Transportador de portão de extensão e retração de PCB

Manual do usuário

Certifique-se de ler atentamente este manual antes de usar * para garantir o uso adequado do produto.

Prefácio

Obrigado por comprar os produtos da empresa, a Companhia de expressar os meus sinceros agradecimentos. Este manual de configuração de hardware, operação do dispositivo e manutenção de diagramas elétricos foram descritos. Por favor, entenda completamente este manual, o uso adequado.

Embora o conteúdo deste manual procure corrigir, mas se houver como quando são encontradas dúvidas ou erros, entre em contato com a empresa.

Aviso:

o dispositivo só pode ser mantido por profissionais e pessoal de serviço ou o treinamento de pessoal qualificado para operar

Antes de ligar, certifique-se de que a fonte de alimentação de entrada externa com a tensão nominal do dispositivo e a potência correspondam

Por favor, equipamento de aterramento confiável

toda a mecânica deste equipamento, a operação deve atentar para a segurança pessoal

Observação:

Por favor, leia este manual do usuário cuidadosamente antes de operar este equipamento, lembre-se Cuidado

Não instale este equipamento nas proximidades de fontes de interferência eletromagnética

Não modifique a caixa elétrica de programas de hardware e software, a transformação em

perigo,

please keep this manual press the manual requires maintenance of equipment

Although the contents of this manual are correct, please contact us if you find any doubts or errors.

packing list:

口 Core machine

口 User Manual

口 as customers have special requirements, please refer to procurement contracts check

Contents

CHAPTER 1 INTRODUCTION

1.1 Overview

1.2 Technical Data

Preparation before use

CHAPTER 2 MACHINE OPERATION

2 .1 boot precautions

2 .2 Operating Instructions

CHAPTER 3 DESCRIPTION OF THE PROBLEM 7

CHAPTER 4 MAINTENANCE 8

Chapter 1 Introduction

1.1 Overview

Used for SMT production line connection transmission, and can make a temporary aisle

This machine features:

Adopt Panasonic PLC, ressaix stepping, precision ball screw

1.2 Technical Parameters

Project | The main parameters |

PCBtransportation direction | Left to right |

power supply | AC220 50 / 60Hz power 5 0 W. |

control method | Button plus Panasonic PLC control. |

Type of transmission surface | Strip |

PCB thickness | 0.7 to 30 mm . |

Conveying height | 880~920 ( adjustable ). |

Preparation before use

Please use 220V single-phase 50Hz capacity fixed power supply above 200W

The machine must be safely grounded and must be connected to the ground bus

The ground wire must be well fixed to the metal part of the fuselage

To ensure safety, it is forbidden to bring your body close to the running equipment

Do not install the machine in dust, oil mist, conductive dust, corrosive gases, flammable gases, moisture, shock, vibration, high temperature and outdoor environment.

Avoid using corrosive solvents to wipe the machine, neutral detergent should be used

Please keep this price manual for future maintenance and maintenance.

Notes:

There is no reliable grounding and there is a danger of electric shock.

After the air is connected, the cylinder valve will act. Please do not put your hand into the machine to prevent pinching.

Chapter 2 Machine operation

2..1 Boot precautions

To ensure safety, physical contact with moving parts is prohibited.

Check for any debris in the machine.

Check for any debris or PCB on the track.

2.2 Instructions

Button function description

Automatically – the knob is turned to the “auto” position word, into the automatic operation device

Manual – When the knob is rotated to the position of “Manual”, the device enters the manual operation state

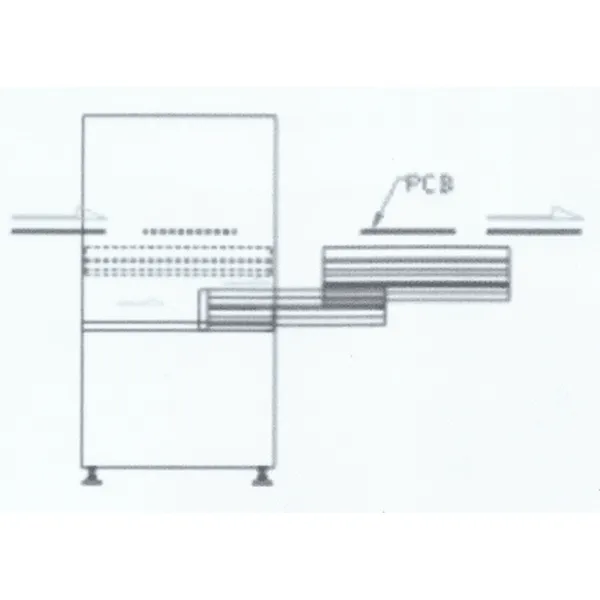

Extend – when running manually, click on the “Extend” button and the docking platform extends out of the rack.

