Are you struggling to overcome those problems?

1.Difficulty of recruitment

2.Low production efficiency

3.Low quality

4.High labor cost

What we can offer:

1. Unprecedented high efficiency

Replace 3-5 soldering workers, with accurate and stable soldering quality, bringing higher efficiency

2. More than 10 years service life

Full and even solder solder joints, better product quality

3. Simple soldering

Quick temperature rise and stable, controllable soldering amount and temperature and solder paste output speed, and has the solder reflow function.

Comparison of Artificial Soldering Exclusive Cutter for Electronic Components

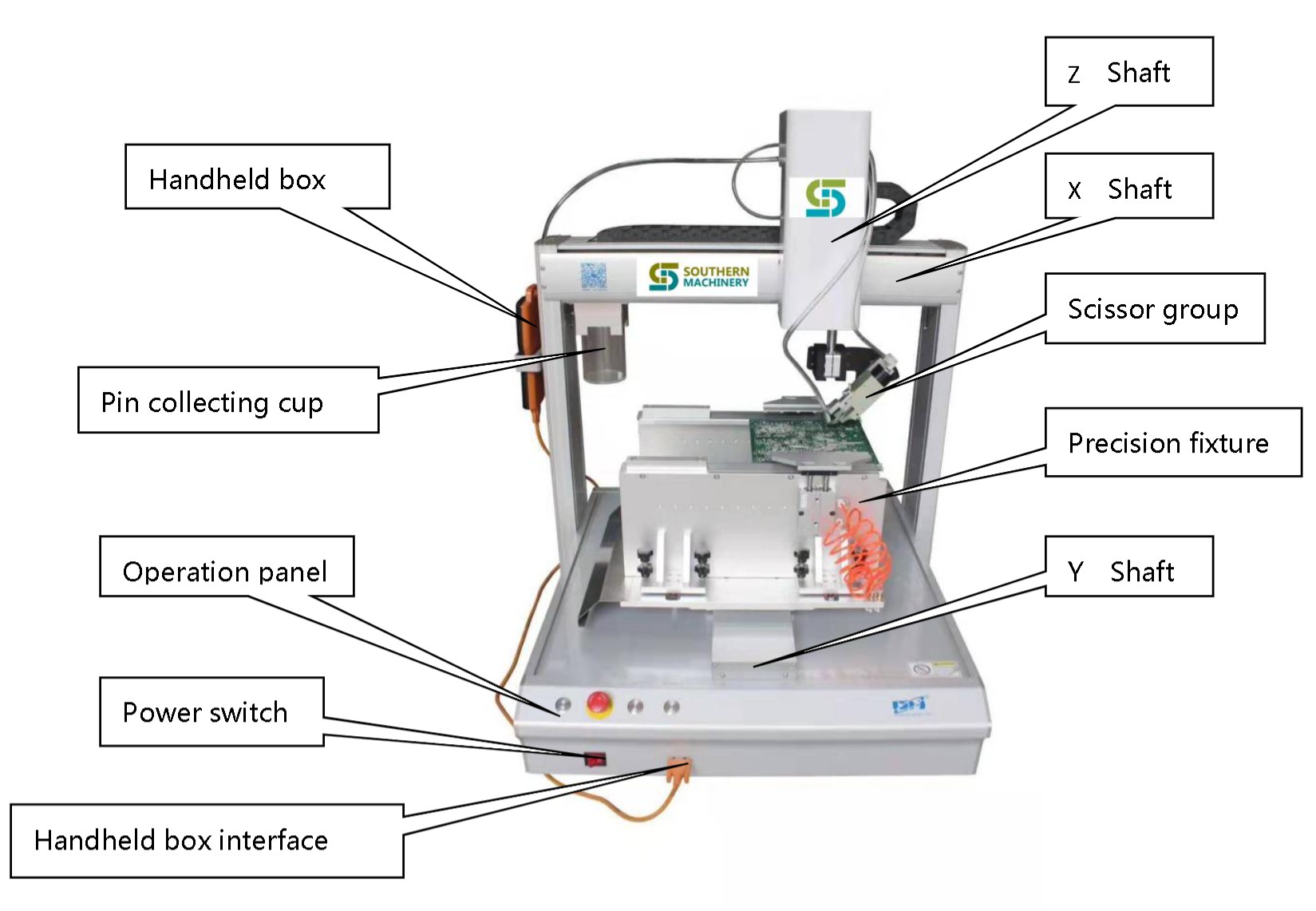

Exclusive Cutter for Electronic Components

The cutter body and head are independently developed, and are more suitable for automatic cutting of PCBA lead. Applicable cutter heads can be designed according to different products. The cutter head is made of tungsten steel, which is more neat and durable.

Applicable PCBA

PCBA MAX: X=250MM, Y=320MM

Process edge size MIN:D=3MM (If there is no process edge, a fixture must be added)

PCB thickness: B=0.8~2.5MM

Component lead length: A<6MM (before cutting)

Component body height: C<110MM

The shortest length of lead is 0.5MM

Component diameter <1.6MM

Instructions

1. The normal operating power of the equipment: 700w;

2. The equipment automatically cuts the lead one by one according to the pre-programmed path and sucks them away. The length of the cut lead at each point can be controlled individually, and the waste pins can be automatically recycled;

3. The cutting efficiency is more than 7200 points/H, which is suitable for PCB veneer or imposition cutting lead within the size of 250*320;

4. The maximum diameter of copper pins that can be cut is 1.6mm, the length of the cutting lead is adjustable from 0.5-5mm, and the precision of the cutting lead is less than ±0.1mm.

Operation Process

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist

WhatsApp/Skype:+8619898193772

Email:marie@smthelp.com