A Southern Machinery, fornecedora profissional de máquinas de solda Wave, tem experiência em soluções THT. Nós fornecemos todos os tipos de máquinas de solda Wave.

A máquina de solda por onda S-WS450C e a máquina de solda por onda S-WS250 são as mais vendidas de todas. A Wave Soldering Machine é usada para soldar o estanho líquido no PCB.

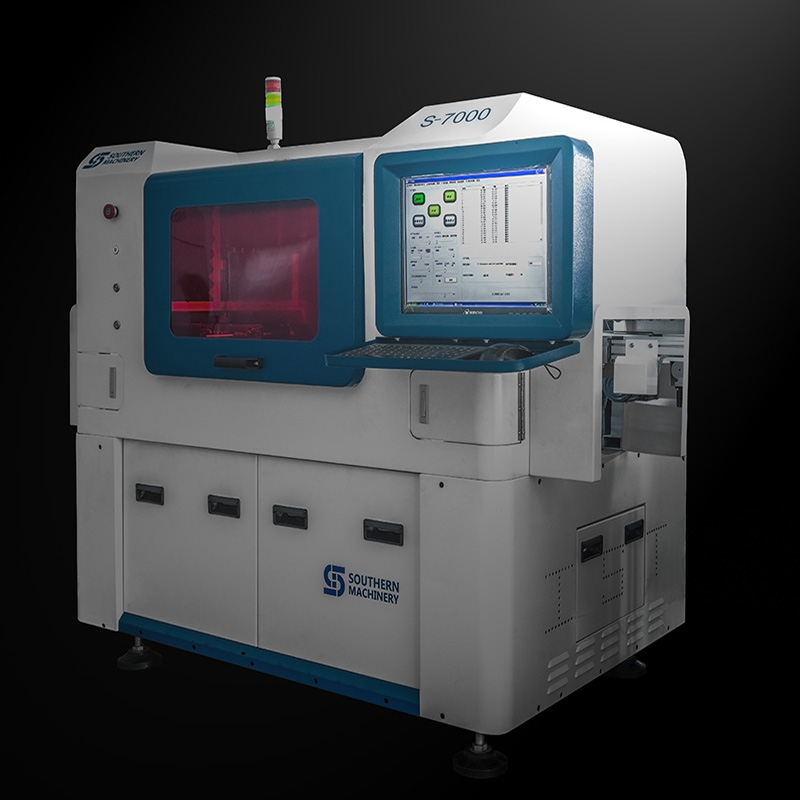

Máquina de solda por onda S-WS250:

Product Characters:

1.Suitable for the welding device of long legs and SMD, SMC components

2.Lead-free soldering process, accord with the requirement of environmental protection industry

to reduce pollution

3.Directly pull out of the preheating zone of the module design and filter system, convenient

maintenance

4.Lengthening preheating zone and preheating curve smoothly, ensure the PCB uniform heat, not

deformation

5.Intelligent automatic tracking spray system, the area of the spray along with the PCB evenly

heat, not deformation

6.With speed automatic tracking program

7.With flux nozzle automatic cleaning device, use for a long time, without cleaning

8.Furnace adopts the XT special structural design, can save electricity and reduce oxygen cargo

9.Guide rail USES the XT unique design, can greatly reduce the thermal deformation, can

guarantee the PCB is complete, welding and transport

10.The stepless frequency conversion technology, precise control wave height

11.All motor is equipped with overload protection system

12.Precision titanium alloy elastic titanium claws, transportation, PCB, stable and reliable and

never adhered tin

13.The whole control system adopts three ling series PLC and touch screen

14.Furnace and nozzle uses the XT unique design, two tin bath outside heating type to prevent tin

explosion and decrease the oxidation

Specification:

Model : S-WS450C

PCB adjustable width: Max.50~450MM

PCB transport height: 750 ± 50 mm

PCB best welding speed: 1500-1800 – mm/Min

(welding Angle) : 3 ~ 7 degrees

Welding Angle display: Gravity Angle display

Element height restrictions: Max.150mm

Wave height range: 0-15 mm flat

Wave number: 2

Preheating zone length: 2000 mm

Number of preheating zone: 4

Preheating zone power: 8 kw

Preheating zone temperature: room temperature to 250

℃ adjustable

Heating method: hot air

Number of cooling zone: 2

Cooling: forced cooling fan

Cooling area: 2

Apply solder type: lead-free solder

Tin furnace power: 12 kw

Dissolve tin amount : Approx. 450 kg

Tin stove material: nodular cast iron

Tin tin stove type: 4th generation and energy saving

furnace (50-350 adjustable)

Tin stove temperature: room temperature to 350 ℃, the

control precision ± 1 – 2 ℃

Tin stove temperature control precision: ± 1°

Solder height detection: conductive type probe detection

Solder add: manual

Temperature control mode: P.I.D + SSR

The whole machine control mode: PLC + PC

Flux addition method : chemical pump automatically added

Flux flow: 10 ~ 100 ml/min,

Spray way: Japan sanyo stepper servomotor + Japan ST – 6 nozzle

Flux recovery: tray recycling

Power supply: 3 phase 5 wire 380 v

Start the power (total power) : Max. 22 kw

Normal operation of the power: Approx. 3-5 kw

Air source: 4 ~ 7 kg/CM2

Installation dimensions: L4500 *W1400 *H1650MM

Weight: Approx. 1500 kg

Nitrogen concentration: Customer’s homemade nitrogen

concentration of 99.99%, we can reach 1000 PPM for nitrogen

dispositivo de tubulação

Consumo de nitrogênio: 10-25 m3 / h

Mais fotos, clique em Álbuns SMT THT

Procurando o modelo de máquina 3D, clique em Desenho 3D da máquina SMT

Procurando Catálogo de máquinas SMT, clique em Catálogo de máquinas SMT

Ligue para discutir a máquina SMT, clique em WhatsApp SMT

E-mail para Especialista SMT clique em Especialista SMT