We design and manufacture Auto Insertion and SMT Machines for Electronic PCB Assembly.

Specialize in Auto Insertion machine and SMT equipments, providing spare parts, sub-assembly, retrofit kit, repair kit, upgrading, training,overhaul service.

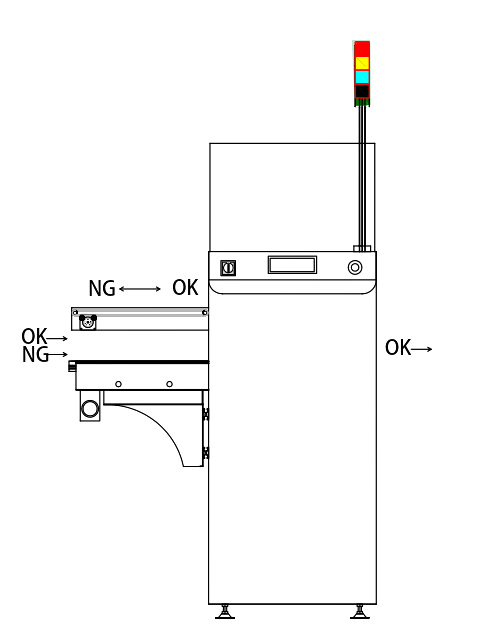

PCB invertor / PCB flipper for double-sided process

Description

This unit is used to invert PCBs (180°) for “double-sided” process

Features

User friendly ‘soft touch’ LED membrane control panel

Enclosed design with torque limiter to ensure highest level of safety

‘Top cover’ can be opened for easy access to hardware during maintenance

Smooth and precise inverting motion(leadsrew)

Subsequent inversions continue from the last unloading position (short cycle time)

Different sizes avaiable upon request.

SMEMA compatible

Specification

| Model | SBI330 | SBI460 |

| Dimension (L*W*H): | 500*786*1200mm | 600*856*1200mm |

| PCB Size (mm): | 50*50-445*330mm | 50*50-530*460mm |

| Cycle Time: | Approx.5 seconds | Approx.5 seconds |

| Belt Typle: | Oblate belt | Oblate belt |

| Power Supply: | AC 110V or 220V, single phrase | AC 110V or 220V, single phrase |

| Power: | Max 150VA | Max 150VA |

| Air Pressure & Air Consumption: | 4-6bar, 1.ltr/min max | 4-6bar, 1.ltr/min max |

| Transport Height: | 900±20MM (or customer specified) | 900±20MM (or customer specified) |

| Transport Direction: | L to R or R to L | L to R or R to L |

| Weight (kg): | 120 KG | 160 KG |

| SMEMA compatible | YES | YES |

| Model | Dimension (L*W*H.MM) | PCB size(MM) | Weight(KG) | PCB Thickness |

| SCN250 | 500*563*1200 | 50*50-330*250 | 150KG | 0.6~4 mm |

| SCN330 | 580*643*1200 | 50*50-400*330 | 170KG | 0.6~4 mm |

SMEMA compatible

BHS video

More pictures please click SMT THT Albums

Looking for 3D machine model please click SMT Machine 3D Drawing

Looking for SMT machine Catalog please click SMT Machine Catalog

Call to discuss SMT machine please click WhatsApp SMT

Email to SMT Specialist please click SMT Specialist