S-6200 using the hydrodynamic water fragmentation, producing very fine water mist,with the speed of sound (V = 360m/s) to form a strong momentum jet to the nozzle, nozzle for cleaning at the top of the formation of a continuous field,crushing the internal surface of the dirt (the nozzle will not be damaged because of its independent device),during the cleaning process the used cleaning water (deionized water or distilled water) automatic direct emissions.

If you are looking for a reliable and efficient nozzle cleaning machine for your electronic products manufacturing factory, you should check out the S-6200 Nozzle Cleaning Machine from SMTHELP. It is a fully automatic machine that can clean your nozzles quickly, thoroughly and safely, using water or solvent. It can remove any solder paste residue, dust and dirt that may affect the quality and performance of your nozzles and PCBAs. It can also dry your nozzles with hot air circulation and moisture detection. It is suitable for different types of nozzles, such as Fuji, Panasonic, Yamaha, Samsung, Juki and more.

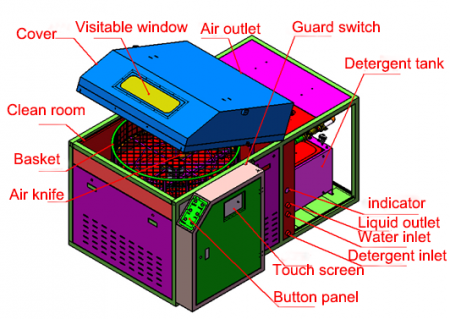

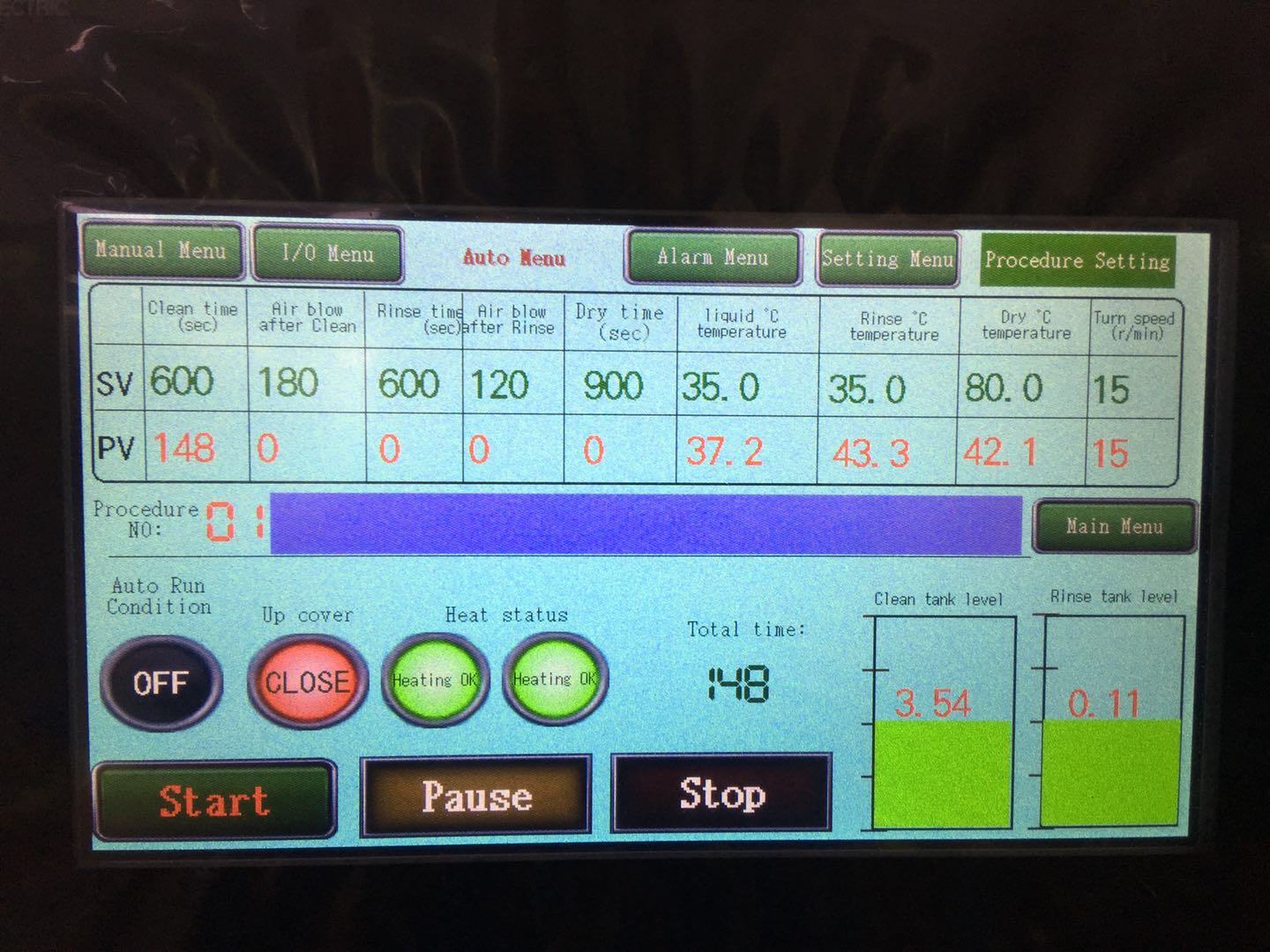

The S-6200 Nozzle Cleaning Machine has many features and advantages that make it the best choice for your SMT process. It has a PLC control and touch screen operation that makes it easy to use and monitor. It has a stainless steel structure that is corrosion-resistant and anti-static. It has an adjustable cleaning pressure, time and temperature that can meet your specific needs. It has a high-efficiency ultrasonic system that can generate multiple frequencies and power levels to clean your nozzles. It has an environmentally friendly cleaning solution that has low consumption and recycling function. It has safety features such as emergency stop, door lock, liquid level alarm and overheat protection.

By using the S-6200 Nozzle Cleaning Machine, you can enjoy many benefits for your SMT process. You can improve the quality and consistency of your nozzle placement and solder paste application by removing any unwanted materials that may cause clogging, wear and tear, and contamination. You can save time and labor costs by eliminating manual cleaning and drying. You can extend the lifespan and performance of your nozzles and feeders. You can enhance your environmental compliance and safety by reducing the impact of cleaning solution on the environment and workers.

