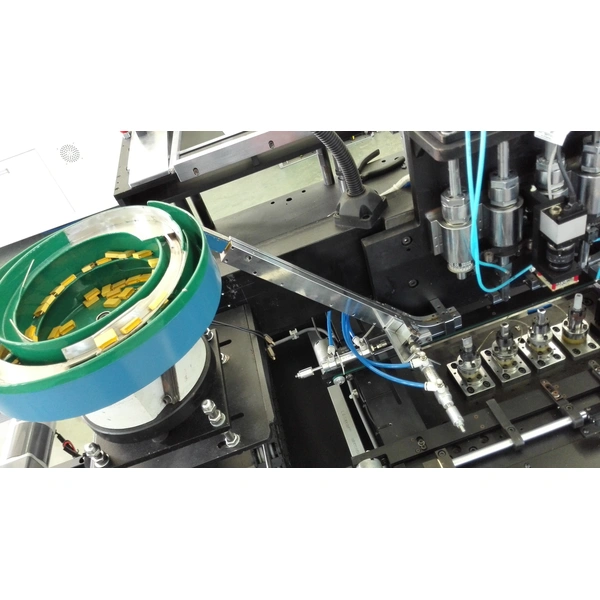

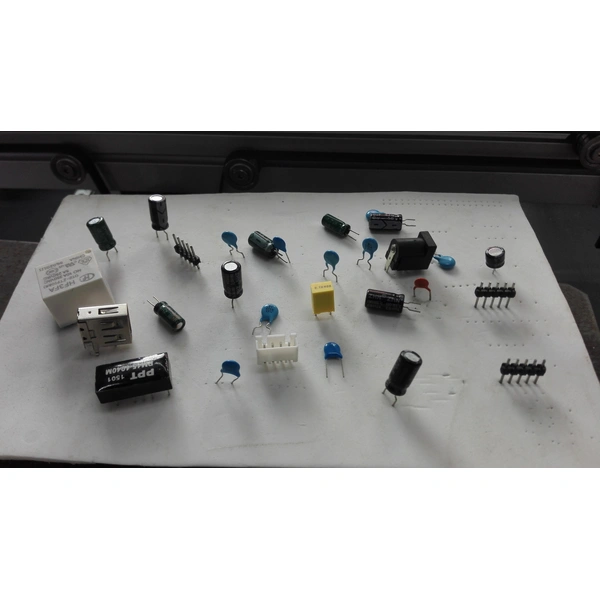

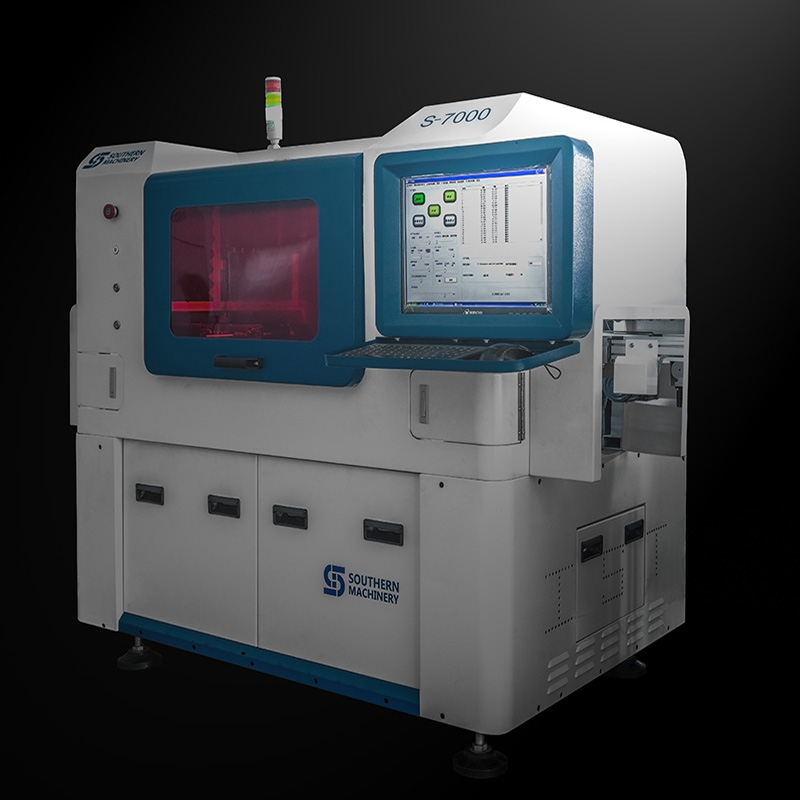

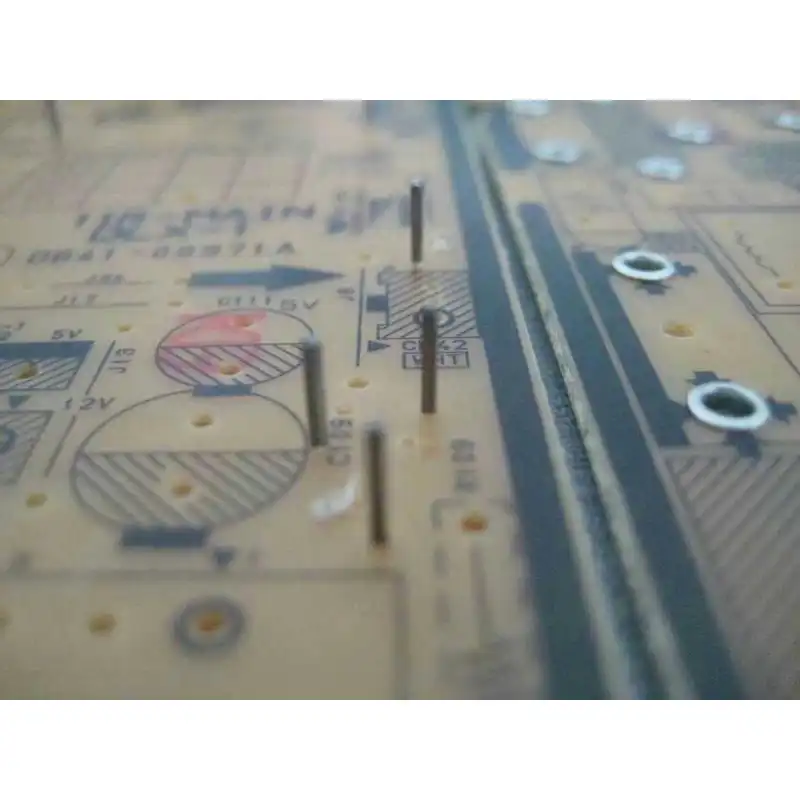

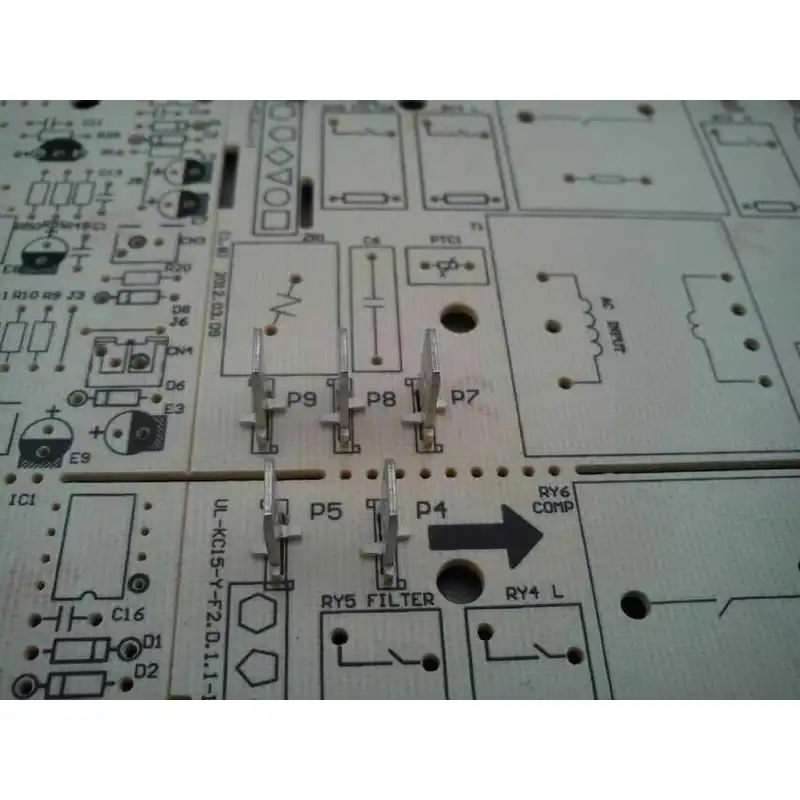

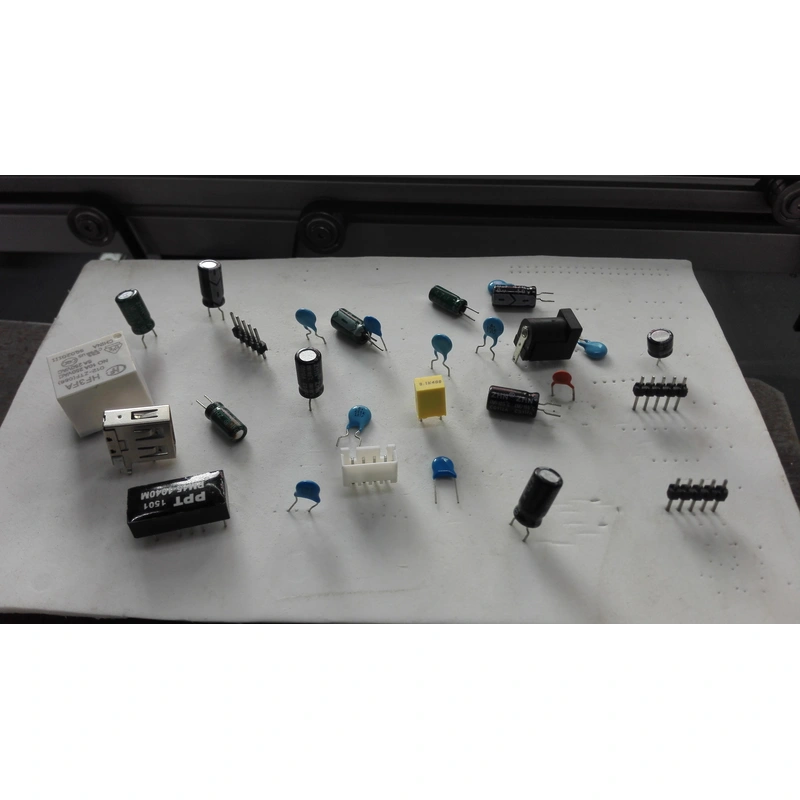

With the growth of the world economy,the tighter labor markets and product control requires electronic parts processing quality and production speed higher and higher。 In order to achieve the electronic assembly automation,According to the needs of odd-form inserter,to insert the packaged or bulk pack component in the hole of PCB accurately need to use a machine to replace manual production. But at present most of the odd-form insertion using PCBA Manual Insertion, low-efficiency 、 low-quality , difficult process,high defective rate&scrappage rate, high manufacturing cost;The imported equipment needs high input cost,returns are very long term,high spare parts and maintenance costs。 we hope we can help your esteemed company winning more interests at the lowest cost with maximum efficiency.

[pdf-embedder url=”https://www.smthelp.com/wp-content/uploads/2019/06/S-70LD-LED-Driver-Odd-Form-Auto-Insertion.pdf” title=”S-70LD LED Driver Odd Form Auto Insertion”]

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist