk terminal |

| Equipment weight | 1200KG |

| PCB size | 380mm*280mmm (enlarged size can be customized) |

| Number of insertion heads | 1-4 Optional |

| terminal thickness | ≥0.5mm ≤1.2mm |

| Vertical error | ≤0.8° |

| PCB requirements | The insertion hole is 0.5±0.1mm larger than the component foot |

| Insertion angle | 360°( increment 1°) |

| Body distance | The distance between the components ≥ 2mm |

| Clinch | Inward clinching/Outward clinching/”N” |

| Humidity | 30%-70% |

| Display system | 17-inch color LCD monitor |

| Feeding system | Tape feeder or Bowl feeder + feeding guide |

| Motion accuracy | 0.001mm/pulse |

| Motion system | Panasonic controller, motor |

| Programming function | Online visual programming, visual correction, EXCEL |

| Data import | USB interface import, manual entry |

| Communication interface | RS-232C (can be connected to MES system) |

| Power | Single 220V/AC, 50/60HZ, 2KVA |

Feeding and Cutting system

The design tape feeder according to the terminal width:

Insertion system and Clinching system

Design insertion head according to the terminal thickness:

insertion verification, and Inward clinching/Outward clinching/”N”. (Optional)

Software programming system

The main operation interface is divided into the following six areas from top to bottom, left and right.

Operation panel area/ Image and video area/ Production data area /Program display area /Status prompt area /Set up ribbon

Application industry

Home appliance industry.The car industry. The power industry. Other electronics industry: digital watches, electronic components, etc

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist