Southern Machinery provides professional SMT peripheral equipment.

- THT Chatbots

- Home

- Machines

- Accessory

- Support

- About Us

- blog

- Contact

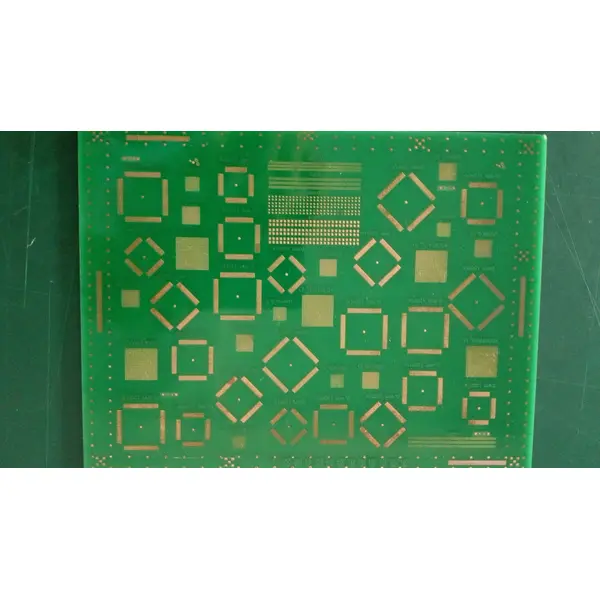

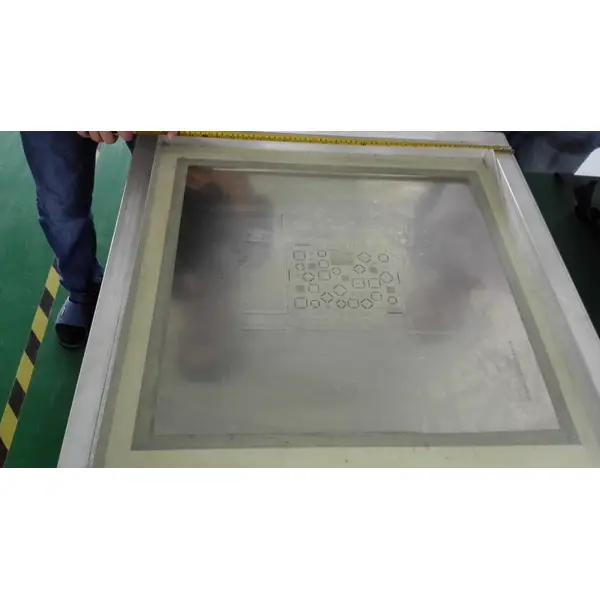

Stencil Cleaner for cleaning various stencils and misprinted PCBs, the combination of features offered by our S-1688 make it a unique and truly automatic stencil cleaner. The threshold for usefulness of automation is allowing the operator to walk away from the process without worry. Normally, stencil cleaners require manual positioning and movement from experienced operators to ensure consistent cleaning. The S-1688, from start to finish, is a closed cleaning system that does not require experienced operators or any repositioning. It is the easiest solution for ease of operation, fire safety, chemical safety, and the environment.

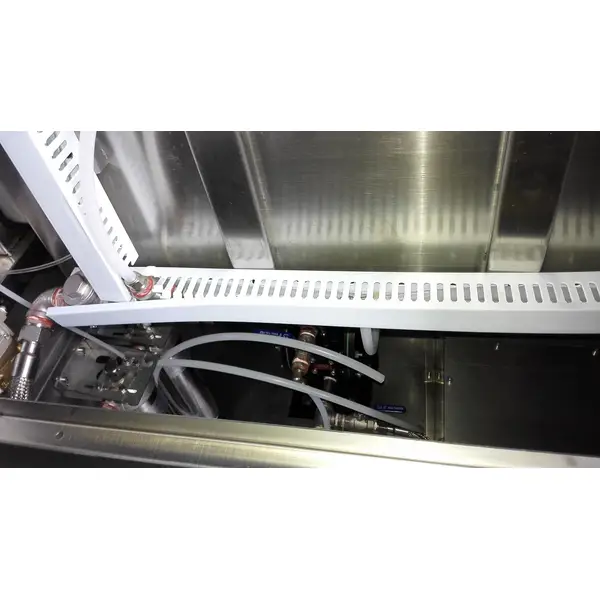

The S-1688 frees operators by performing the following operations automatically: combining a specifically shaped ultrasonic cleaning chamber, continuously filtering the cleaning bath, automatic indication of liquid level and filter status, and automatic loading/unloading of the stencil. Its integrated loading arm ensures that every stencil is positioned precisely the same way inside the cleaning tank and that it is withdrawn from the cleaning chemicals as soon as the cycle is finished. Its filtration system continuously removes solids from the cleaning liquid, often maintaining the cleaning effectiveness of the medium for up to a year or longer (depending on usage, of course).

Usage: Can effectively remove solder paste, such as red glue residue and more from steel mesh, wire mesh, copper mesh, microporous network, scraper, fixture, PCB, etc.

[su_button url=”http://www.smthelp.com/get-a-quote/” background=”#00a3b3″ size=”5″]REQUEST A QUOTE[/su_button]