[videopress fS5DMFyI]

Characteristics:

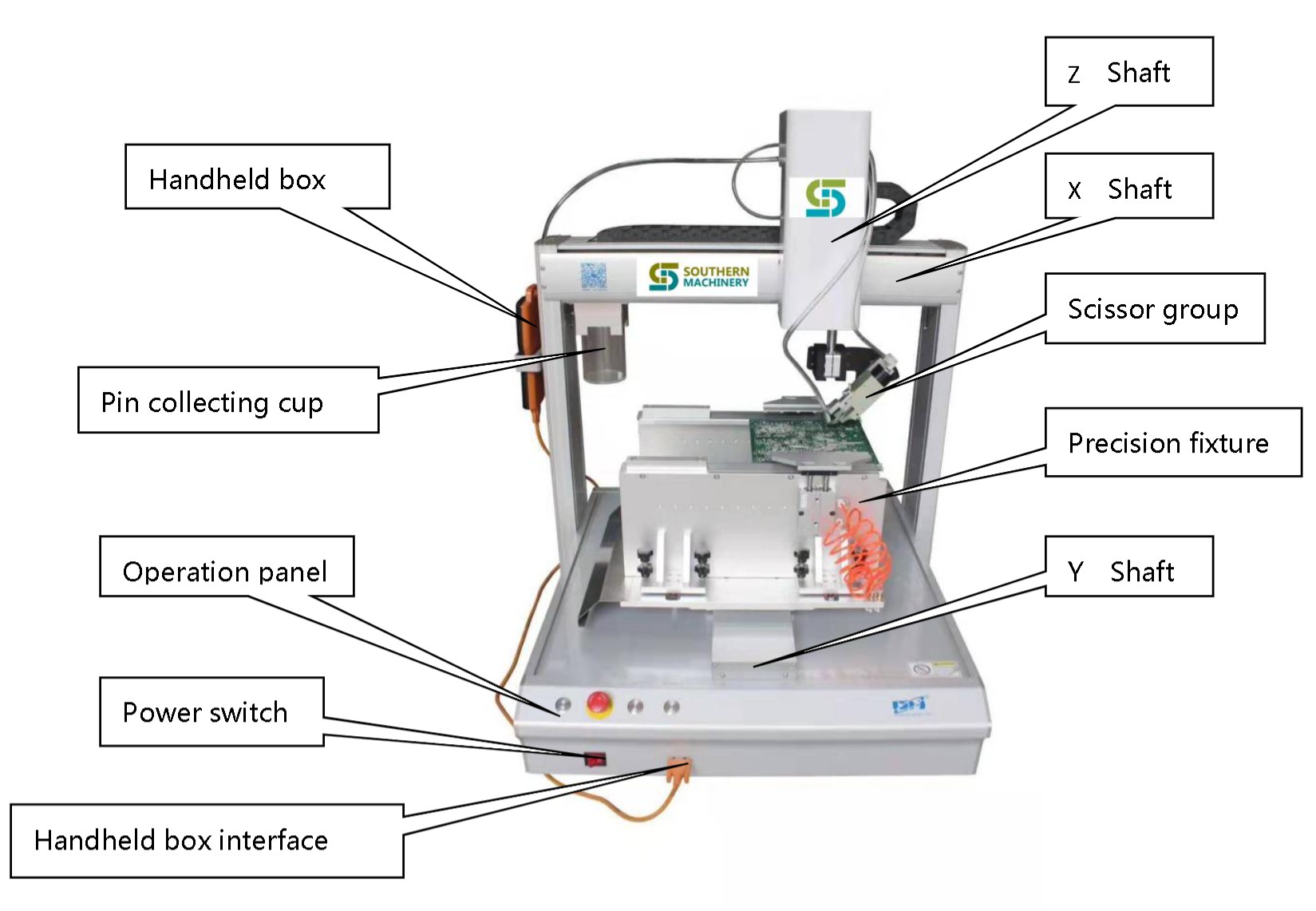

Used for hand-held program design, parameter modification, and equipment status monitoring. After programming or modifying parameters, the handheld box can also be used for other devices of the same model. However, it must be plugged in or unplugged only when the power is off, otherwise the handheld box will be damaged.

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist