Description

It is mainly used for automatic cleaning of SMT solder paste stencil, red glue stencil, red glue copper mesh, scraper, PCBA, and cleaning fluid circulation. Use, rinse DI water can be used in closed loop or open loop.

Advantage

An energy-saving environmental protection, batch cleaning, integrated high-end cleaning machine. It can automatically complete cleaning, rinsing, drying process by just push the start key.

- Powerful Cleaning - Dual spray nozzles provide high-pressure cleaning to remove all flux residue, solder paste, oils, and particulates from PCB assemblies. Gets boards ultra clean.

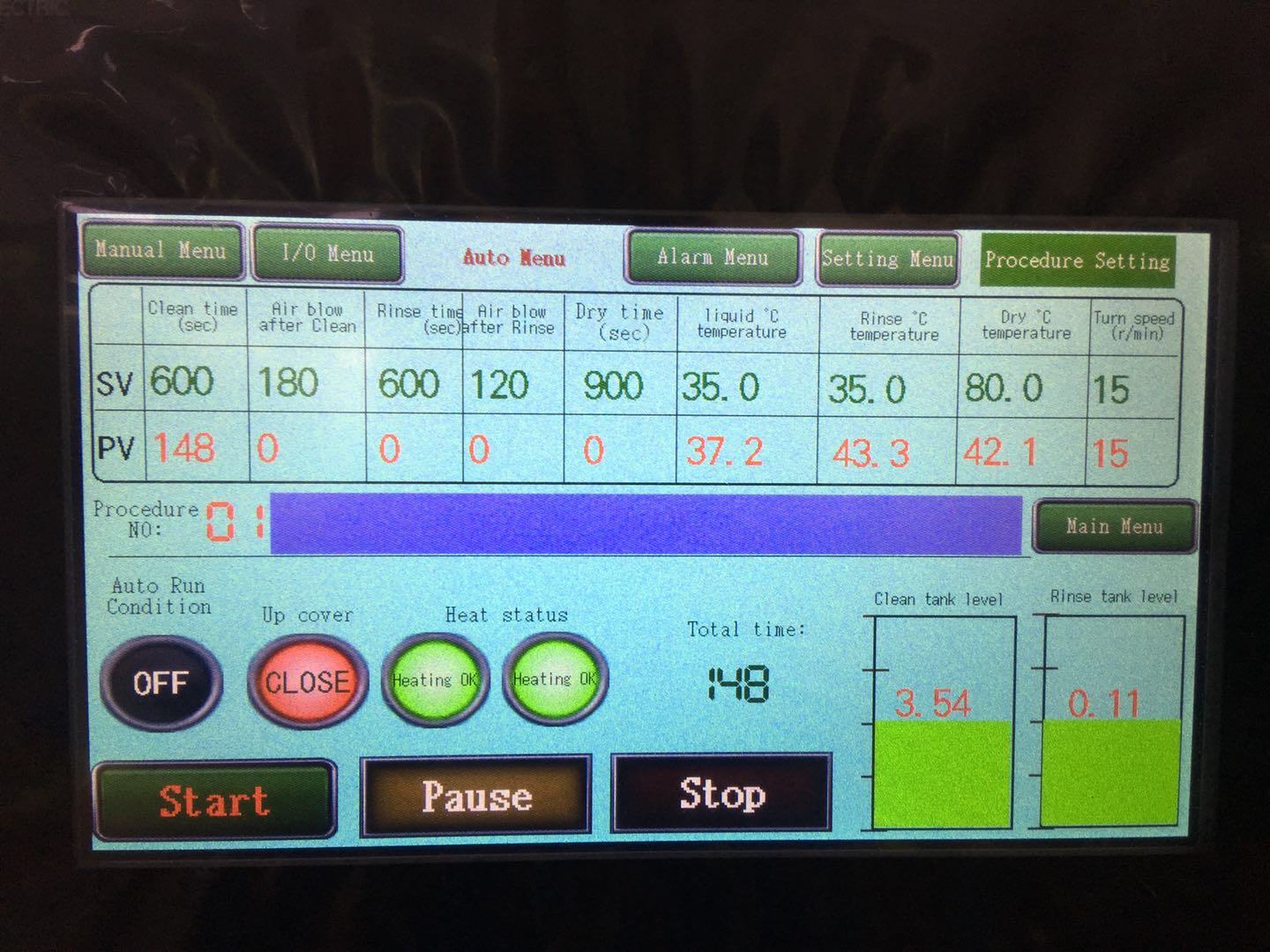

- Adjustable Settings - Cleaning process can be customized based on type of PCBs, level of residue, and production needs. Settings can be saved for repeat jobs.

- Automated Process - Integrated wash, rinse, and drying cycles are fully automated. Just load boards and press start for hands-free cleaning.

- Multi-Function - Not only cleans PCBAs, but can also clean stencils, pallets, screens, jigs, and other production equipment.

- Compact Design - With a small footprint, the machine takes up minimal floor space in production areas. Easy to move and install.

- Low Maintenance - Durable construction and easily replaceable filters make the machine reliable and low maintenance.

- Eco-Friendly - Closed loop fluid system recycles and filters wash fluid minimizing waste. Low energy consumption.