The S-6200 Nozzle Cleaning Machine is the perfect solution for your electronic products manufacturing factory. Whether you are Foxconn, Flex, Jabil, Signify or any other global leader in SMT market, you will find this machine to be a valuable asset for your SMT process. Contact us today to get a quote and a free demo. You will not regret it.

Why Use S-6200 Nozzle cleaning machine?

The needs of the development of the electronics manufacturing industry:

1. Miniaturization of components:

The rapid development of the electronics industry makes components more and more miniaturized. 0402, 0201 components are more and more common and used in large quantities, and smaller components will soon appear. The miniaturization of components will inevitably require the corresponding mounter nozzles to be miniaturized, which brings difficulties to the cleaning of the nozzles. If the large nozzles can also be washed with alcohol and thin needle holes. , And now the small suction nozzle has only a few micrometers of aperture. When the blockage occurs, it has to be scrapped.

2. Smaller spacing:

Today’s electronic equipment requires a smaller size and more powerful functions. Therefore, the components on the circuit board are getting denser and the spacing is getting smaller and smaller. If you say that the slight difference in the past patching will not affect too much But now it may be on the neighbor’s territory, causing the product defect rate to increase.

3. The effect of lead-free:

due to the good activity of lead, if there is a slight deviation in the patch, it can be corrected after reflow soldering, but after the lead-free, the activity of copper is greatly weakened. If the patch has a deviation, then There is no chance for correction. 4. To sum up, the requirements for placement accuracy are getting higher and higher, and the slightest difference may be a thousand miles away. The design accuracy of the placement machine is already quite high, but due to various factors, its performance is greatly reduced, and the uncleanness of the suction nozzle is also an important factor.

