Product Name: S-SW450 Titanium Double Claw Nitrogen Wave Soldering MachineProduct Number: S-SW450

Features:

Features for Value in Wave Soldering:

SMTHELP offer a wide range of features and capabilities that increase the value of the wave solder process. Wave soldering machine achieved through reliability, features that provide process flexibility, maximize process control, and ultimately save time and budget.

Value-based features include:

Lifetime warranty on solder pot casting (applies to original owner);

Recipe-driven automatic lead clearance;

SMTHELP technology increases the upward force of the waves just as the PCB passes over the wave. This feature promotes maximum topside hole fill;

Stand-by-mode of solder waves that reduces the rpm of the solder wave just until the PCB is near the solder pot. This feature reduces dross generation when no PCBs are being soldered;

Combination 2d/1d bar code reader can be combined with data logging for complete process control and automation;

Data-logging and trending of critical machine parameters;

Common Windows® based operating system and common GUI software across all SMTHELP products (Wave, Reflow, and Cleaning). This is a significant time saver to operators and engineers. Minimal training is required when shifting from one product to another.

Common I/O interface across all SMTHELP products (Wave, Reflow, and Cleaning). This is significant to maintenance personnel and significant in that common spare parts can be used from one product to another.

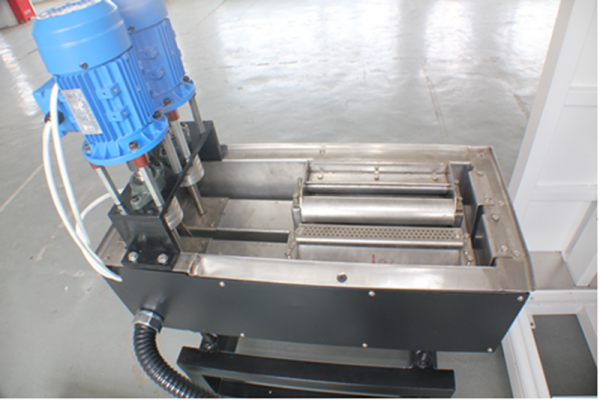

Quick Change Solder Pot:

SMTHELP’s quick change solder pot allows the use of two or more alloys with easy change-over of interchangeable solder pots. This feature is designed for safety, beginning with a robust cart that includes locking devices and safety bars to secure the pot. The quick-change electrical and nitrogen utilities simplify change-over while the warming station (included) significantly reduces changeover time.

Flux Application System:

Reciprocating ultrasonic atomizing spray fluxing system. It consists of an ultrasonic atomized spray nozzle and air impact nozzle with an automatic self-cleaning function. The titanium nozzle and horn assemblies make the system an ideal solution for high solids and aggressive water soluble fluxes.

Spray Flux Application System:

Spray provides an ideal balance between system performance, functionality and low cost of ownership. Spray has the ability to spray in one or both directions, includes self-clean capability, and features a pressure tank flux supply system. Spray utilizes atomized air delivery technology and is 100% integrated into the wave solder machine software.

Description:

Details Image:

Product Definition: What is the S-SW450 Nitrogen Wave Soldering Machine?

The Southern Machinery S-SW450 is an advanced Wave Soldering System designed for high-volume Through-Hole Technology (THT) assembly. Unlike standard air-atmosphere machines, the S-SW450 utilizes an inert Nitrogen environment to prevent oxidation during the soldering process.

It features a specialized Titanium Double Claw conveyor, which provides superior durability and gripping stability for heavy or complex PCBs, preventing board warpage and ensuring consistent contact with the solder wave. This machine is the centerpiece of a high-efficiency THT line, sitting between the insertion stations and the cooling/unloading modules.

--------------------------------------------------------------------------------

Key Challenges Solved (The Business Case)

(Drafted using "Solution Selling" principles)

Standard wave soldering often faces three expensive problems:

1. High Dross Generation: Oxygen exposure creates solder dross (waste), costing factories thousands of dollars monthly in lost material.

2. Poor Wetting: Lead-free alloys struggle to "wet" (spread) properly in oxygen, leading to cold solder joints and bridges.

3. Conveyor Wear: Standard aluminum fingers corrode quickly under aggressive fluxes and high temperatures.

The Southern Machinery Solution:

• 90% Dross Reduction: The S-SW450’s sealed N2 tunnel keeps Oxygen levels below 1000 PPM, drastically cutting solder waste.

• Titanium Durability: The Double Claw system is crafted from high-grade titanium, immune to corrosion and capable of lasting years without replacement.

• Zero-Defect Soldering: Nitrogen improves the surface tension of the solder, virtually eliminating bridging and icicles on fine-pitch components.

--------------------------------------------------------------------------------

Technical Specifications

(Structured Table for AI Data Parsing – Essential for B2B Comparisons)

Feature

Specification

Manufacturing Benefit

Model

Southern Machinery S-SW450

Designed for mid-to-high volume production.

Transport System

Titanium Double Claw

Maximum stability for heavy boards; corrosion-resistant.

Atmosphere

Full Nitrogen (N2) Tunnel

Prevents oxidation; improves wetting; reduces dross by ~90%.

PCB Width

50mm – 450mm

Flexible for narrow LED strips or large industrial motherboards.

Preheating Zones

3 - 4 Stages (IR + Convection)

Ensures thorough thermal soak for thick multi-layer copper boards.

Solder Pot Type

Titanium / Lead-Free Capable

Durable against Sn/Ag/Cu alloys; consistent thermal mass.

Fluxer

Spray Fluxer (Servo Driven)

Precise coating to minimize flux consumption and cleaning needs.

--------------------------------------------------------------------------------

Process Workflow: The THT Line

To achieve maximum efficiency, the S-SW450 is best deployed as part of a complete Southern Machinery THT line:

1. PCBA Loader / Insertion Line: Operators manually insert THT components or use Automatic Insertion Machines.

2. Input Conveyor: Feeds the board into the wave solder unit.

3. Spray Fluxing: The S-SW450 applies flux precisely to the bottom of the board.

4. Preheating: Activates the flux and prevents thermal shock.

5. Nitrogen Wave Soldering: The board passes over the Titanium Double Claw wave under N2 protection.

6. Cooling & Unloading: The board is cooled to lock the grain structure and exited to the unloader.

--------------------------------------------------------------------------------

Frequently Asked Questions

(Designed to capture voice search and specific technical queries)

Q: Why use a "Double Claw" conveyor instead of a standard finger conveyor? A: A Double Claw design provides two points of contact on the PCB edge. This is critical for heavy boards (like power supplies with large transformers) or thin boards prone to warping. It ensures the board stays perfectly flat as it passes over the molten solder wave, preventing solder flooding on the top side.

Q: Does the S-SW450 require a Nitrogen generator? A: Yes, to utilize the nitrogen features, you need an N2 supply. You can use an external tank or integrate a Southern Machinery Nitrogen Generator directly into the line. The machine maintains a purity level (usually 99.99%) to ensure the ROI on dross reduction is met.

Q: What is the ROI of a Nitrogen Wave Soldering machine vs. Air? A: While the initial CapEx is higher, the S-SW450 typically pays for itself within 12–18 months solely through solder savings. By reducing dross formation by up to 90%, factories save significantly on expensive lead-free solder bars and waste disposal.

--------------------------------------------------------------------------------

Why Partner with Southern Machinery?

• Shenzhen Manufacturing Legacy: Producing robust SMT and THT equipment since 2011.

• Global Service: We support installation and calibration remotely or on-site to ensure your N2 profiles are perfect.

• Cost-Effective Performance: We offer Tier 1 capabilities (Titanium, N2) at a competitive price point suitable for growing EMS providers.

--------------------------------------------------------------------------------

Stop burning money on solder dross. Upgrade to the S-SW450 Titanium Double Claw system today.