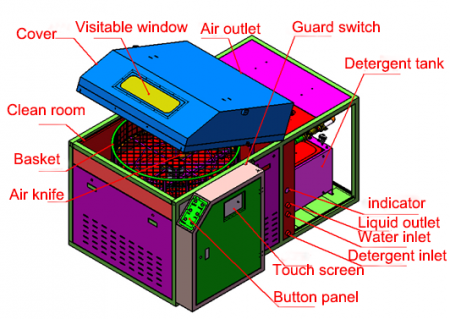

Main modules of equipment

The equipment has an integrated structure and automatically completes the cleaning, rinsing and drying processes in one cavity.

1. Cleaning: Cleaning with water-based cleaning fluid, the time can be set;

2. Rinsing: DI water rinsing, time can be set;

3. Drying: hot air drying, time can be set.

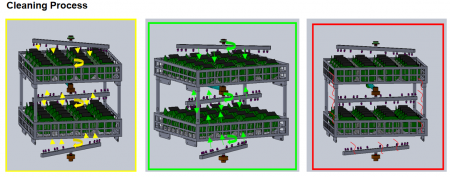

Basic cleaning process

Put the PCBA or stencil into the basket→ clean with chemical solution → rinse with DI water → dry with hot air → take out PCBA or stencil

Cleaning method

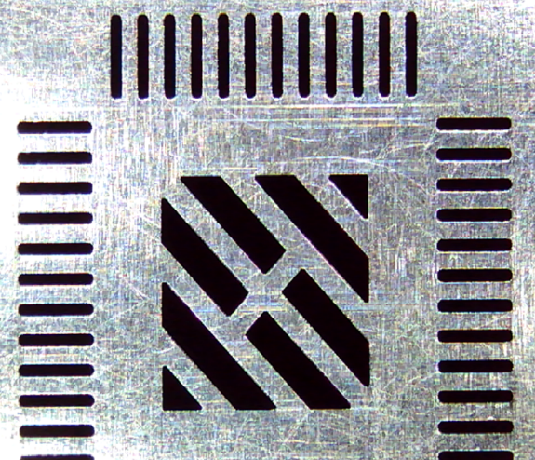

Direct spraying to PCBA/stencil surface on both top and bottom side

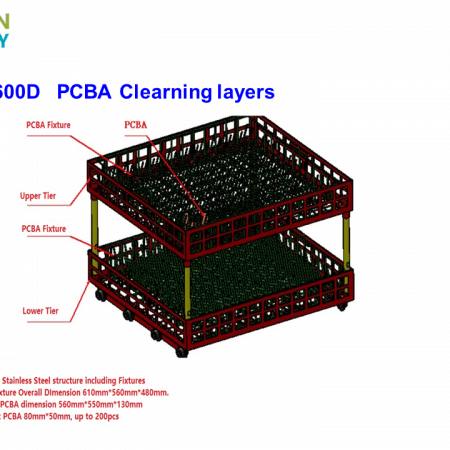

Customized baskets

Specs

Features

1. Open loop and closed loop methods, suitable for cleaning SMT steel mesh, copper mesh, resin mesh; misprinted PCB; PCBA, etc.

2. Unique motion mechanism design - the steel mesh moves forward and backward, and the spray rod and air knife are fixed, making the machine run more stable.

3. The water-based cleaning fluid is circulated and filtered in real time to extend the saturation time of the pollutant load and is suitable for precision steel mesh cleaning.

4. Large flow 4 air knife system, hot air drying quickly.

5. The overall body is made of 304 stainless steel, which is resistant to acid and alkali corrosion and is sturdy and durable.

6. One-touch operation, cleaning, rinsing and drying can be completed automatically at one time according to the set program.

7. The cleaning room is equipped with a visualization window, so the cleaning process can be seen at a glance.

8. At the end of cleaning, compressed air is used to recover the residual chemical liquid in the pipes and pumps, effectively saving 50% of the cleaning solution.

9. Color touch screen, PCL control, runs according to program; parameters such as solution temperature, cleaning time, rinsing times/time, rinsing temperature, drying time, drying temperature, resistivity monitoring and other parameters can be set.

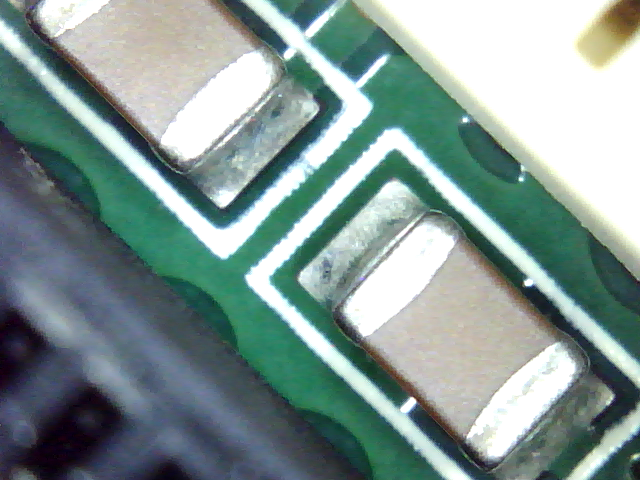

Before and after cleaning