Description:

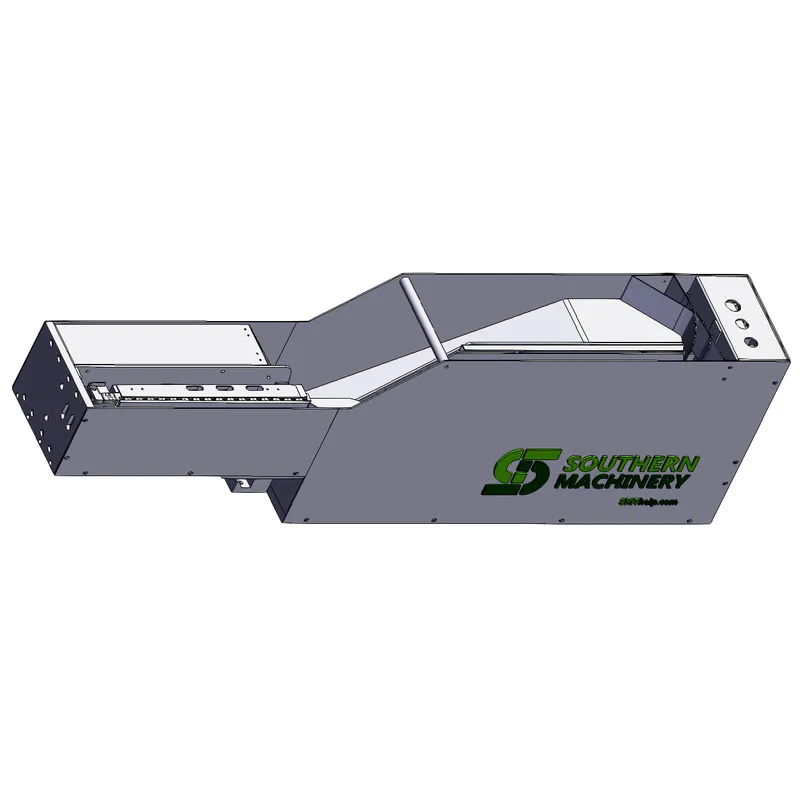

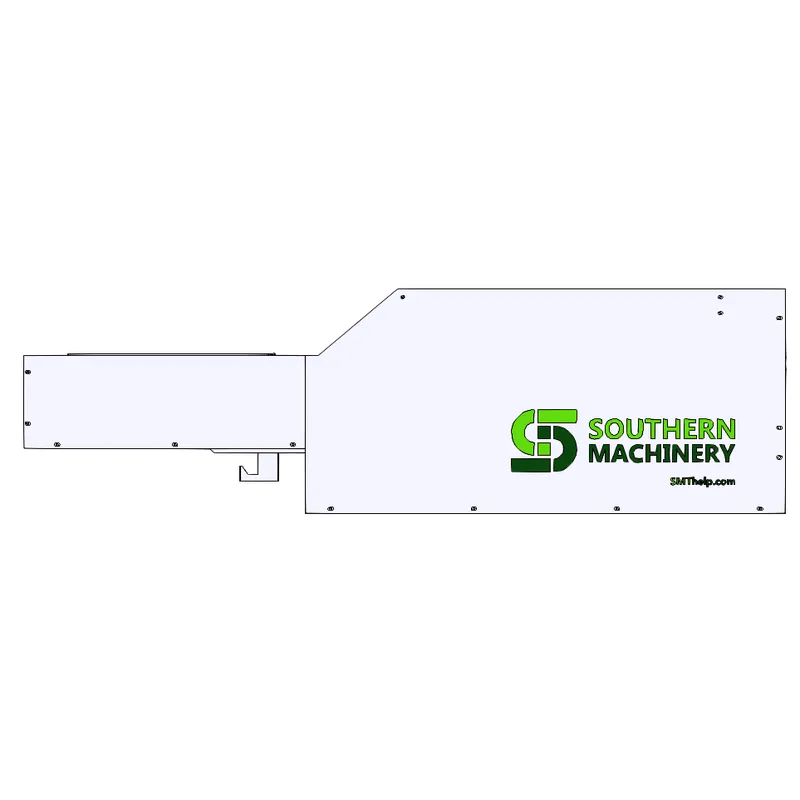

A bulk feeder is an electric device that feeds and regulates the flow of parts or materials to the same fixed pickup position for machines or animals to use. Bulk feeders have various types and purposes, and can be chosen according to different needs and situations. Bulk feeder is also a feeding strategy of animals that eat pieces or whole of other organisms. This feeding strategy usually requires strong physical activities and digestive abilities.

