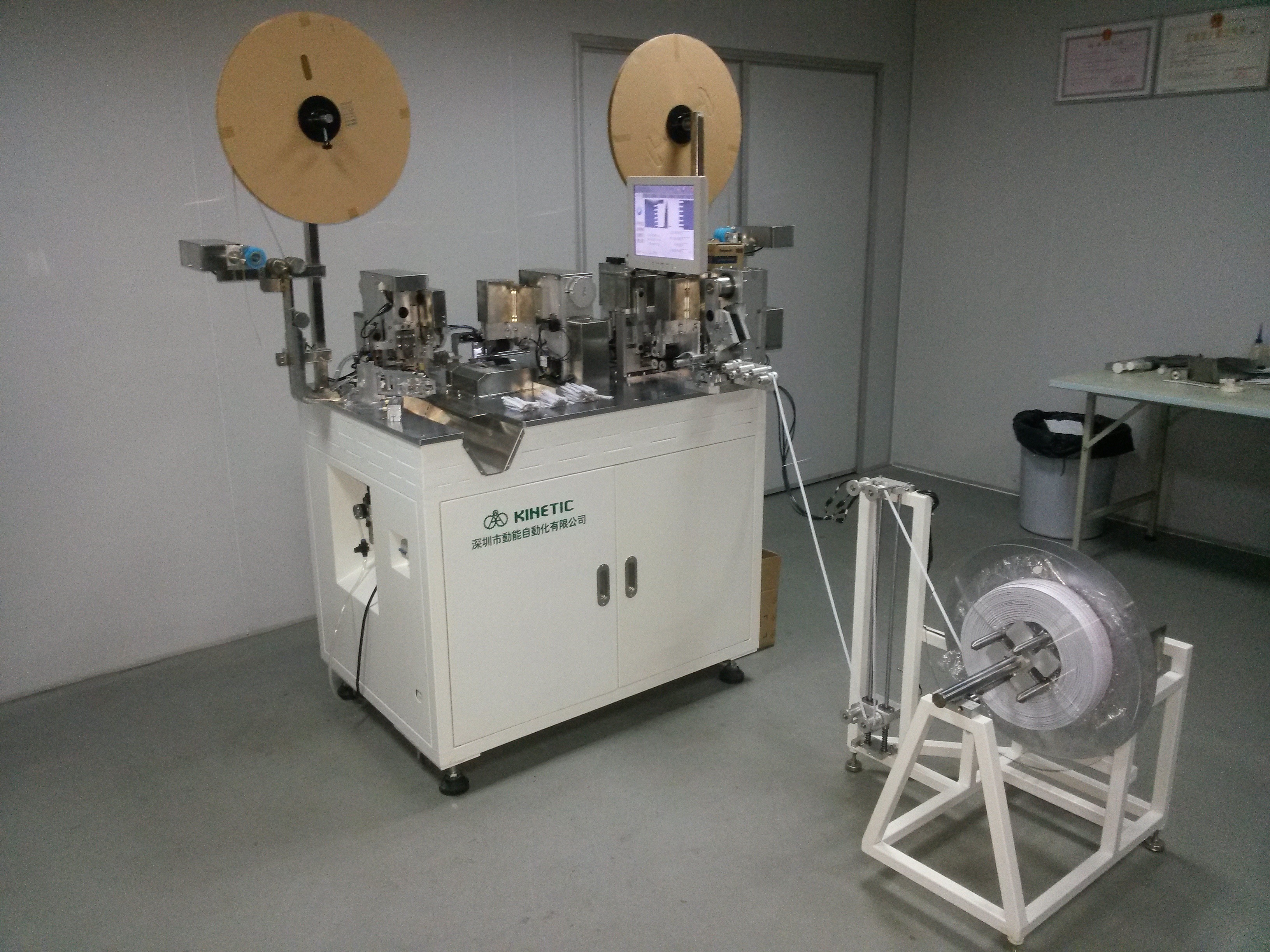

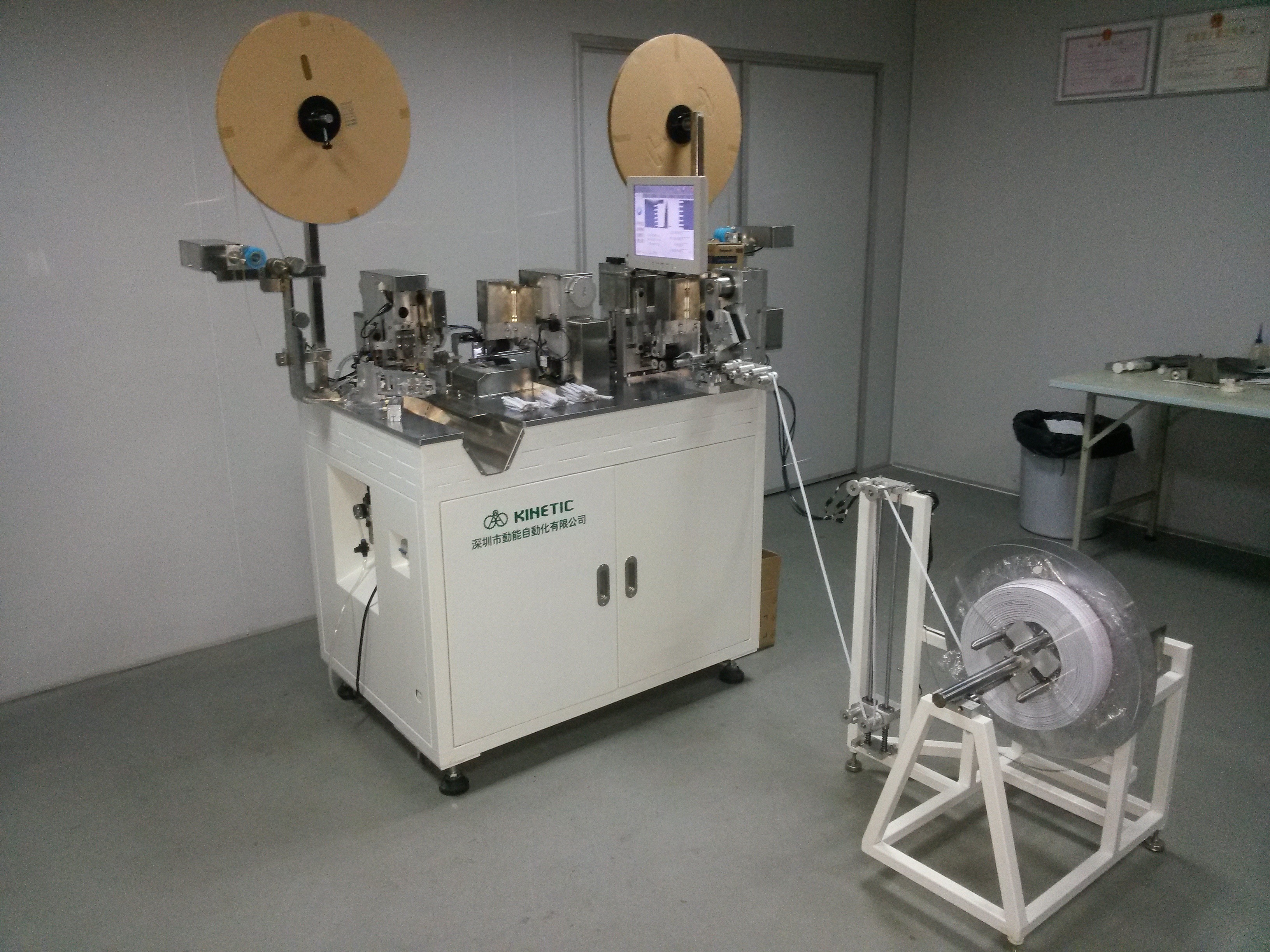

Full automatic cable/wire harness processing equipment for cable/wire cutting, stripping and terminal crimping. It’s feeding system, cutting and stripping system, mechanical hand clamping and transmitting system, twisting system, terminal crimping system and screen touch operation display, all integration technology of light, machine, air, magnetic were unified by the computer control. This technology is the most advanced at home or abroad.

Advanced detector which can detect no wires, wire overload ,wire deviation abnormal, less pressure ,stripping and crimping missing and other abnormalities with alarms.

Features

| 1.Wide capability: cable terminals like JC,PH,XH,EH,ZH, SCN,SM,VH,Dupont,etc. |

| 2. Cost-saving: all process complete automatically, save a lot of production cost. |

3. High stability: employ eccentric shaft mechanism for crimping, has balanced consistant crimping force to achieve high yield.

|

| 4.High precision: use stepping motor for cutting, branching and peeling length. Accuracy up to 0.1 mm. |

| 5. Accurate positioning: use Panasonic servo motor to control cable location, ensure the conductivity of cables and winding displacement. |

| 6.Crimping method: employ flipping structure enable upside down of cable. |

| 7. Small footprint: less than 1.5㎡ |

| 8.High efficiency: 18000 PCS/H, 24-hour operation. |

| 9.Easy setup: maintain several machines with simple training. |

| 10.Easy operation: touch screen operation, simple parameter setup. |

| 11.Intelligent control: adopt industrial computer control technology. |

| Item |

Parameter |

| footprint |

1.65mX0.75mX1.5m |

| Weight |

300KG |

| Air pressure |

0.4MPa-0.6MPa,(air source being flitterd and dried) |

| Voltage |

220V 50Hz |

| Power |

600W |

| Cable length |

>75mm |

| peel length |

2m-10mm |

| Cable type |

2468,gray-white line,blue-white line,red-white line,colorful line,etc |

| Max.cable width |

35mm |

| Wire diameter |

0.8mm-3.0mm |

| Efficiency |

18000PCS/H(10 pin cable) |

| Special functions |

single or double end crimping;interleaving crimping, cable flipping. |

Winding Displacement Terminating Machine/Double-end Winding Displacement Ternimal Crimping Machine from

Shenzhen Southern Machinery Sales And Service Co., Ltd