Features:

The body has a streamlined appearance design, and the paint is not peeled off by using the plastic spraying process, which is beautiful and durable.

Two-stage independent full hot air preheating, the temperature is more uniform, so that the PCB can get a good soldering effect.

Patented titanium alloy chain claws, non-stick tin, no board drop, no deformation, long life.

Independent glass observation window, beautiful appearance, easy to operate and maintain.

Tin stove lifts and enters and exits, automatic adjustment and manual adjustment are combined

Equipped with cooling module and temperature compensation module, suitable for lead-free soldering and various process requirements

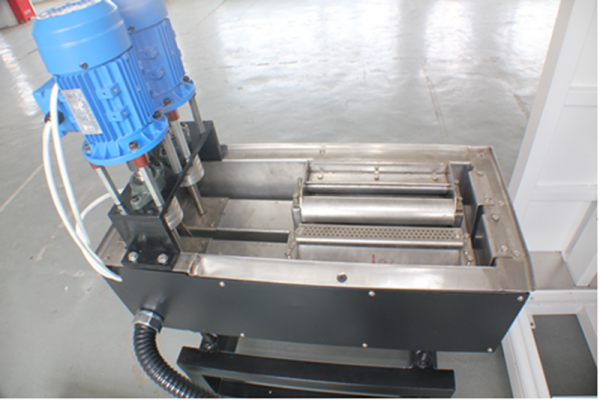

The tin furnace adopts an adjustable nozzle design; the oxidation amount of tin slag is ultra-low, and the liquid tin flow design principle is adopted to reduce the impact oxidation amount of tin. The wave peak can be adjusted with the width of the PCB board, which greatly reduces the amount of tin when soldering small PCB board Oxidation amount, adjustable distance is 50-250MM

The transmission mechanism adopts precise modular design, accurate transmission, long life and easy maintenance.

The rosin spray box is made of stainless steel, and the rosin spray device can be pulled out and disassembled for easy cleaning and maintenance.

Isolated spray device, the flux fume is discharged from the dedicated air duct.

Powerful parameter library function, various PCB process parameters can be called and operated on demand.

Adopt touch screen + PLC control system to ensure the reliability and stability of the system