FAQ about bulk feeder:

What is a bulk feeder?

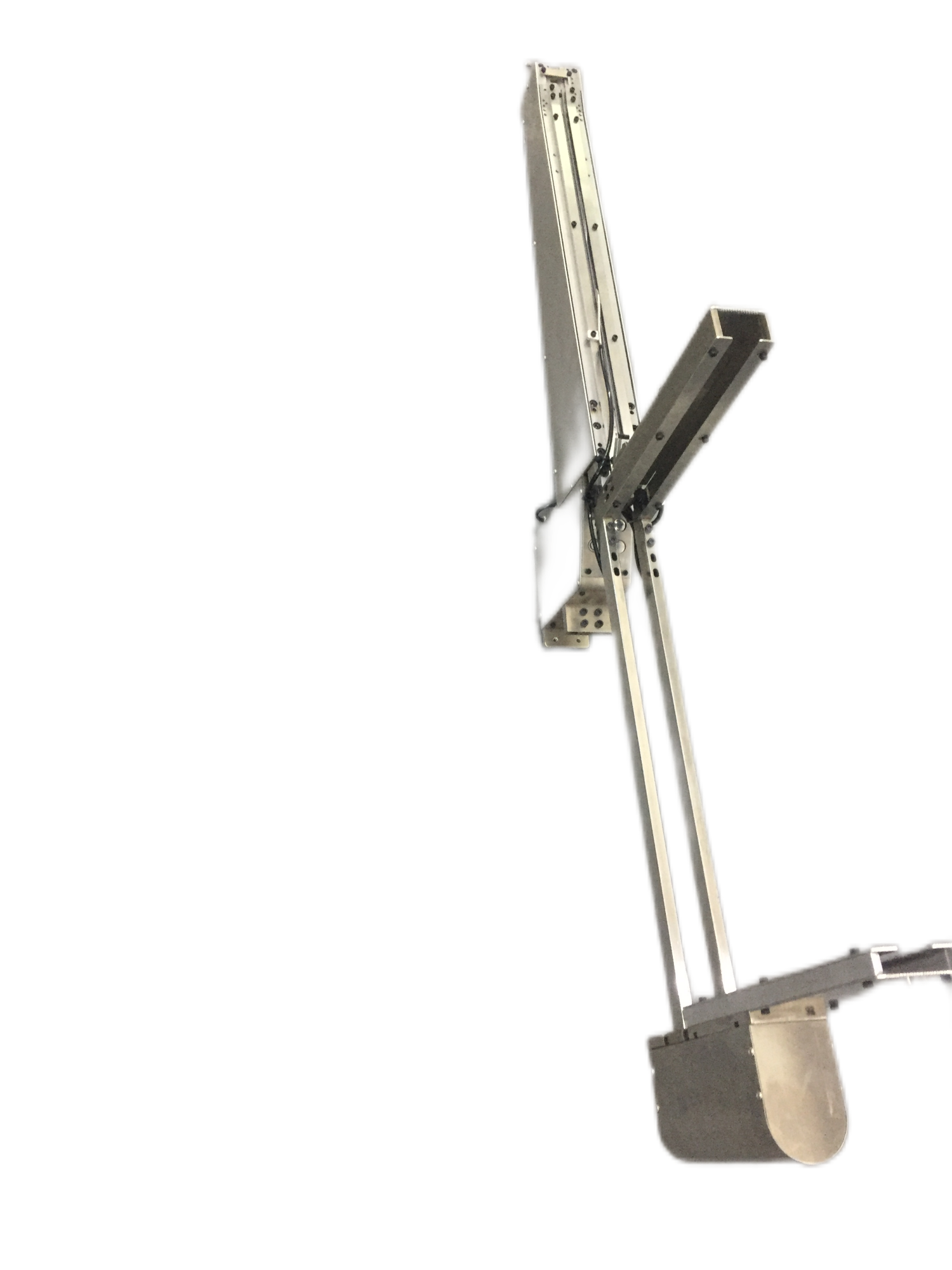

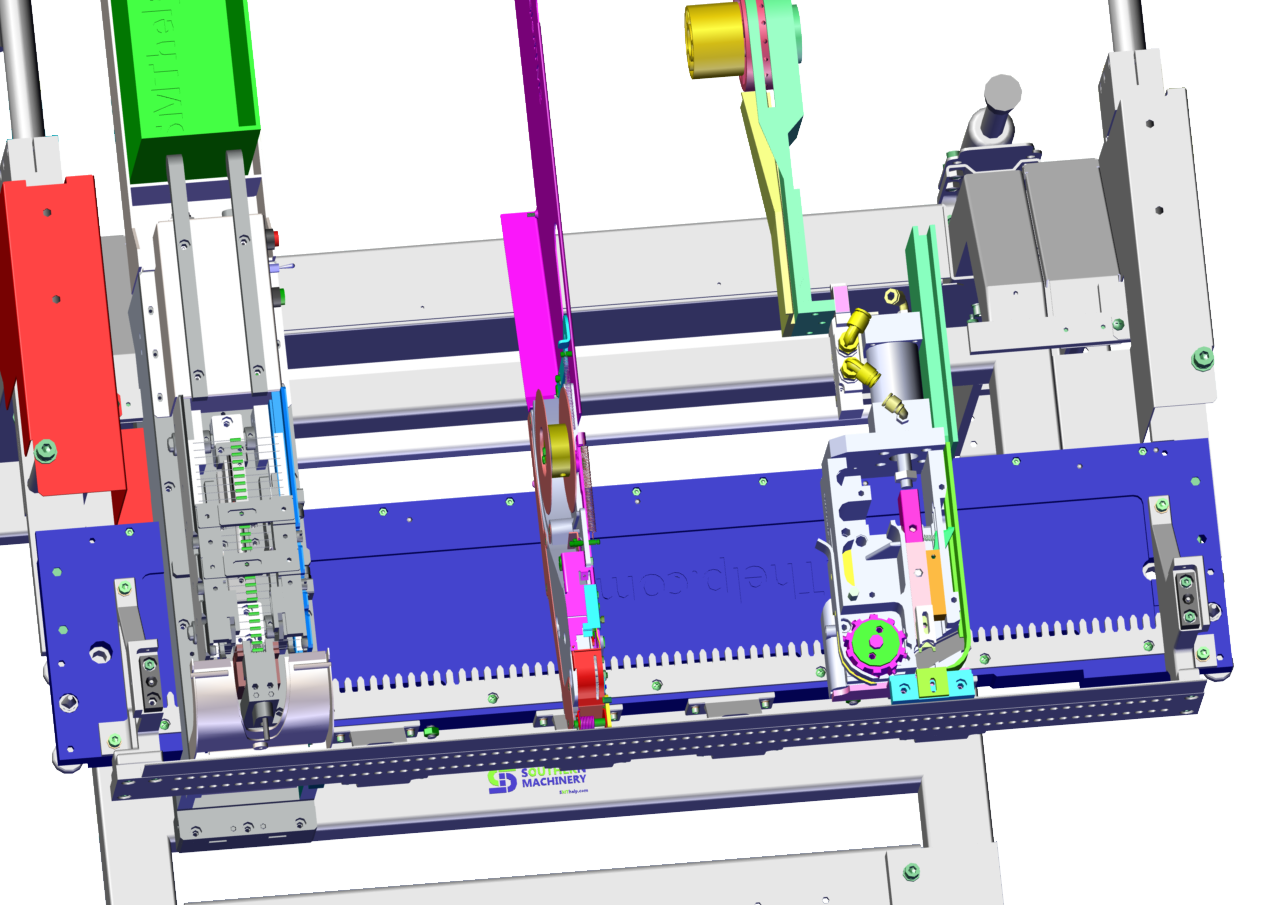

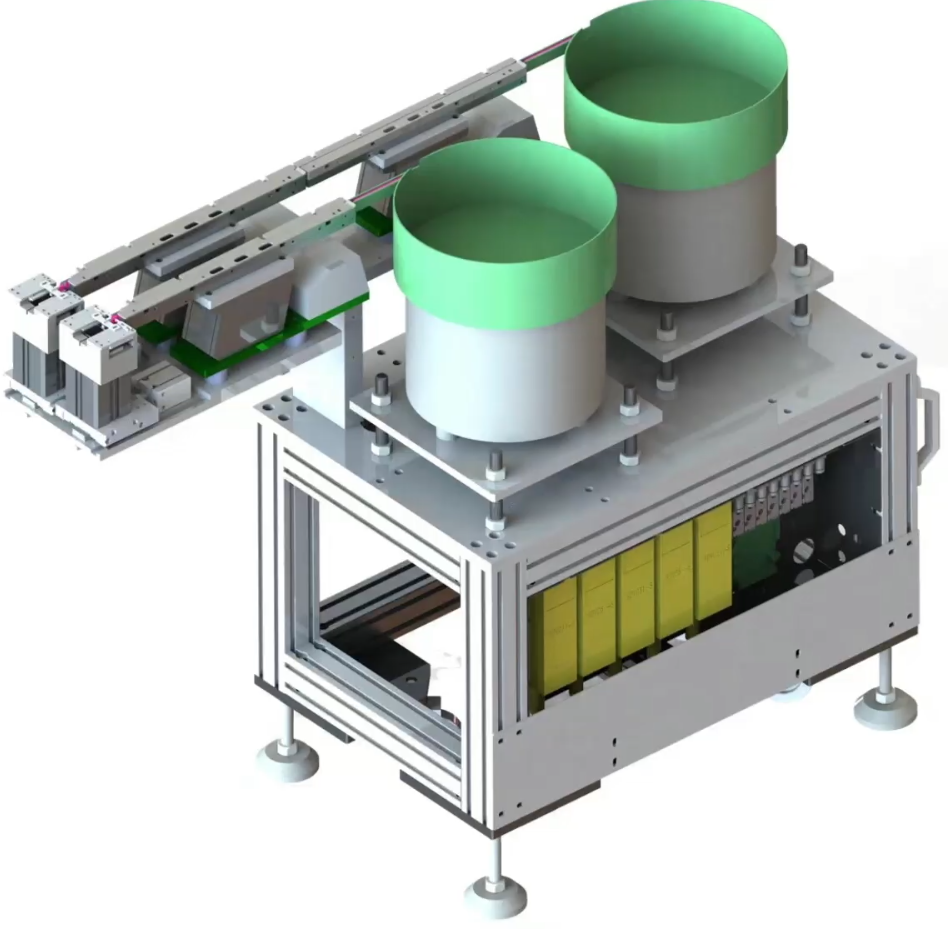

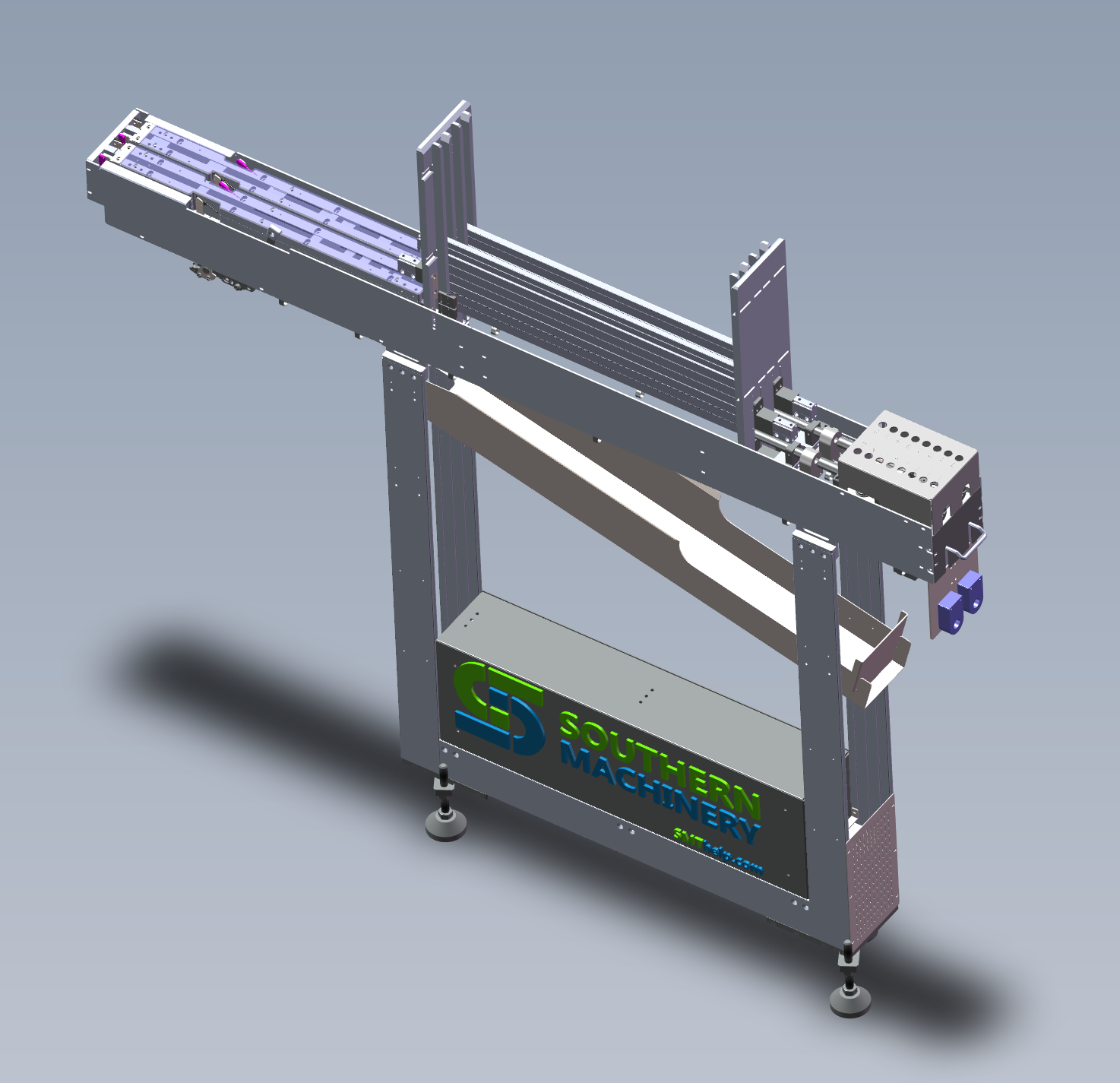

A bulk feeder is a device used to automatically feed bulk components into industrial processes at a controlled rate.How does a bulk feeder work?

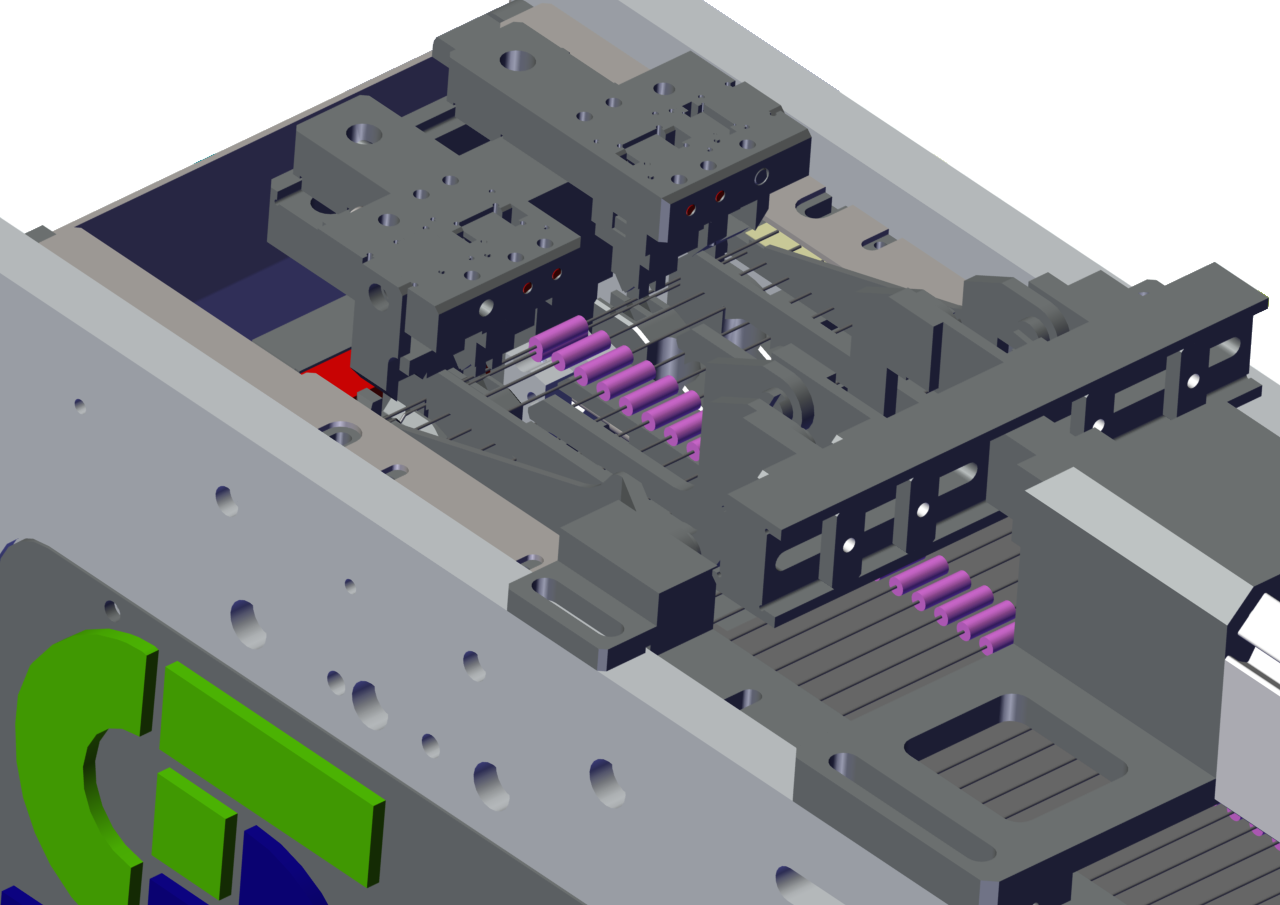

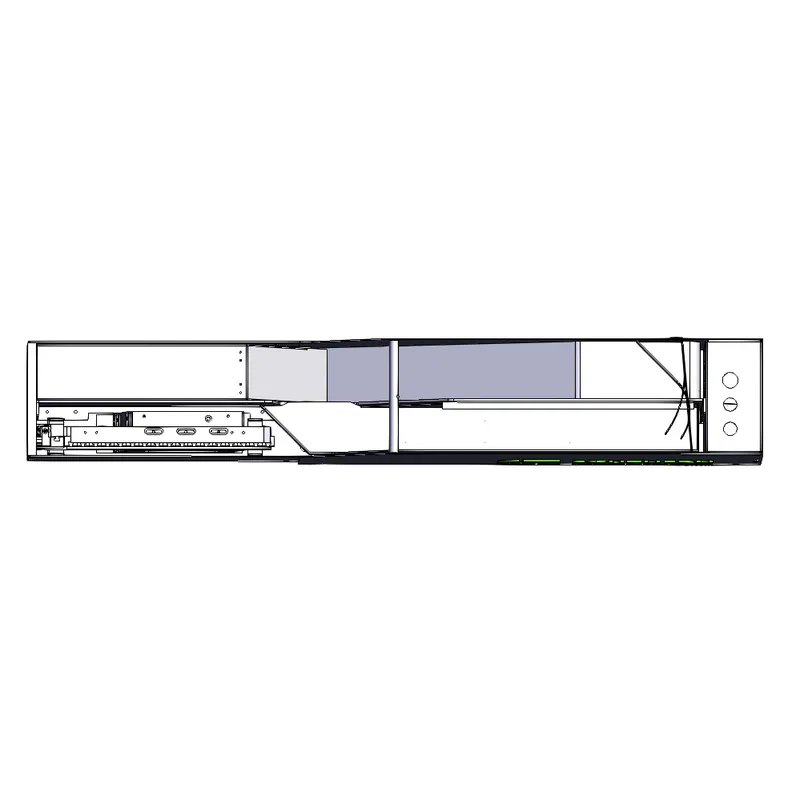

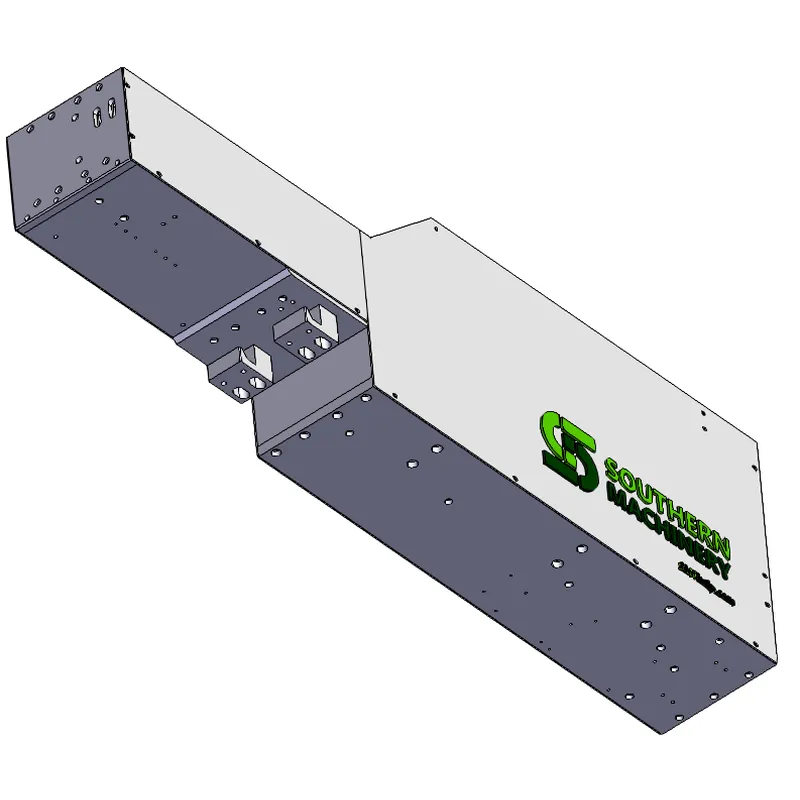

A bulk feeder uses a hopper to store the bulk component. An auger or belt under the hopper moves the component to the outlet at a controlled speed. Some feeders use weigh hoppers and control the auger speed to achieve a precise feed rate.What are the benefits of using a bulk feeder?

Bulk feeders can provide a continuous, automated, and accurate feeding of components. They reduce labor costs and improve the consistency and quality of industrial processes.What types of bulk feeders are available?

Common types of bulk feeders include screw feeders, belt feeders, vibratory feeders, drag chain conveyors, and weigh belt feeders.What components can be fed using bulk feeders?

Bulk feeders can handle a wide range of dry components including powders, granules, flakes, chips, fibers, and pellets. Sticky or abrasive components may require customized feeder designs.How are bulk feeders controlled?

Bulk feeders are often controlled by variable frequency drives which control the speed of the auger or belt. They can also be equipped with load cells, level sensors and mass flow meters to provide closed loop control of the feed rate.How are bulk feeders constructed?

Bulk feeders are typically constructed using stainless steel, carbon steel, aluminum or plastic. The choice of component depends on the mcomponent being fed and environmental conditions.What capacity range do bulk feeders cover?

Bulk feeders are available in feed rates ranging from a few pounds per hour up to 500 tons per hour or higher for very large industrial processes.How are bulk feeders maintained?

Bulk feeders require regular inspections, cleaning, lubrication, and testing to ensure optimal performance. Worn or damaged components should be replaced as needed to avoid downtime.Where are bulk feeders typically used?

Bulk feeders are widely used in industries such as food processing, chemical, plastics, mining, paper & pulp, wastewater treatment, and recycling.

Contact:

WhatsApp/Skype:+8615622888481

Email:jack@smthelp.com