High-speed Smt Led Pick And Place Machine,Smt Automatic Led Pick And Place Machine,Led Pick And Place Machine:

High-Speed Dedicated smd chip mounter machine Assembles LED PCBs Up to 1.2 Meters Long in a Single Pass

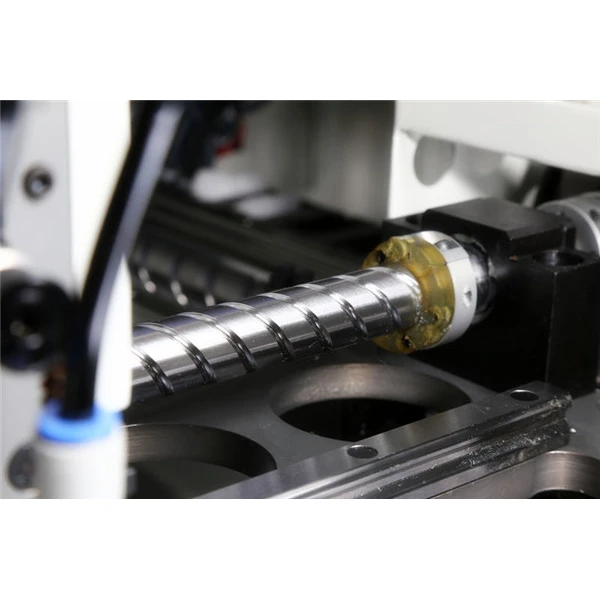

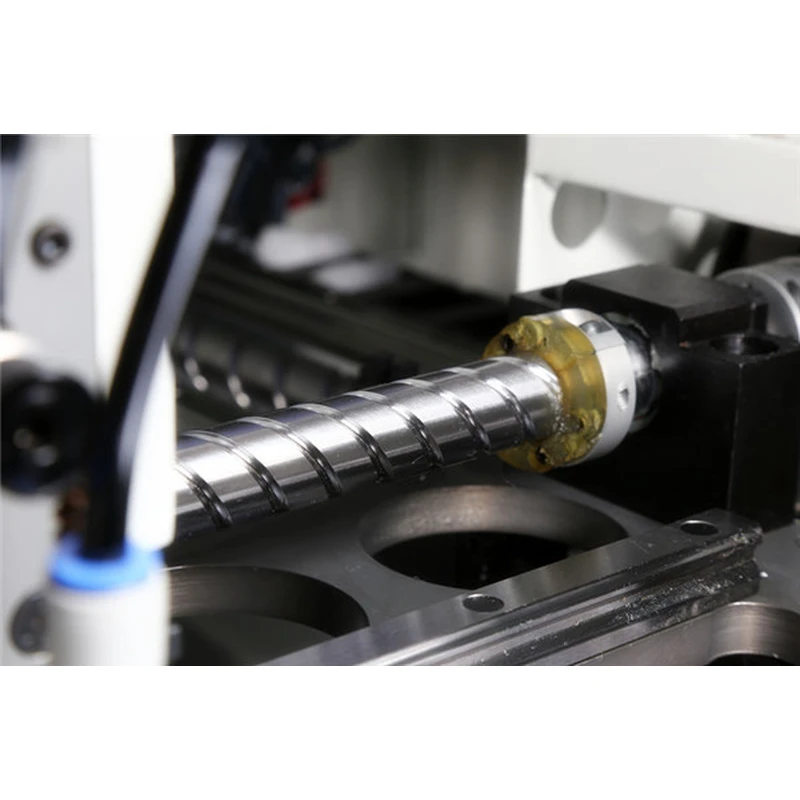

Assemble LED lighting products, including long tube boards and flexible strips, at speed reaching 15,000 LEDs per hour with the high-speed, dedicated S-E20000 chip mounter, available with 1200 mm (47.3″) max board length.

Product Description

S-E20000 smd chip mounter machine – General Specifications