Economic benefits:

1. Reduce the purchase cost of the nozzle

A scrap of the suction nozzle is often caused by excessive dirt or related accidents. The problem can be solved fundamentally after using this machine. The original nozzle is expensive, and the economic benefits are considered in the long run.

2. Reduce unnecessary labor

The traditional cleaning method requires a lot of manual processing. After using S-6200, no special person is required from now on, and it is all done by the machine.

3. Reduce the product defect rate.

The unclean suction of the suction nozzle is easy to cause the sliding of the components and the occurrence of the throwing phenomenon, resulting in an increase in the product defect rate.

4. Improve SMT production efficiency

Correct cleaning keeps the suction nozzle in a brand new state for work, avoids recognition errors, and greatly improves productivity.

Functions:

Thoroughly clean the dirt on nozzles which ultrasonic cleaner can not clean.

Strong clean power for nozzles, even the smallest nozzle hole.

Very good cleaning effectiveness, extend the lifespan of the nozzles.

No damage to the coating layer of the nozzle and its reflector panel.

Only use DI water or distilled water.

Auto-clean and dry.

Easy operation.

Right for all kind of mounter nozzles.

Specifications:

| ITEM | S-6200 SPEC |

| Air supply | 0.5~0.7Mpa |

| Power supply | AC220V,1A |

| Clean liquid | Purified water or DI water |

| Clean time | 3~6min |

| Dry time | 1~3min |

| Spray pressure | ≤0.55Mpa |

| Clean liquid consumption | ≤150cc/Hour |

| Nozzle range | Min01005~Max hole diameter¢2.0mm |

| Jig spec | 24holes |

| Machine size | L665*W555*H475(mm) |

| Machine weight | 30KG |

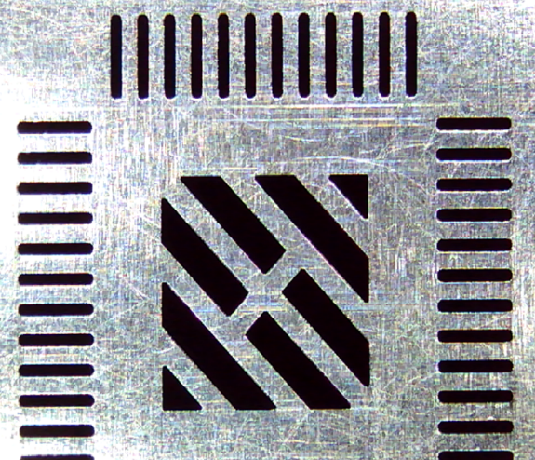

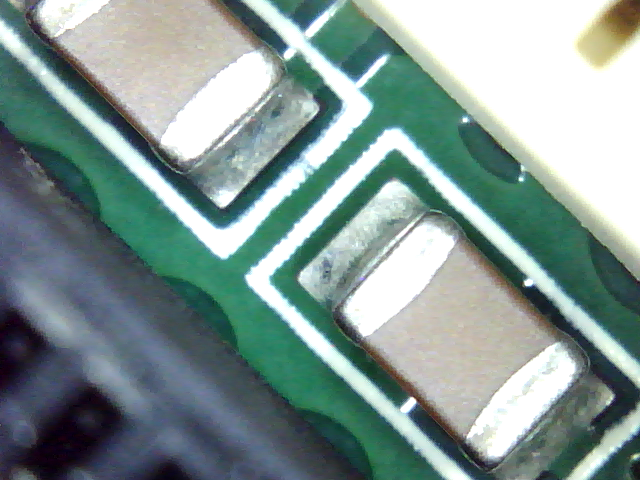

Cleaning result compare with Ultrasonic cleaner:

cleaning result A:

cleaning result B:

Video Description

[videopress aRbiXrcX w=”800″ at=”800″]

Contact

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT