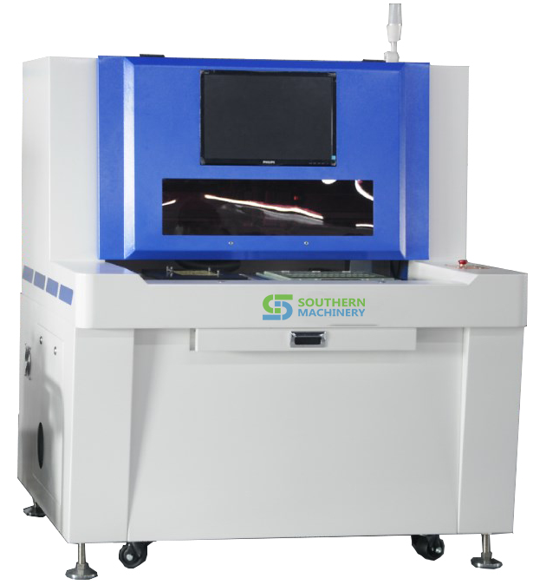

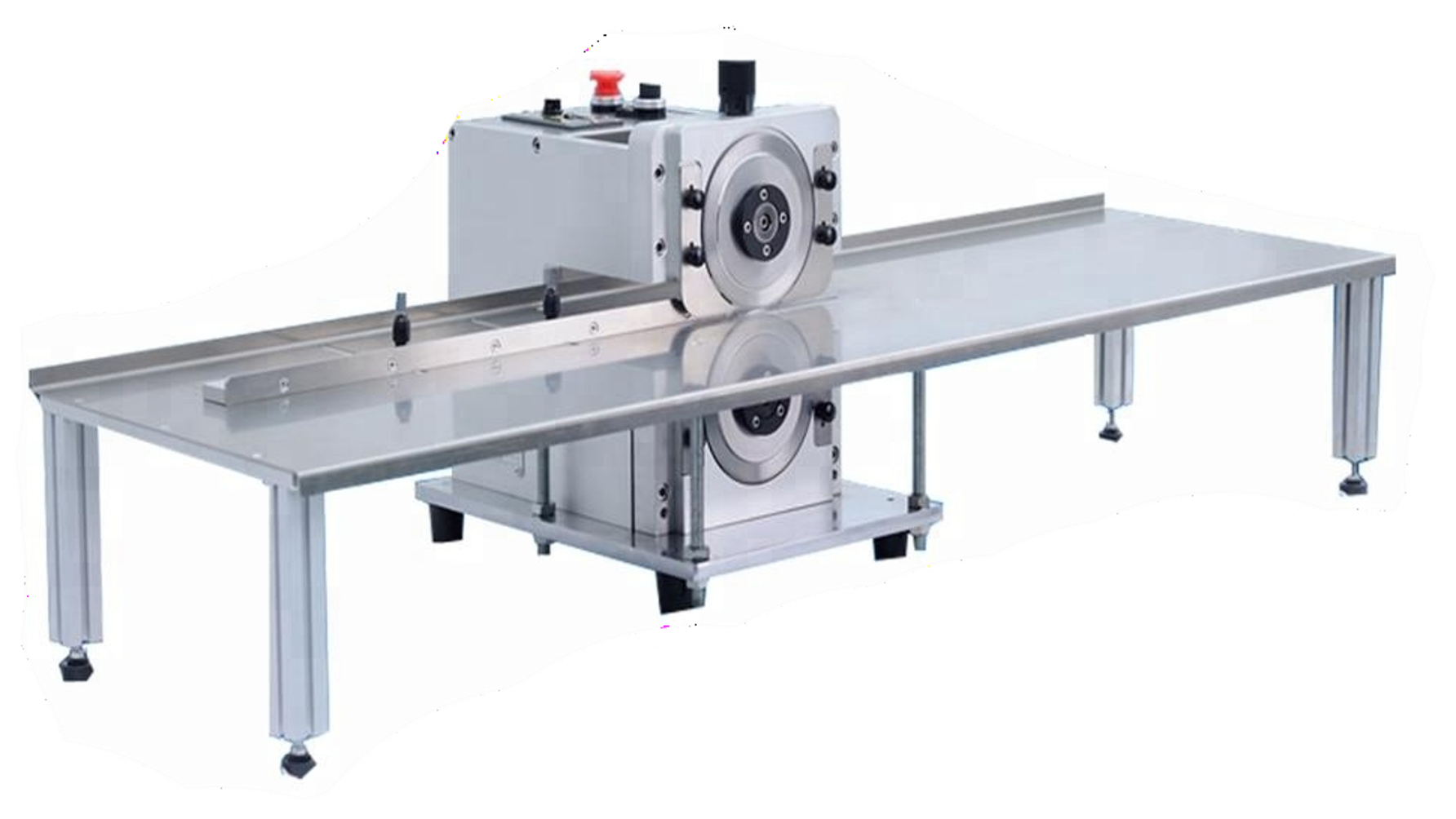

The S-D509 automated V-cut PCB separator is designed for high-volume manufacturing of all types of V-scored printed circuit boards. This programmable machine precisely cuts PCBs to specified lengths at adjustable speeds up to 500mm/s, eliminating the inaccuracies and inefficiencies of manual separation methods. With a cutting length range of 0 to 500mm and blades adjustable from 0 to 2mm in height, the S-D509 can handle PCBs of any width and thickness from 0.2 to 5.0mm. Operators simply enter the desired cut length and the machine automatically stops at the correct position for each PCB. An optional conveyor belt smoothly transports finished boards out of the machine. Adjustable stop blocks can also be employed to further streamline the process for different PCB models. The movable cutting blades allow quick adjustments to suit various V-slot depths.The S-D509 improves productivity through speed, automation, and customization. Cutting speeds can reach up to 500mm per second, and the programmable controls enable pre-setting specific cut lengths to automatically stop the machine. Rather than a fixed platform height, the table can adjust from 0 to 50mm to fit PCBs of different thicknesses. These features eliminate the time-intensive adjustments and inaccuracies of manual V-cut methods.With professional V-cut PCB separation equipment like the S-D509, electronics manufacturers can avoid the issues of manual breaking including slowed production time, uneven edge quality, and widthwise cracks in the PCB. The automated precision cutting process results in smooth edges, minimal debris, and lower costs through optimized efficiency.Smart EMS partners with companies to improve manufacturing productivity through customized automation solutions. We provide professional equipment including PCB separators, wave soldering machines, PCB conveyors, and SMT pick and place machines. Our team helps determine the appropriate level of automation based on production requirements and budget.The S-D509 V-cut PCB separator's movable cutting blades, customizable speeds, and automation features make it the ideal solution for high-volume electronics manufacturers seeking to improve productivity and quality. This professional machine eliminates the problematic issues caused by manually breaking V-scored PCBs. With Smart EMS automated equipment and process optimization, companies can gain a competitive advantage through increased output, consistent quality, and reduced long-term costs.

velocidade de corte ajustável, alta de 500 mm/s e baixa de 300 mm/s, velocidade mais alta pode melhorar o resultado do corte, afastando as placas das rebarbas.

Comprimento de corte: 0~500mm e 0~360mm (comprimento da lâmina pode ser personalizado) leve ajuste da altura da lâmina em 0~2mm, altura da plataforma ajustável em 0~50mm, para encaixar PCB de diferentes espessuras e resolver o problema de diferentes V-slots profundidade

Defina manualmente a posição para parar automaticamente de acordo com o comprimento específico do PCB.

Não há restrição na largura do PCB de destino, o comprimento máximo de corte é de 500 mm, espessura do PCB: 0,2 a 5,0 mm, espessura máxima V-slot: 0,25 a 2,0 mm

A correia transportadora é opcional, transfere convenientemente o PCB acabado.

O bloco de parada pode ser usado para diferentes PCBs, para aumentar a eficiência de trabalho

Máquina separadora de PCB profissional com corte em V com lâmina de corte móvel

Especificação

Detalhes do contato

Bem-vindo a entrar em contato e obter mais informações:

E-mail: wayne@smthelp.com

Skype: waynesmt@outlook.com

Whatsapp/WeChat: +86 15817498429