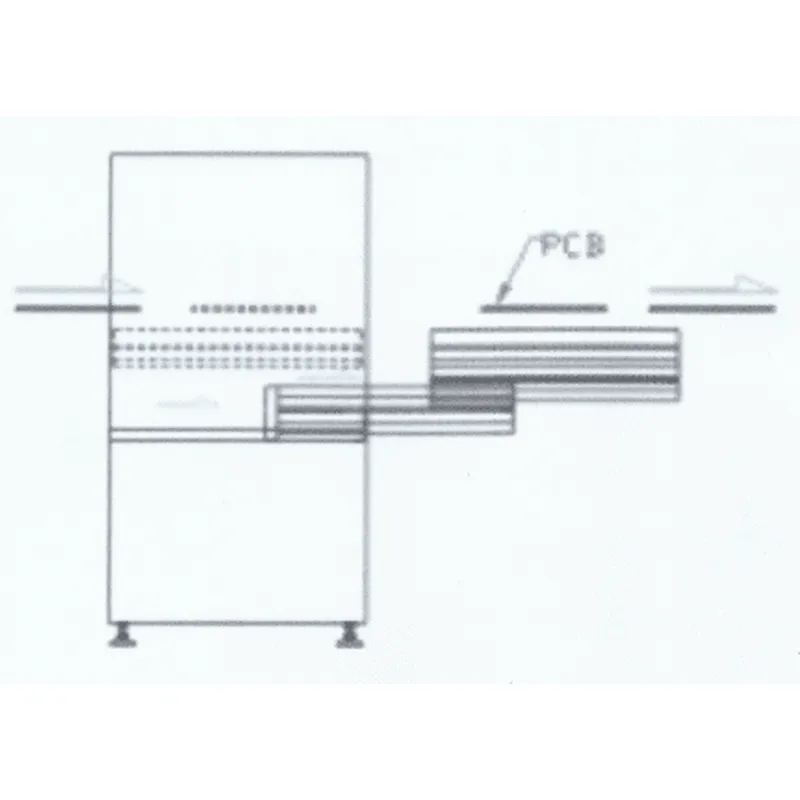

Retracting – When running manually, click the “ Retract ” button, the docking platform will retract the position in the rack , automatically run the device alarm, click the button, the device alarm clears

Pause – When the “Pause” button is pressed, the docking station platform will no longer extend outside the rack

Emergency stop – when the “Emergency stop” button is pressed, the device stops all running actions

Figure 1

Chapter 3 Fault Description

3.3.1 Fault handling and maintenance equipment must do the following points:

The principles familiar with the equipment and electrical schematics.

Familiar with the installation position of each mechanical device and electrical equipment in the equipment, and understand its performance and role.

Correctly analyze the cause of the fault.

Find the faulty part and the failed component

Targeted maintenance.

3.3.2 Frequently fault causes and troubleshooting

Fault content | cause of issue | Approach |

Jam into the board | The height of the left side is different from the height of the upper computer. | Use a spanner wrench to adjust the threaded rod to make the height consistent |

Belt does not turn | Motor is damaged or the belt is too loose | Replace the motor or adjust the tension to tighten the belt |

The main power switch indicator is off. | The switch is broken, the wire is loose, the power cord Open circuit | Unplug the plug and open it to make the panel. Check if the thread is loose. Se estiver solto e recortado, se não estiver solto, substitua o botão |

Capítulo 4 Manutenção

Semanalmente

Verifique se a correia de transporte está muito frouxa e mantenha-a limpa.

Limpe o óleo sujo com um pano ou papel e depois lubrifique o parafuso de esfera.

Testar se a entrega do produto é tranquila.

Verifique se há desgaste no trilho da correia.

Lubrifique o parafuso de avanço por pelo menos 2 semanas.

PCB estende e retrai manual do usuário do transportador de porta da Shenzhen Southern Machinery Sales And Service Co., Ltd