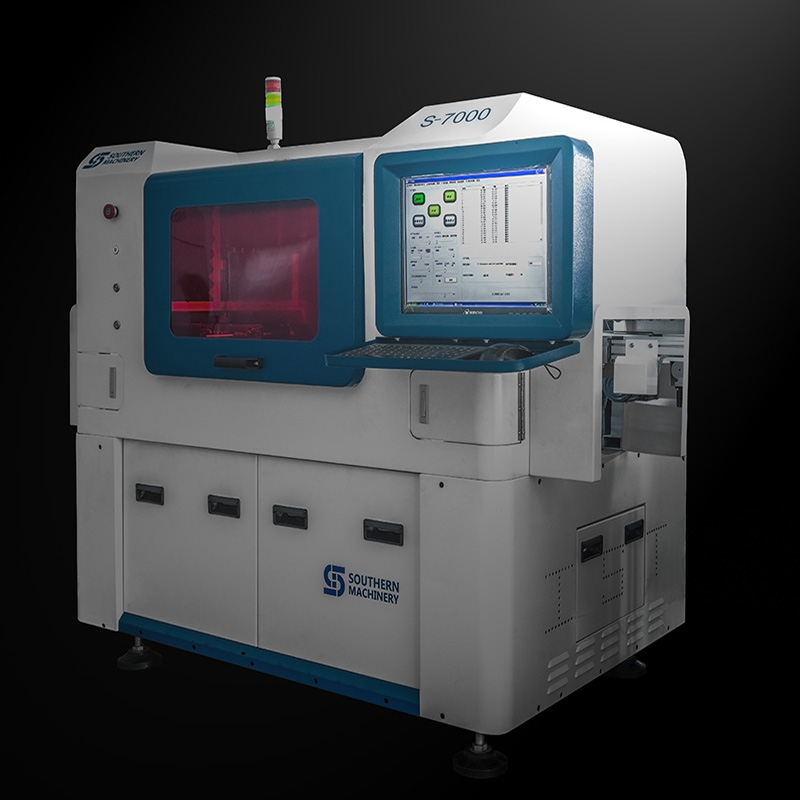

-Highest Throughput

•18,000 CPH Spec Speed

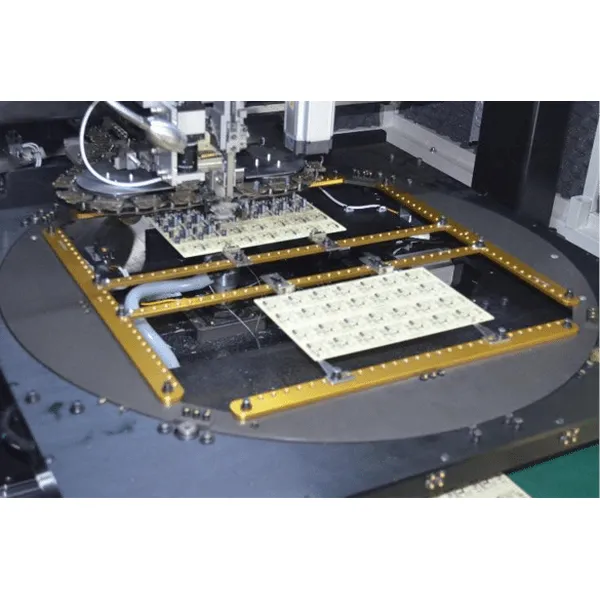

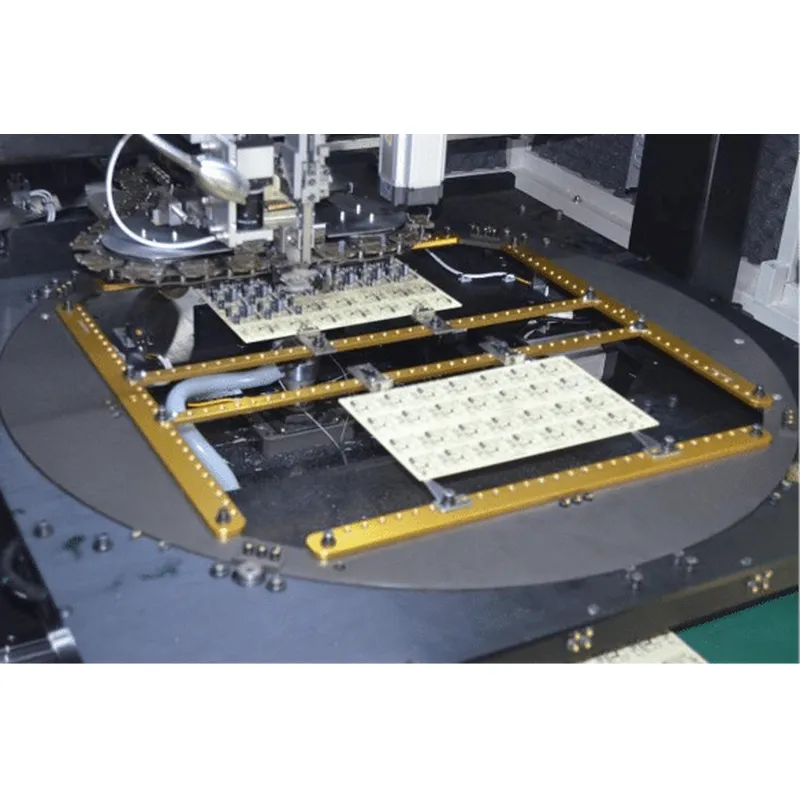

-Strong Machine Flexibility

• Expandable from 10 inputs up to 100 inputs

• Inserts at 1 degree increments up to 360 degrees

• Inward clinch option to increase bottom side density

– Lowers Cost of Ownership

• Low Energy costs. • Minimal preventative maintenance required. RMB2,000/Month/Unit

– Easy to Use User Interface

• Easy operation, use Excel program and USB input. • Off-line programming available

• Components available: Capacitors (electrolytic, ceramic,

box, and film), transistors, diodes, LEDs, connectors, tact

switches, coils, potentiometers, lamps, fuses, etc

jack@smthelp.com WhatsApp:+8615622888481

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist