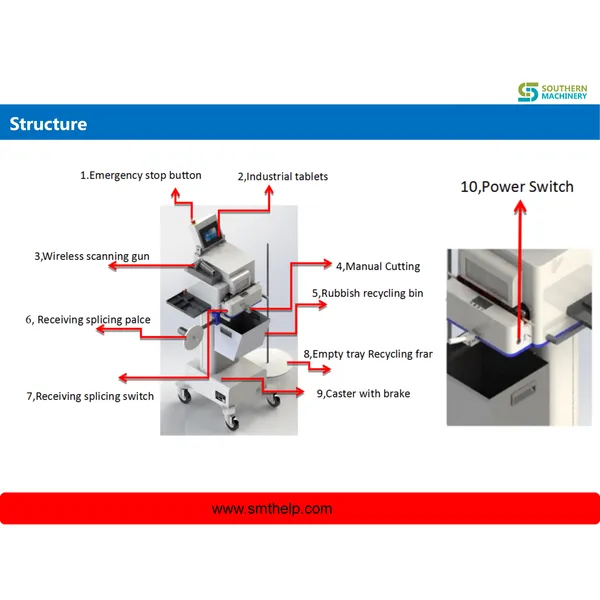

SMT AUTOMATIC SPLICING MACHINE(MES)

SMT AUTOMATIC SPLICING MACHINE(MES)

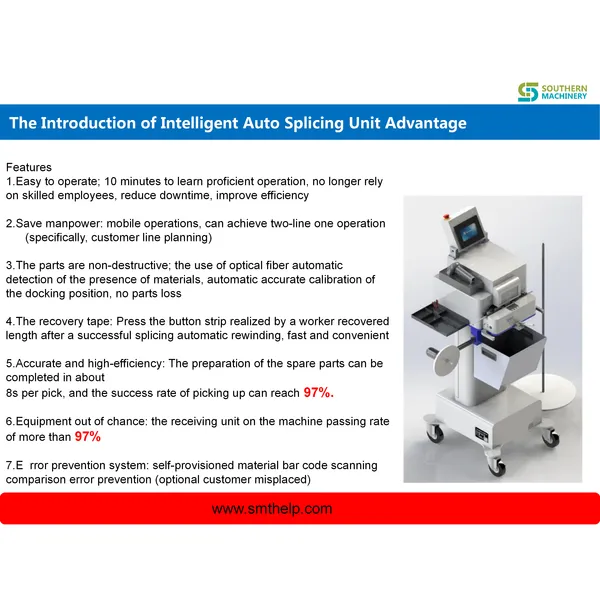

Features of machine:

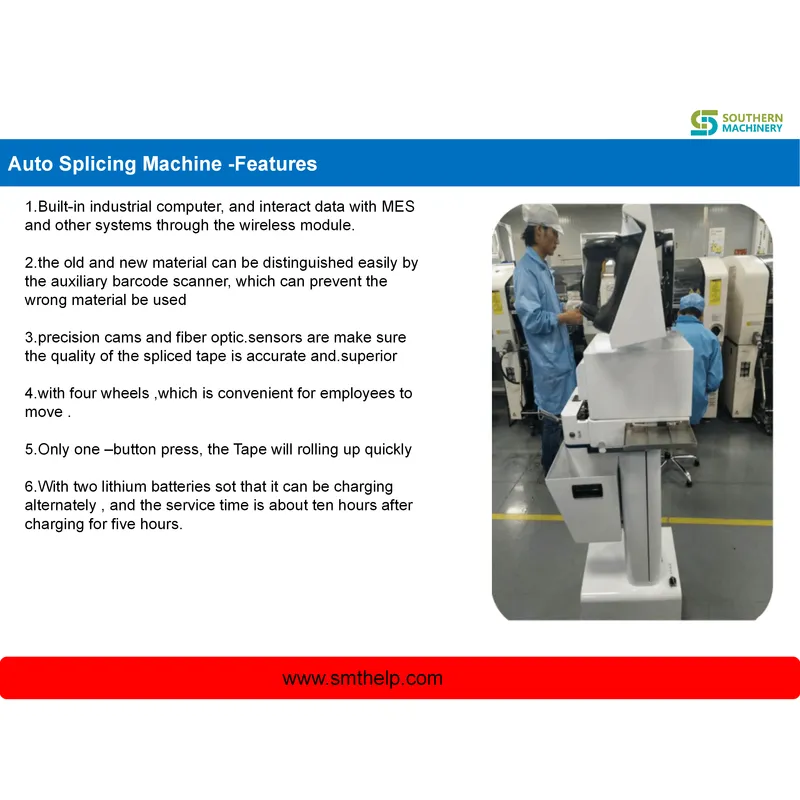

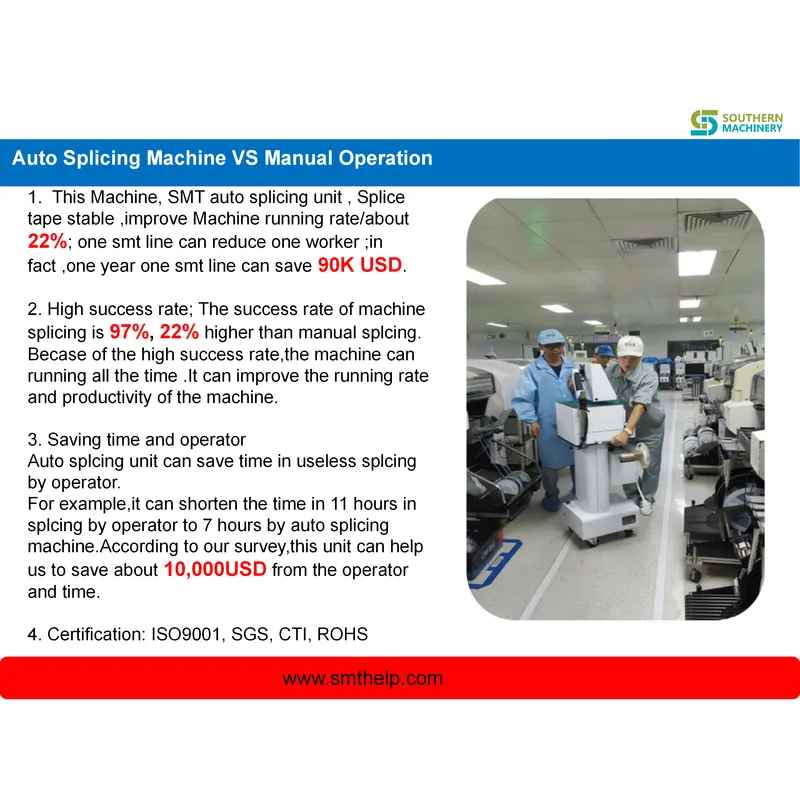

1、Simple operation: 10 minutes of study can be skilled operation, no longer rely on skilled staff, reduce downtime and improve efficiency.

2、Economize on manpower: Mobile operation,which can realize two-lines and one-person operation (the specific situation depends on the client line body planning).

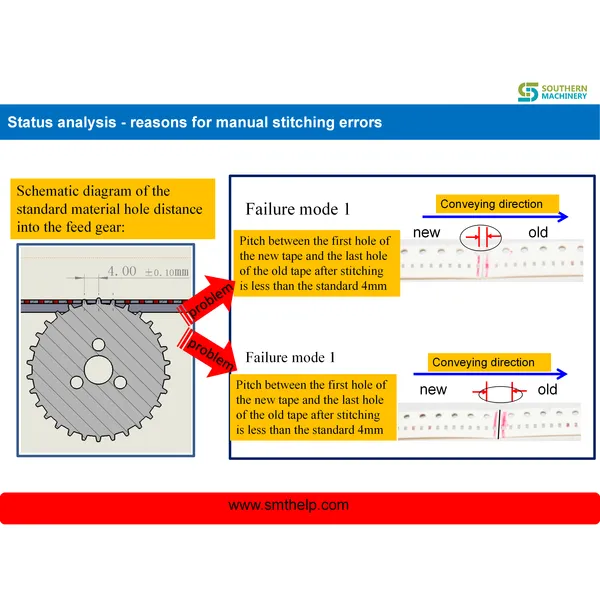

3、No part loss: Use optical fiber to automatically detect the presence of materials and automatically and accurately calibrate the splicing position, no part loss .

4、Material strap recycle: It’s convenient and efficient for operators to long press the unloading switch to automatically recycle the tape.

5、Accurate and efficient :It only takes about 8 seconds and success rate up to 97%.

6、Pass Rate:over 97%

7、Fool-Proof System: Equipped with bar code scanning material function(optionally connected to the customer Fool-Proof system)

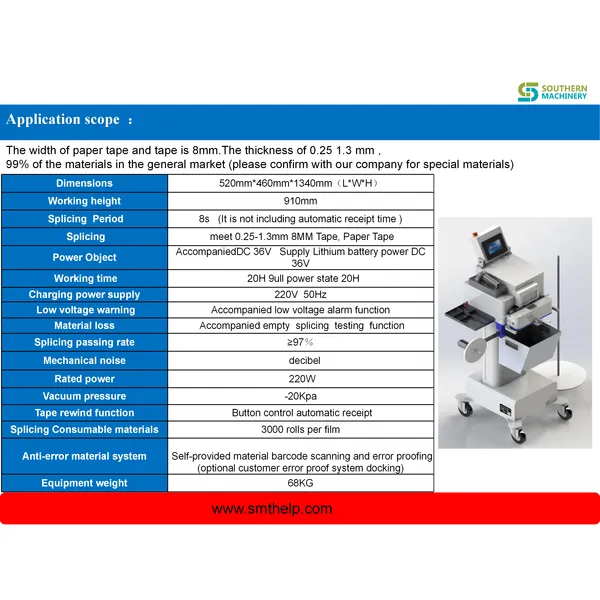

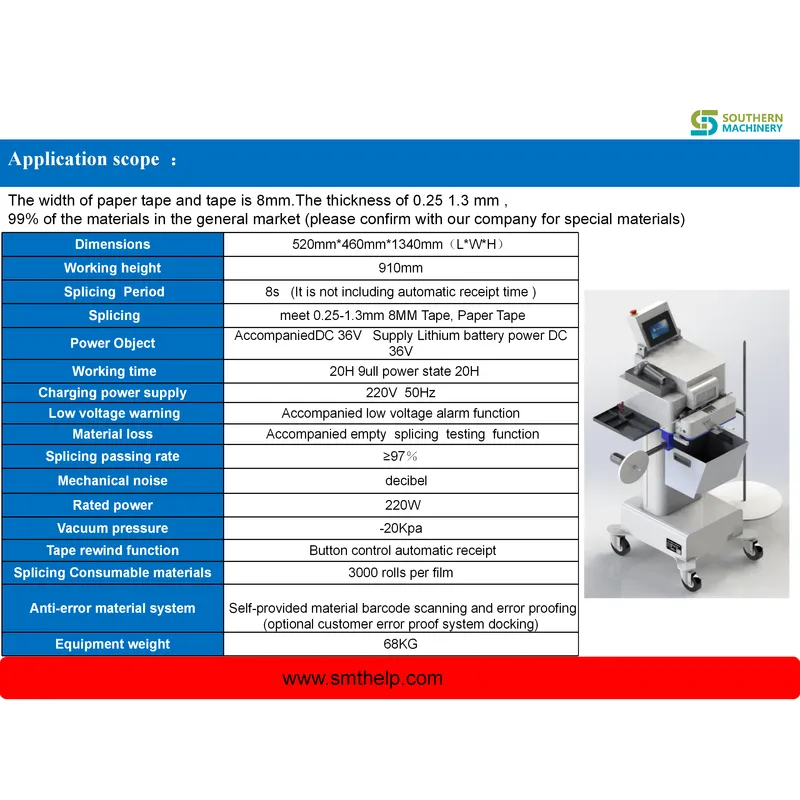

Technical parameter

| Product size | L520mm*W460mm*H1340mm |

| Operation height | 910mm |

| splicing cycle | 8s(Automatic unloading time is not included) |

| Connection precision | 0.1MM |

| Application | Adhesive tape and paper tape (thickness :0.25-1.3mm,width:8M) |

| Power supply | lithium battery DC 36V or 24V |

| Work Period | >16h with a full battery |

| Charging voltage | 220V 50Hz |

| Low voltage alarm function | The machine is equipped with low power alarm to remind you to recharge or replace the battery |

| Material loss | Equipped with empty material position detection function |

| Pass rate of splicing | ≥97% |

| Mechanical noise | <50 decibel |

| Rated power | 150W |

| Vaccum pressure | -30Kpa |

| Material strap wrapup function | Button control can automatically picking the material |

| Auxiliary material | 3000 pieces of tape per roll |

| Fool-Proof System | Equipped with bar code scanning material function(optionally connected to the customer Fool-Proof system) |

| Product weight | 68KG |